Trench type power transistor and manufacturing method thereof

A technology of transistors and trenches, applied in the field of power transistors and their production, can solve the problems of process variability, affecting the critical voltage of components, and unfavorable production of high-density components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. The same reference numbers in the figures denote functionally identical or similar components. Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same numerals.

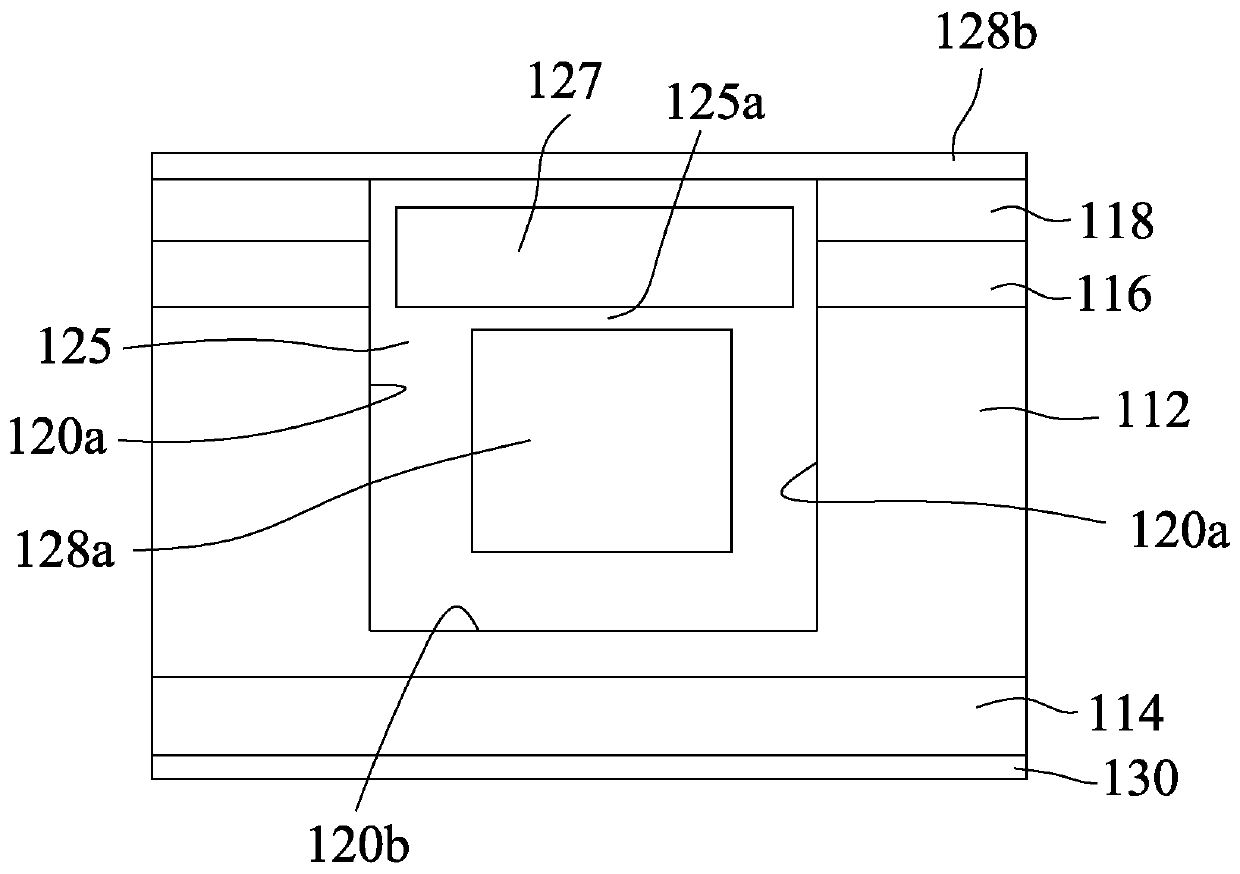

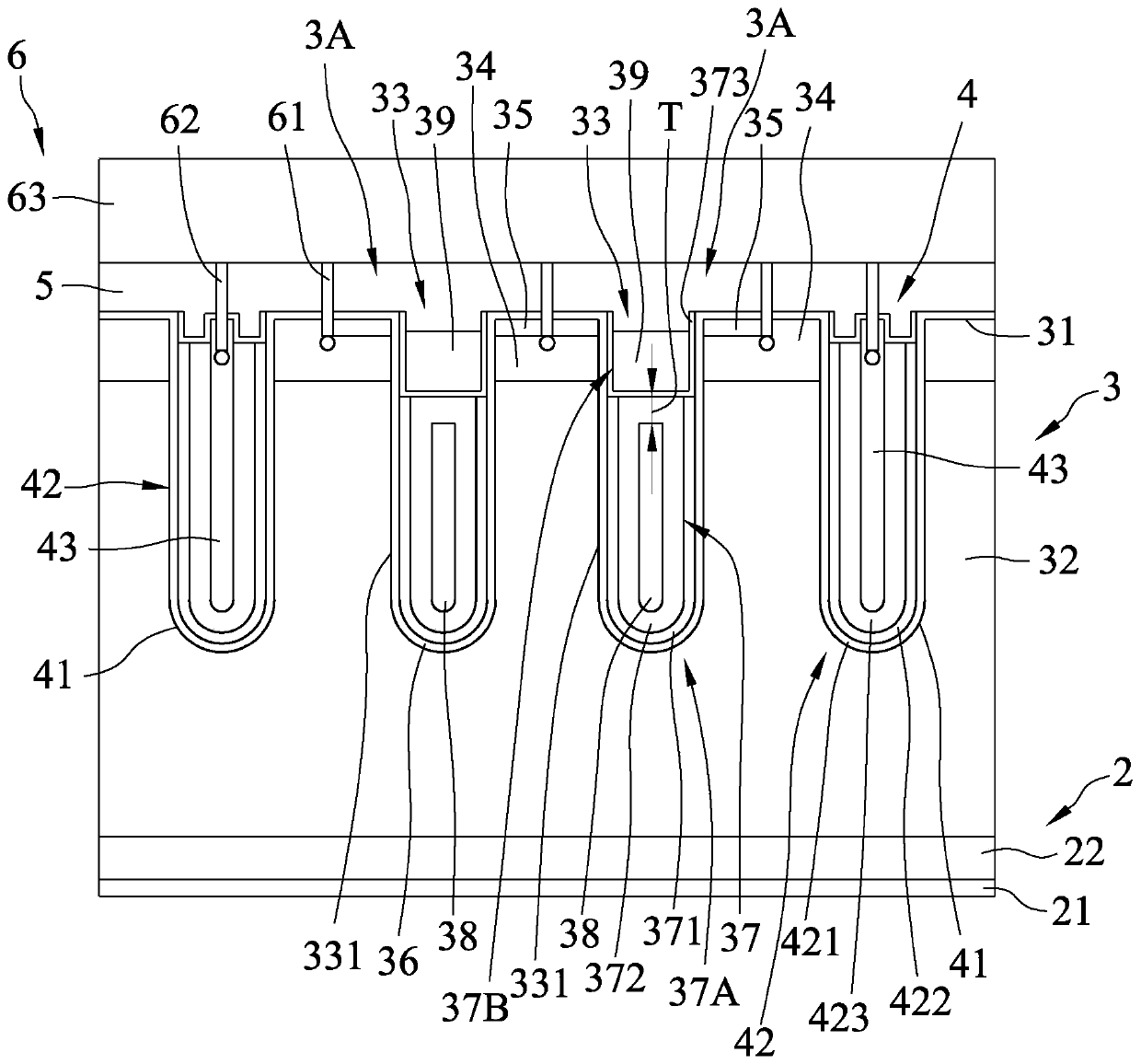

[0045] refer to figure 2 , an embodiment of the trench power transistor of the present invention includes a substrate 2 , a semiconductor base 3 , an edge termination structure 4 , an insulating layer 5 , and a conductive unit 6 .

[0046] The substrate 2 has a drain electrode 21 and a drain region 22 which is in ohmic contact with the drain electrode 21 and is made of semiconductor material and has a high concentration of doping of the first type.

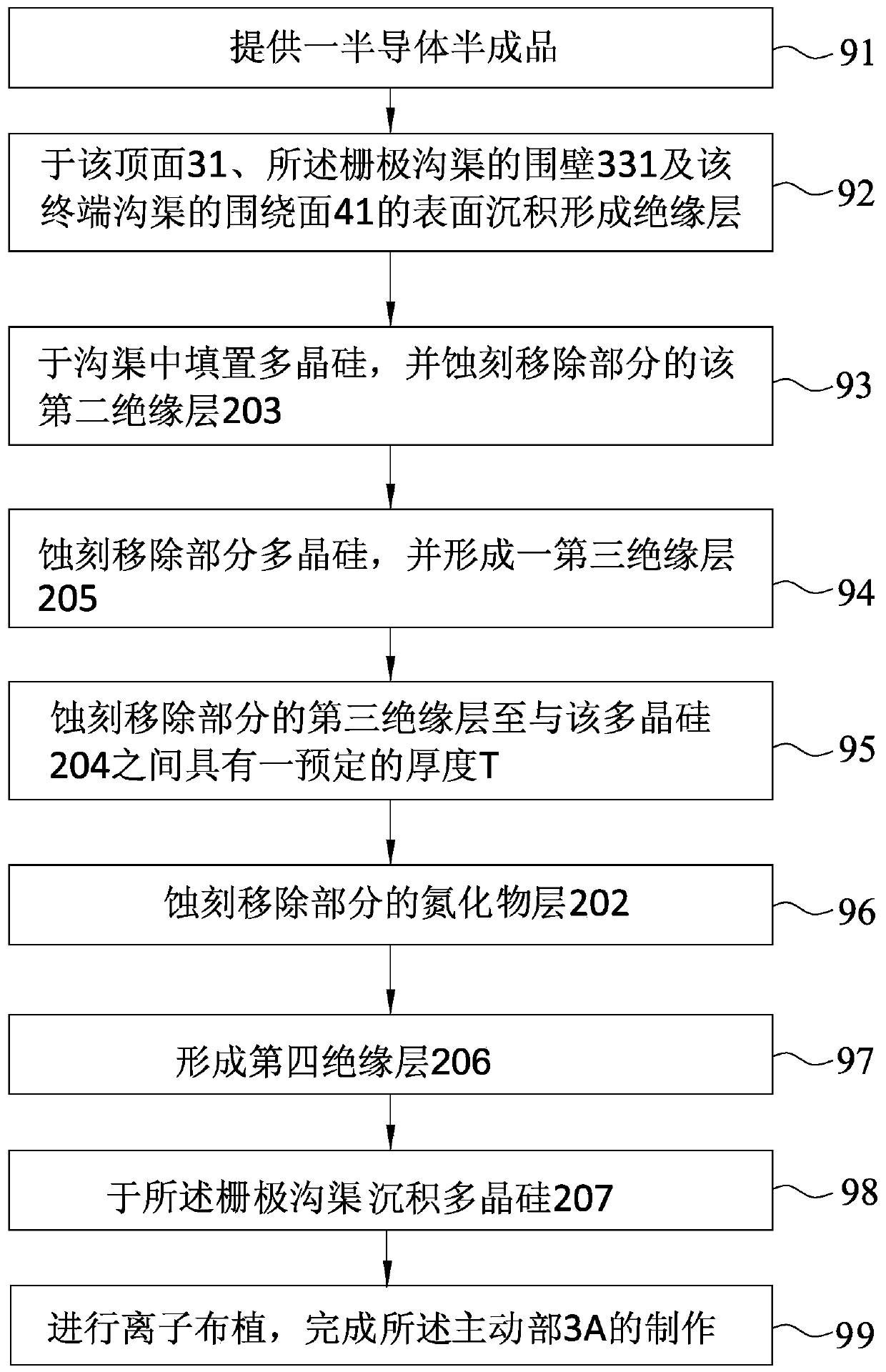

[0047] The semiconductor base 3 covers the drain region 22, has a top surface 31 opposite to the substrate 2, extends upward from the drain region 22, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com