Automobile belt pulley electroplating equipment

A technology of electroplating equipment and pulleys, which is applied in the electrolysis process, electrolysis components, cells, etc., can solve problems affecting quality, uneven electroplating, and electroplating effects in holes and bottoms of holes, etc., to prevent pollution, improve electroplating quality, and ensure The effect of finished product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

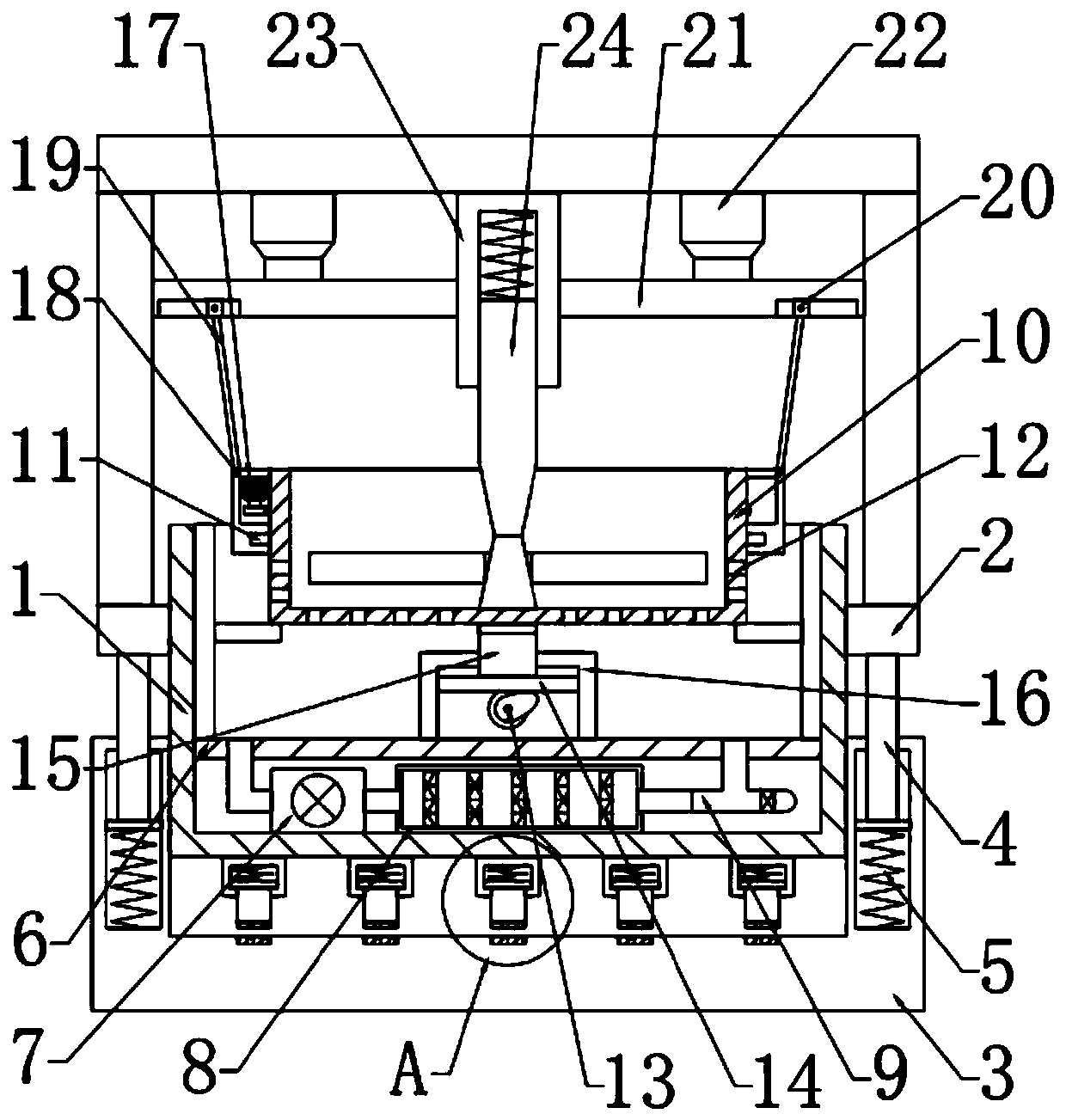

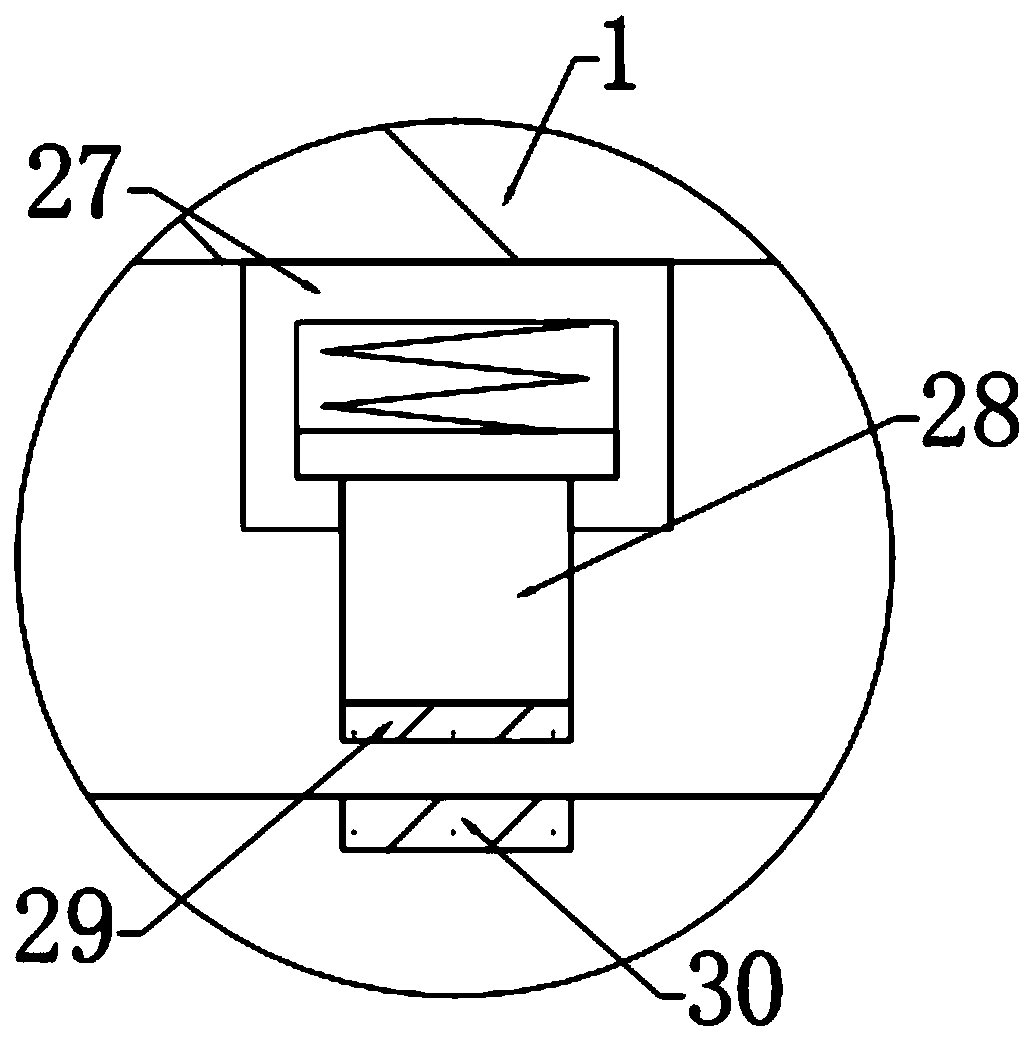

[0026] see Figure 1-3 , in an embodiment of the present invention, an automobile pulley electroplating equipment includes an electroplating tank 1, the left and right sides of the electroplating tank 1 are fixedly connected with support blocks 2, and the bottom of the support block 2 is provided with a shock absorbing mechanism. The top of the support block 2 is fixedly connected with a fixed bar, and the top of the fixed bar is fixedly connected with a top plate, and the underside of the top plate is provided with a placement mechanism for fixing the pulley, and the placement mechanism is connected with the top plate by a lifting mechanism.

Embodiment 2

[0028] In this embodiment, the lifting mechanism includes a connecting plate 21 arranged on the lower side of the top plate, the connecting plate 21 is slidably connected with the support rod, and a telescopic rod 22 is fixedly connected between the connecting plate 21 and the top plate.

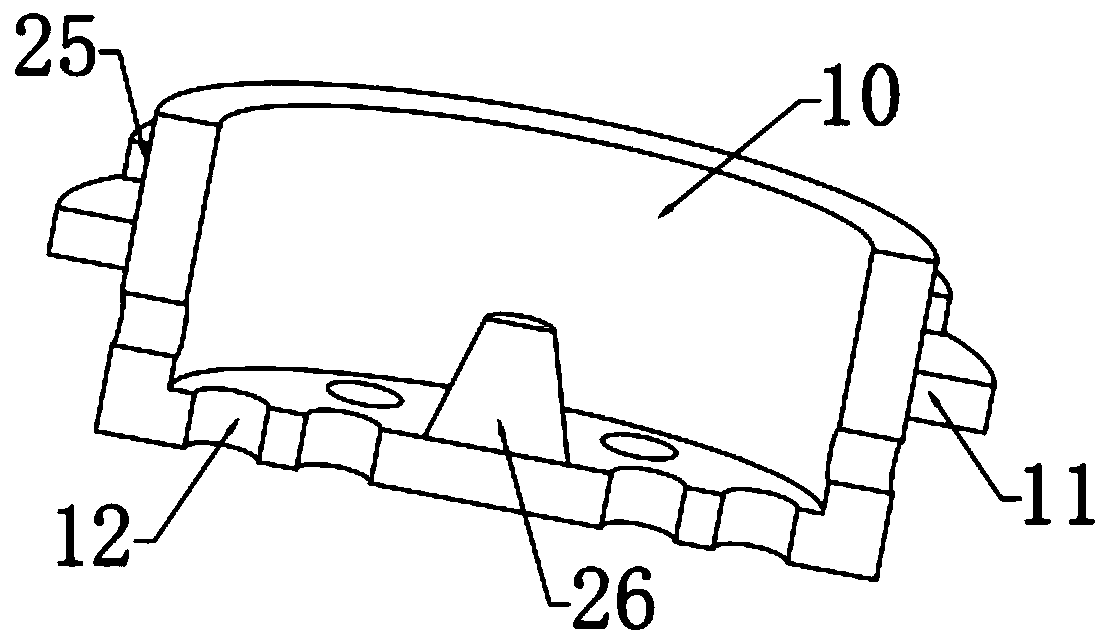

[0029] In this embodiment, the placement mechanism includes a placement tray 10, which is provided with a plurality of through holes 12 for feeding in and out of the plating solution, and the bottom of the inner side of the placement tray 10 is fixedly connected with a placement tray for placing pulleys. Block 26, the outer top of the placement tray 10 is fixedly connected with a turntable 11, the outer side of the turntable 11 is rotatably connected with a connecting block 17, the top of the connecting block 17 is hingedly provided with a connecting rod 19, and the other end of the connecting rod 19 Hinged with the slider 20, the slider 20 is slidably connected with the chute arranged at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com