Method for producing a wave spring washer for a centrifugal pendulum device, centrifugal pendulum device, clutch disc; and powertrain

A technology of centrifugal force pendulum and wave spring, applied in the direction of springs/shock absorbers, springs, manufacturing tools, etc., can solve the problem of expensive manufacturing of spring discs, and achieve the effect of effective mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

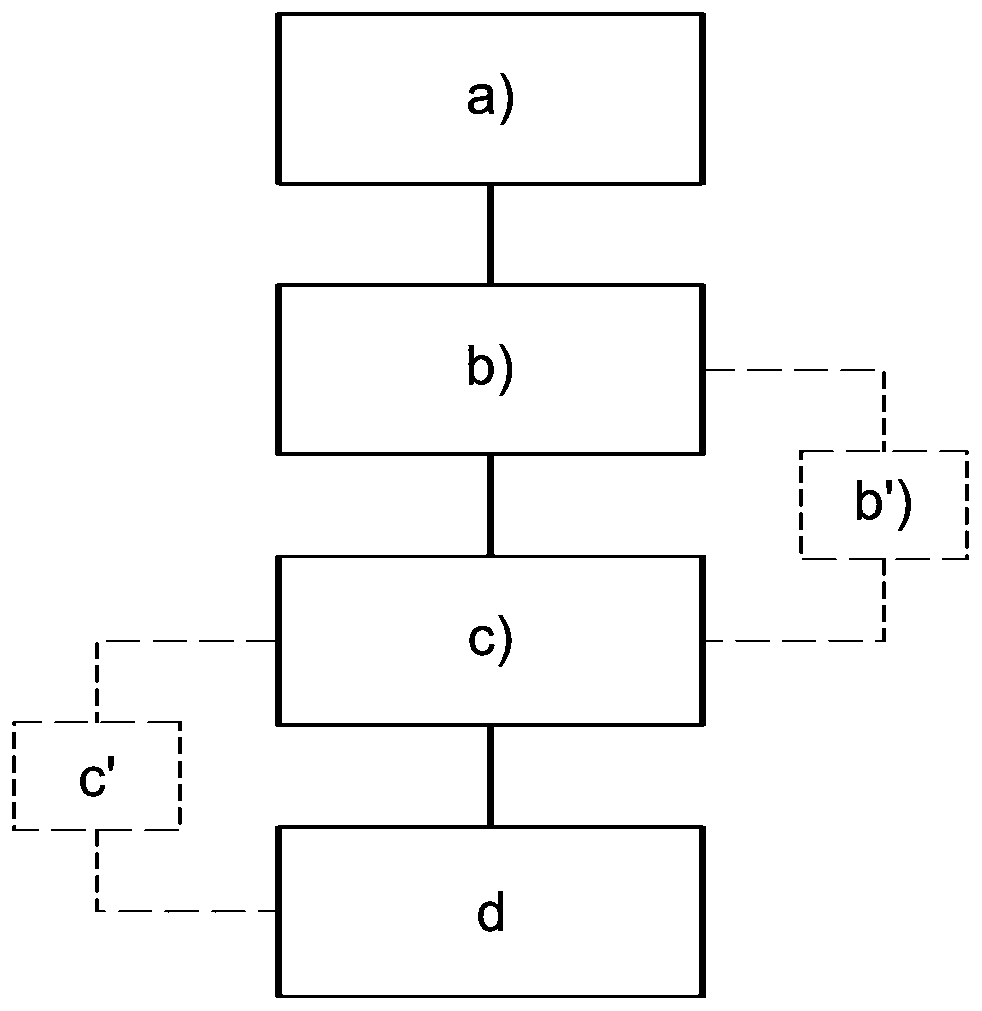

[0051] The manufacturing method for manufacturing the spring disk 7 is carried out (completely) by the following steps: a) providing the sheet material blank as a hardened sheet material ( / providing the sheet material blank from hardened metal); b) forming the annular workpiece (also called In the case of blanks), the contours 9a, 9b are punched or laser cut; c) the workpiece is cold-formed in a closed forming tool; and d) the workpiece is stress-relieving annealed.

[0052] In other words, in embodiment 1, therefore firstly a hardened sheet metal strip (sheet material blank) is provided, usually rolled up into a coil (step a)). Then (in step b) the desired contour 9a, 9b of the corrugated disk 7 is produced from the strip by means of punching in one or more strokes or by means of laser cutting. The slab is then cold-formed in a closed tool (forming tool) in one or more forming steps into a fully established corrugated disc 7 (step c)). Subsequently, stress relief annealing (...

Embodiment approach 2

[0054] The manufacturing method for manufacturing the spring disk 7 is carried out (completely) by the following steps: a) providing the sheet material blank as a hardened sheet material ( / providing the sheet material blank from hardened metal); b) forming the annular workpiece (also called stamping or laser cutting of the profiles 9a, 9b in the case of a slab); b') heating the slab to a suitable forming temperature in an oven (outside the closed forming tool) or in a closed forming tool; c ) hot forming said slab in a closed forming tool; and d) stress relief annealing the workpiece.

[0055] In other words, in embodiment 2, a hardened sheet metal strip (sheet blank) is therefore firstly provided, usually rolled up into a coil. Then (in step b)) the desired contour 9a, 9b of the corrugated disk 7 is produced from the strip by means of punching in one or more strokes or by means of laser cutting. Then (in step b')) the slab is heated in a furnace to a suitable forming tempera...

Embodiment approach 3

[0057] The manufacturing method for manufacturing the spring disk 7 is carried out (completely) by the following steps: a) providing the sheet blank as an unhardened sheet ( / providing the sheet blank from unhardened metal); The profile 9a, 9b is stamped or laser cut in the case of a slab); c) the slab is cold formed in a closed forming tool; c') the workpiece is hardened by means of a suitable hardening process; and d) stress relief annealing the workpiece.

[0058] In other words, in embodiment 3, an unhardened sheet metal strip (sheet material blank) is therefore first provided, usually rolled up into a coil. Then (in step b)) the desired contour 9a, 9b of the corrugated disk 7 is produced from the strip by means of punching in one or more strokes or by means of laser cutting. The slab is then cold-formed (in step c) in a closed tool (forming tool) in one or more forming steps into a fully established corrugated disk 7 . Next, the corrugated disk 7 is hardened (step c')) u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com