High-heat-conduction air cooling rack of electronic equipment

A technology for electronic equipment and air-cooled machines, which is applied in the construction parts of electrical equipment, electrical components, cooling/ventilation/heating transformation, etc., which can solve the problem of limiting the range of use of air-cooling racks, increasing volume and weight, and not being able to meet the needs of aircraft space and weight requirements to achieve the effect of increasing the conduction heat dissipation area, improving adaptability and reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

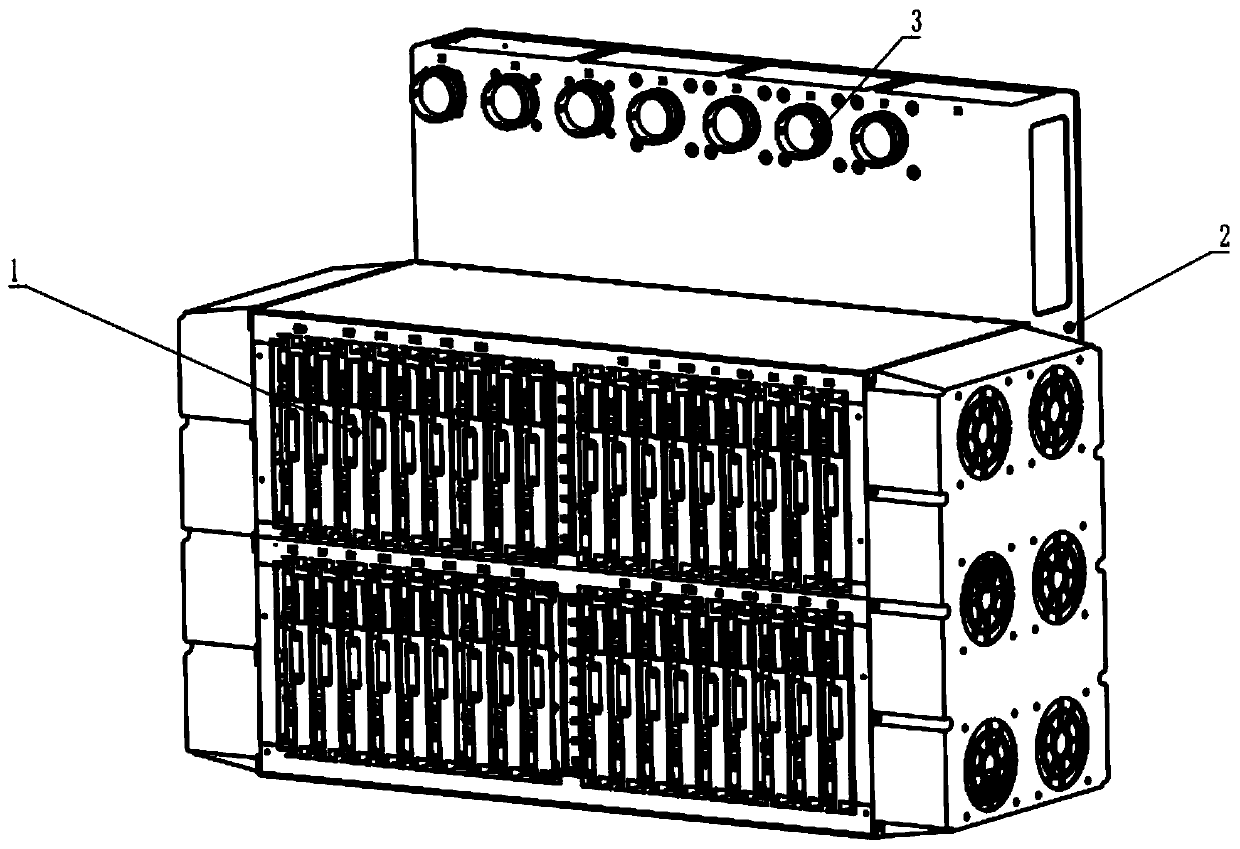

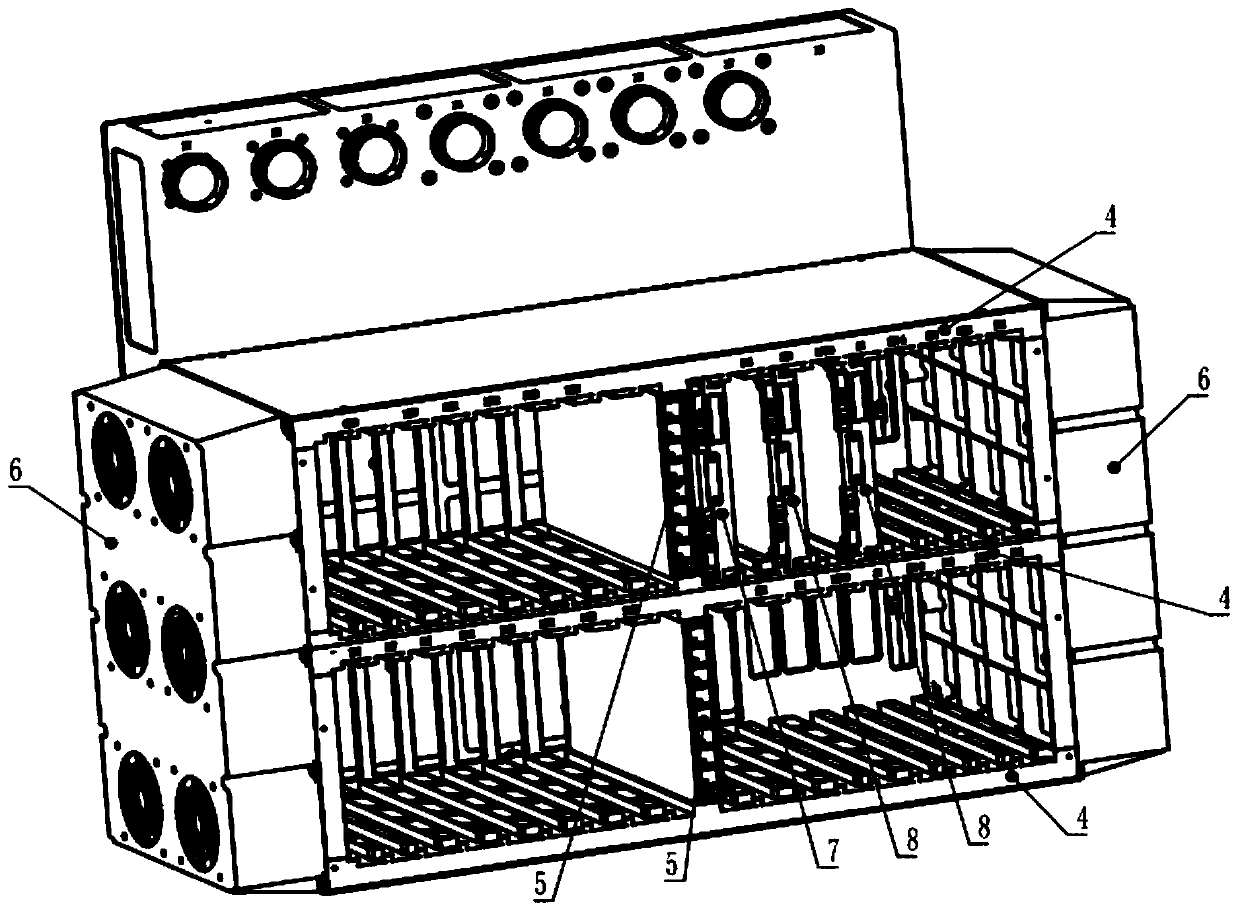

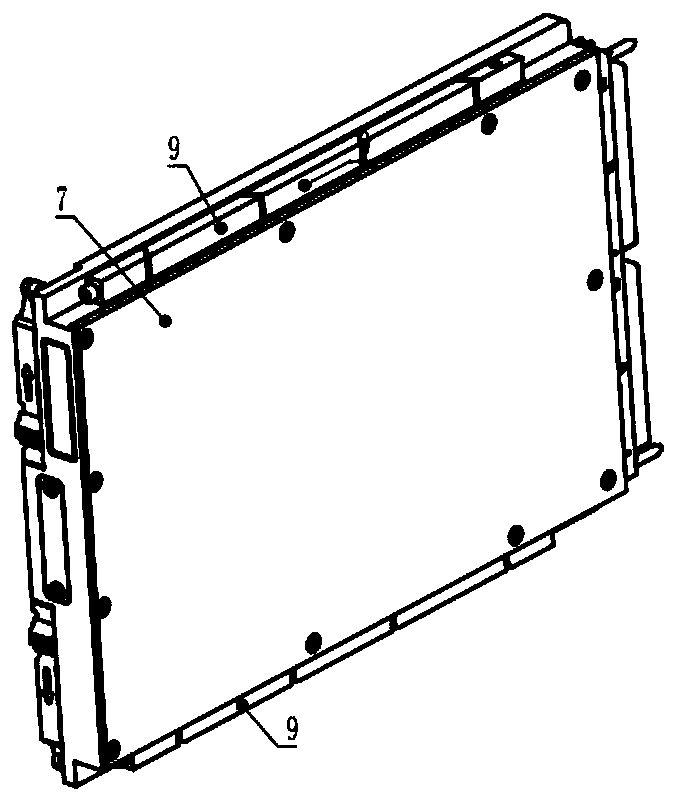

[0019] refer to Figure 1-Figure 5 . In the preferred embodiment described below, a high thermal conductivity air-cooled rack for electronic equipment includes: a rack that is divided into three functional areas: a module carrying area 1, a backplane carrying area 2, and an external interface area 3 according to different functions The structure is characterized in that: the backplane carrying area 2 is provided with external interfaces arranged in a line array, and the middle part of the module carrying area 1 in the heat-conducting air-cooled rack is provided with a movable air-cooled partition 5 connected to the upper and lower compartments, and the heat-conducting air Each module carrying area 1 in the cold rack has a high heat consumption module 7 and an ordinary air-cooled module 8 installed in the rack guide rail groove through a wedge-shaped locking strip. The side of the entire module is attached to the outer surface of the left side of the deflector 10, and the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com