Tamping assembly for a track-tamping machine

A technology of tamping machine and unit, applied in the direction of track, track superstructure, road, etc., can solve the problems of shortened life and difficult to maintain hydraulic bolt seal for a long time, and achieve the effect of reducing error proneness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

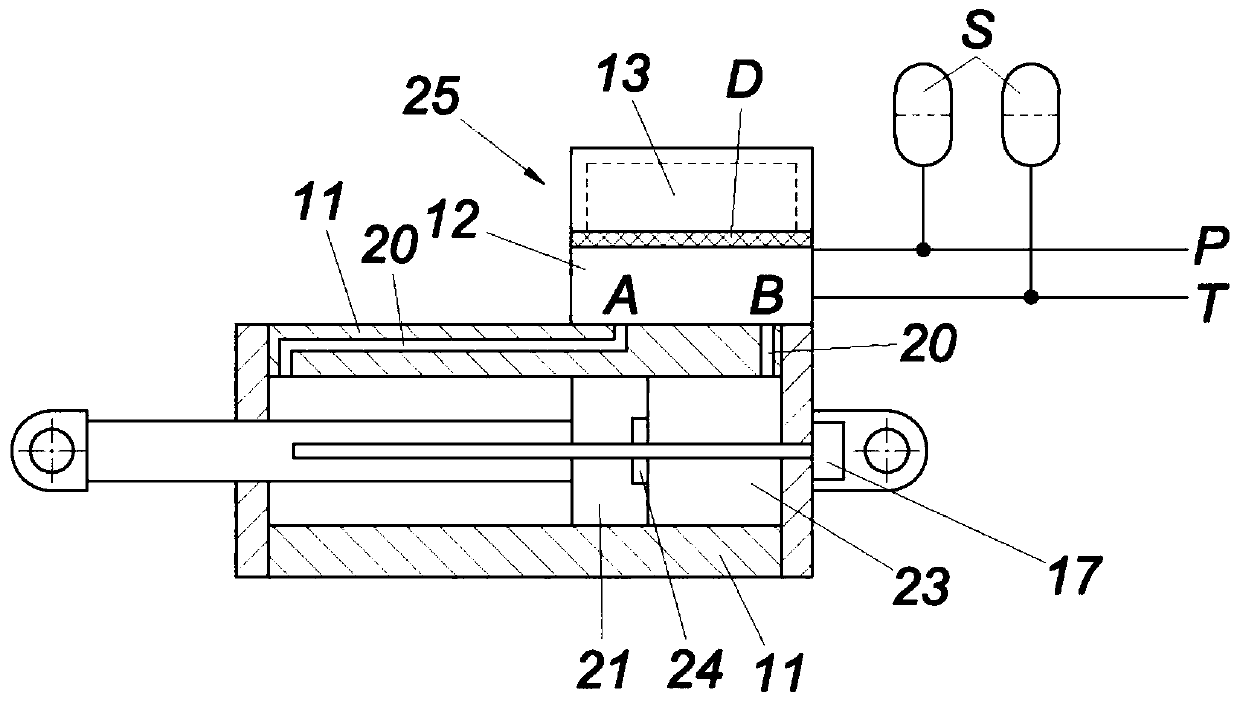

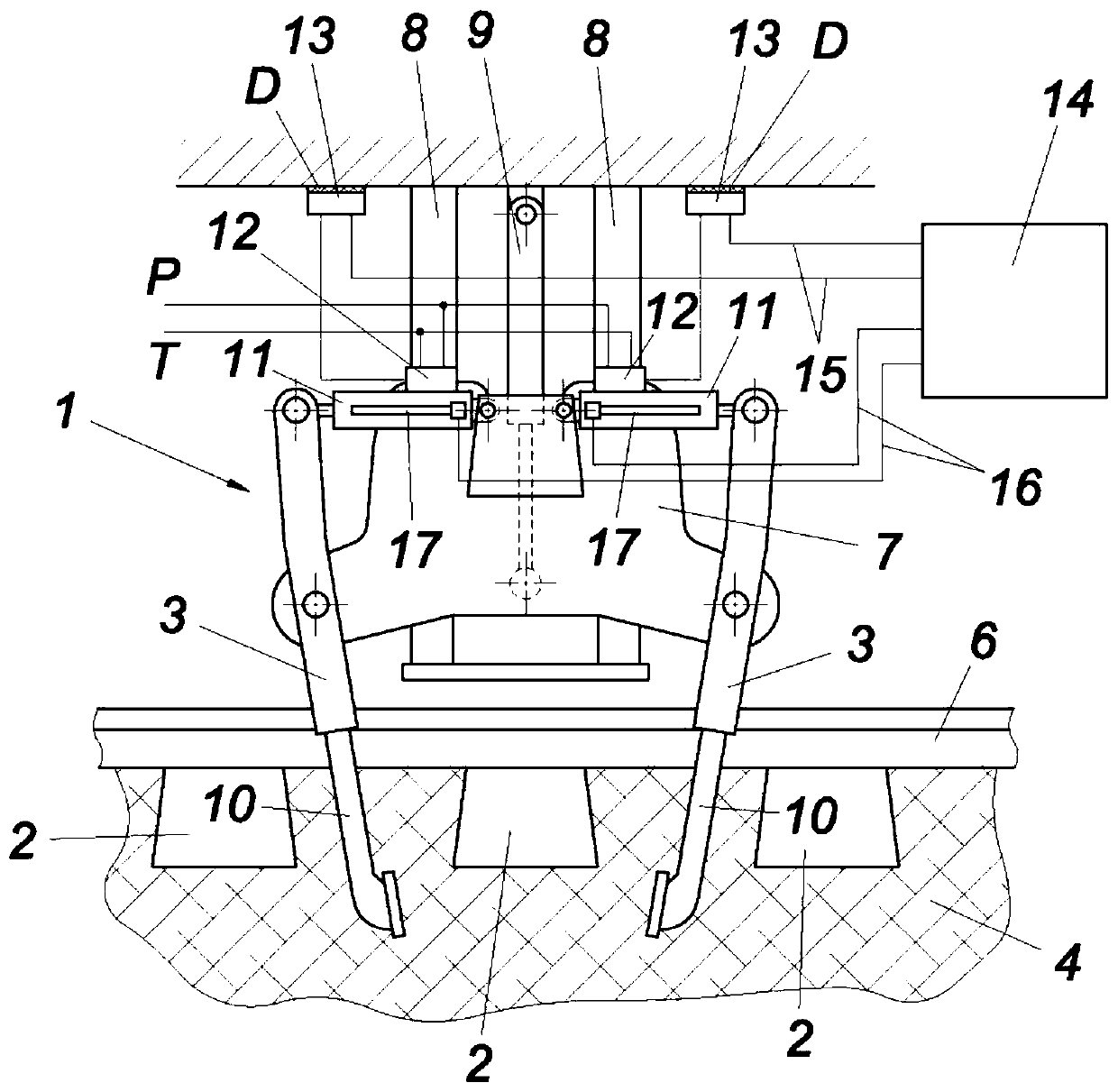

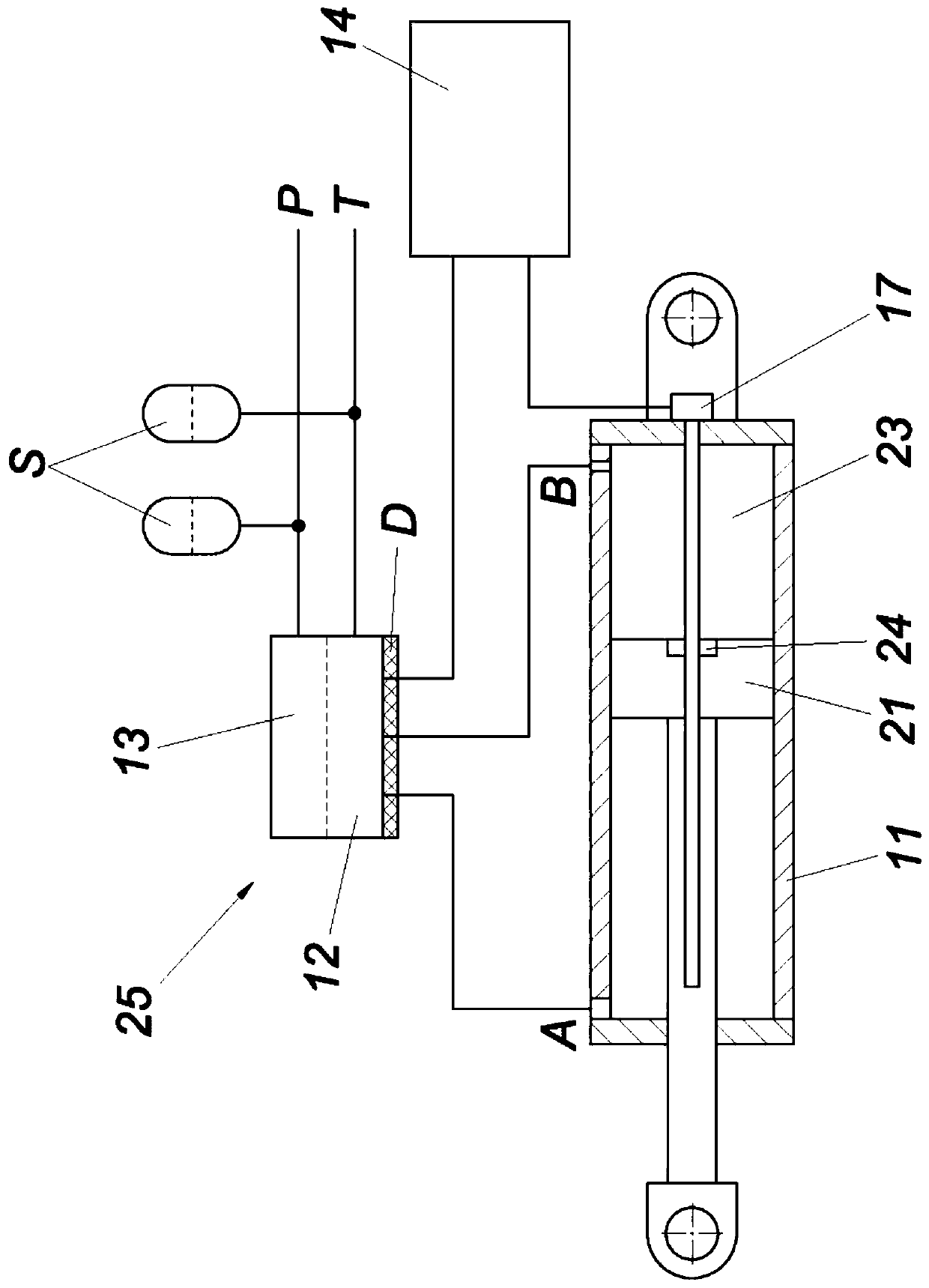

[0017] figure 1 A fully hydraulic linear tamping drive is shown. The hydraulic cylinder 11 has a bore embedded in the cylinder block, which serves as a hydraulic input 20 and is supplied directly via the ports A, B by an attached valve 25 . Hydraulic fluid under pressure from the hydraulic pump is fed into the control valve 25 via the hydraulic pressure feed line P, which is led back to the hydraulic tank via the tank return line T. As in the tank return line T, a hydraulic accumulator S is likewise arranged in the hydraulic pressure supply line P to the mechanical cylinder control valve part 12 .

[0018] A stroke sensor 17 is integrated in the hydraulic cylinder 11 . An embodiment is shown here as an inductive distance sensor, in which a position magnet 24 is provided, by means of which the deflection of the piston 21 is measured. If the cylinder chamber 23 is brought to pressure P via port B, the piston moves to the left. If the pressure loading on the piston is switche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com