Fusion structure of umbrella-shaped body expanding device and easy-to-cut anchor rod or recoverable anchor rod cable

An easy-to-cut, anchor cable technology, which is applied in the direction of foundation structure engineering, construction, sheet pile walls, etc., can solve the problems of inner anchor head drop, large deformation, large creep, etc., and achieve the effect of simple recruitment procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The relevant components in the fusion structure in this embodiment not only adopt the existing technologies in the umbrella-shaped expansion device, easy-cutting anchor rod, and recyclable anchor cable, but also add various structural components and setting methods according to different fusion methods ,Instructions.

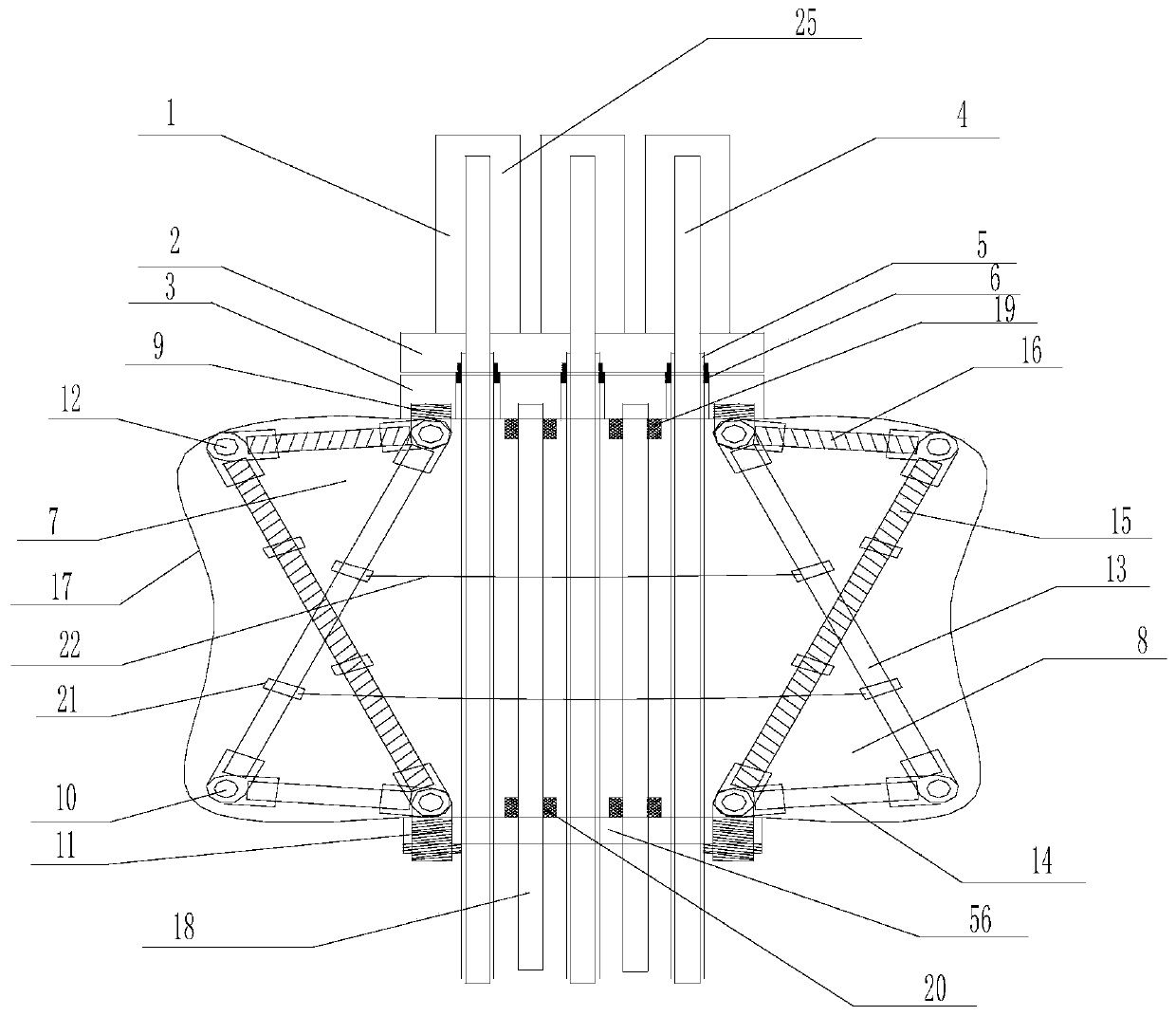

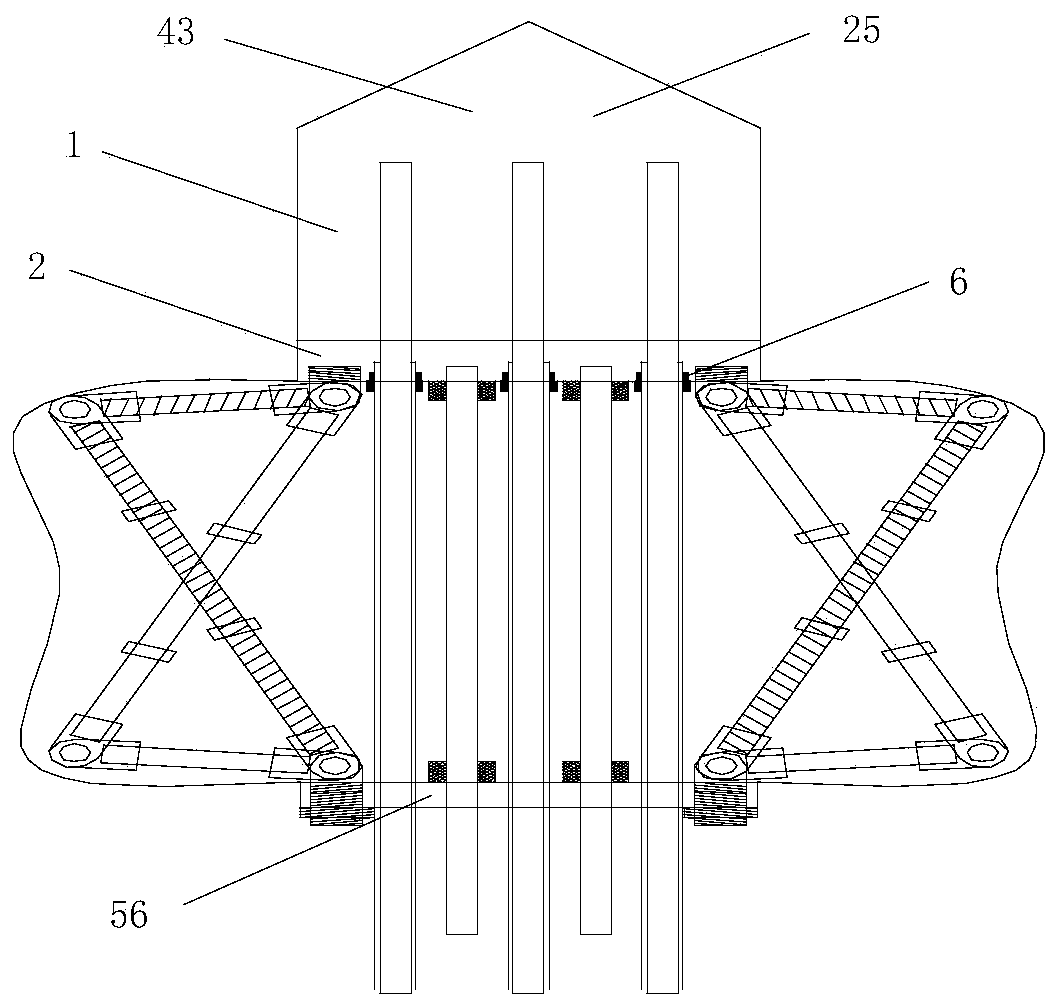

[0039] The fusion structure of the umbrella-shaped body expanding device and the free-cutting anchor rod or the recyclable anchor rod cable, the tension plate 3 of the umbrella-shaped body expanding device and the bearing plate 2 of the easy-cutting anchor rod or the recyclable anchor rod cable are combined; or The rib tray 3 is arranged behind the loading plate 2 and the rib tray 3 is in contact with the loading panel 2; or the rib tray 3 is arranged behind the loading panel 2 but the rib tray 3 is not in contact with the loading panel 2; or the loading panel 2 and set in combination with the rib plate 56; or the bearing plate 2 is arranged behind the ri...

Embodiment 2

[0086] Example 2: figure 1 Shown is a recyclable anchor cable, the split inner anchor head 1 is fixedly connected to the bearing plate 2, and the bearing plate 2 is installed on the front side of the tendon plate 3; figure 2 Shown is a recyclable anchor cable, the integral inner anchor head 1 is fixedly connected to the bearing plate 2, and the bearing plate 2 and the tendon plate 3 are combined and arranged; figure 1 When the umbrella-shaped expanding head shown is assembled, the sealing device 6 moves through the reserved hole of the lacing disc, and the sealing device 6 is at the junction point between the anchor bar 4 and the bearing plate 2, and its function is to seal the vapor, airflow Corrosion factors such as water flow and cement slurry are isolated from the anchor bar tunnel. The anchor bar tunnel refers to the channel through which the anchor bar 4 passes through the bearing plate 2 and enters the inner anchor head 1. The protective sleeve 5 is wrapped around the ...

Embodiment 3

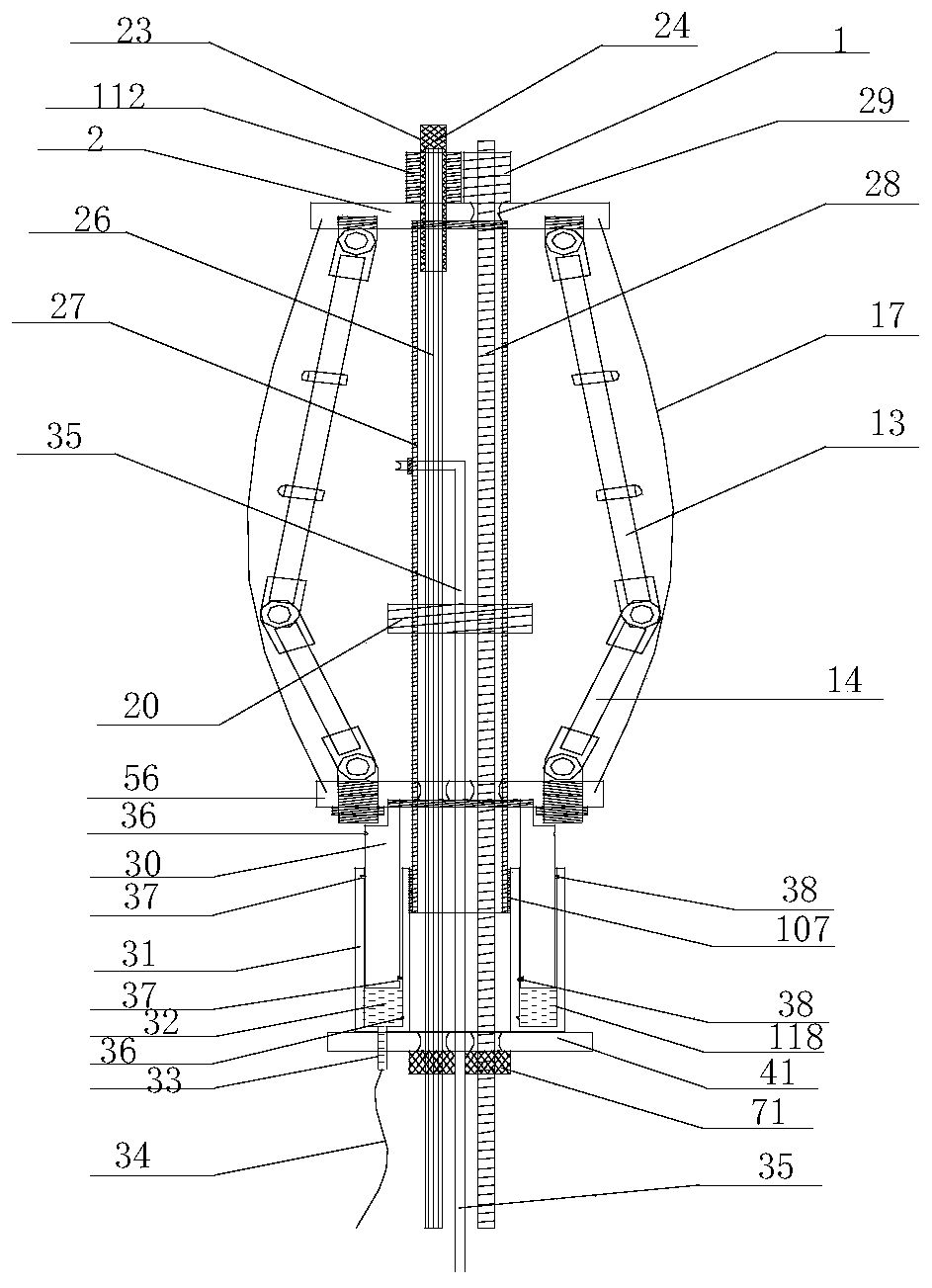

[0087] Example 3: image 3 Shown is the pre-expanding post-planting pre-retracting film bag type with a structure umbrella-shaped expanding head easy-to-cut anchor rod driven by the direct push method, and a one-way piston cylinder pre-retracting and retracting umbrella-shaped expanding device, and is equipped with a film bag The grouting pipe II adopts the central cylindrical structural member to provide the anchor bar and the grouting pipe II to pass through.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com