Durian-mango hazelnut kernels and a preparation method thereof

A technology for hazelnut kernels and durian, which is applied in confectionery, confectionery industry, food science and other directions, can solve the problems of high processing degree, unfavorable preservation of hazelnuts, accelerated oxidation of oil, etc., so as to maintain body health and optimize intestinal microecological balance. , to prevent the effect of accelerated oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

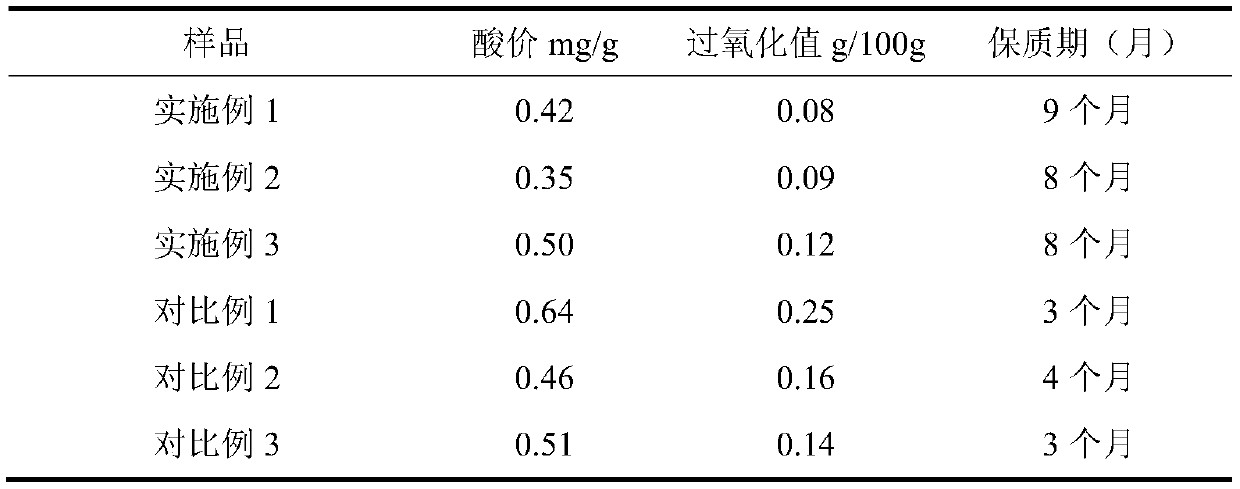

Examples

Embodiment 1

[0047] 1. Preparation of coating syrup: Take 40 parts of corn syrup, 3 parts of fructooligosaccharide (liquid), 0.5 part of edible salt, 2 parts of whole milk powder, and 15 parts of purified water. Heating at 70°C, fully stirring evenly, so that the coating syrup forms a uniform fluid liquid state. Prepare a large amount of coating syrup according to this ratio and cool it for later use.

[0048] 2. The first step of coating and baking the hazelnut kernels: take 100 parts of uncoated raw material hazelnut kernels, 5 parts of the coating syrup prepared in step 1, and 14 parts of cornstarch. The first step of coating the hazelnut kernels is completed in the coating machine, and the cornstarch is evenly wrapped on the surface of the hazelnut kernels. When coating, pay attention to the order of adding coating syrup and cornstarch, first add an appropriate amount of coating syrup, and when the syrup is evenly attached to the surface of the hazelnuts, sprinkle cornstarch evenly, a...

Embodiment 2

[0053] 1. Preparation of coating syrup: Take 43 parts of corn syrup, 3.4 parts of fructooligosaccharide (liquid), 0.5 part of edible salt, 3 parts of whole milk powder, and 16 parts of purified water. Heating at 80°C, fully stirring evenly, so that the coating syrup forms a uniform fluid liquid state. Prepare a large amount of coating syrup according to this ratio and cool it for later use.

[0054] 2. The first step of coating and baking the hazelnut kernels: take 100 parts of uncoated hazelnut kernels, 7 parts of the coating syrup prepared in step 1, and 19 parts of cornstarch. The first step of coating the hazelnut kernels is completed in the coating machine, and the cornstarch is evenly wrapped on the surface of the hazelnut kernels. When coating, pay attention to the order of adding coating syrup and cornstarch, first add an appropriate amount of coating syrup, and when the syrup is evenly attached to the surface of the hazelnuts, sprinkle cornstarch evenly, and when the...

Embodiment 3

[0059] 1. Preparation of coating syrup: Take 40 parts of corn syrup, 3 parts of fructooligosaccharide (liquid), 0.5 part of edible salt, 2 parts of whole milk powder, and 15 parts of purified water. Heating at 75°C, fully stirring evenly, so that the coating syrup forms a uniform fluidity liquid state. Prepare a large amount of coating syrup according to this ratio and cool it for later use.

[0060] 2. The first step of coating and baking the hazelnut kernels: take 100 parts of uncoated raw material hazelnut kernels, 5 parts of the coating syrup prepared in step 1, and 14 parts of cornstarch. The first step of coating the hazelnut kernels is completed in the coating machine, and the cornstarch is evenly wrapped on the surface of the hazelnut kernels. When coating, pay attention to the order of adding coating syrup and cornstarch, first add an appropriate amount of coating syrup, and when the syrup is evenly attached to the surface of the hazelnuts, sprinkle cornstarch evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com