Extraction method of polygonatum odoratum polysaccharide and polygonatum odoratum polysaccharide extractive

An extraction method, Polygonatum polysaccharide technology, applied in the field of Polygonatum polysaccharide extraction, Polygonatum polysaccharide extract, can solve the problems of low extraction rate, high liquid material, high energy consumption, etc., achieve low extraction cost, good purity, The effect of high nutritional and health value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

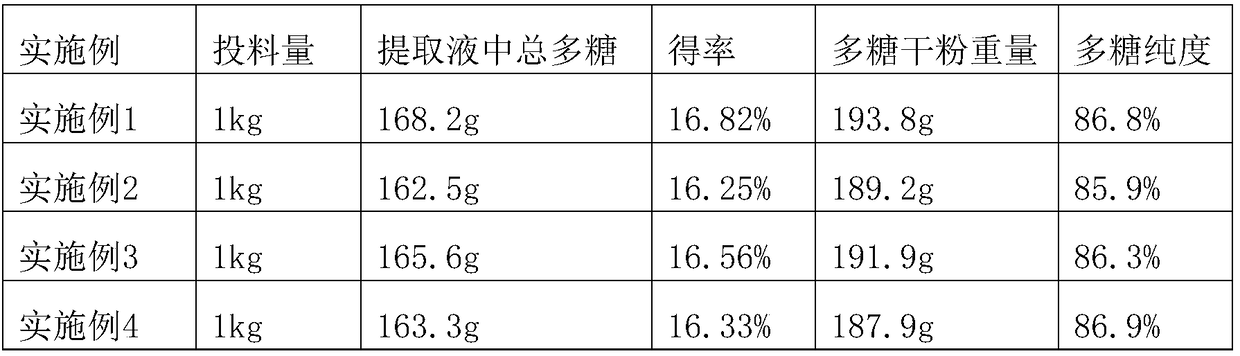

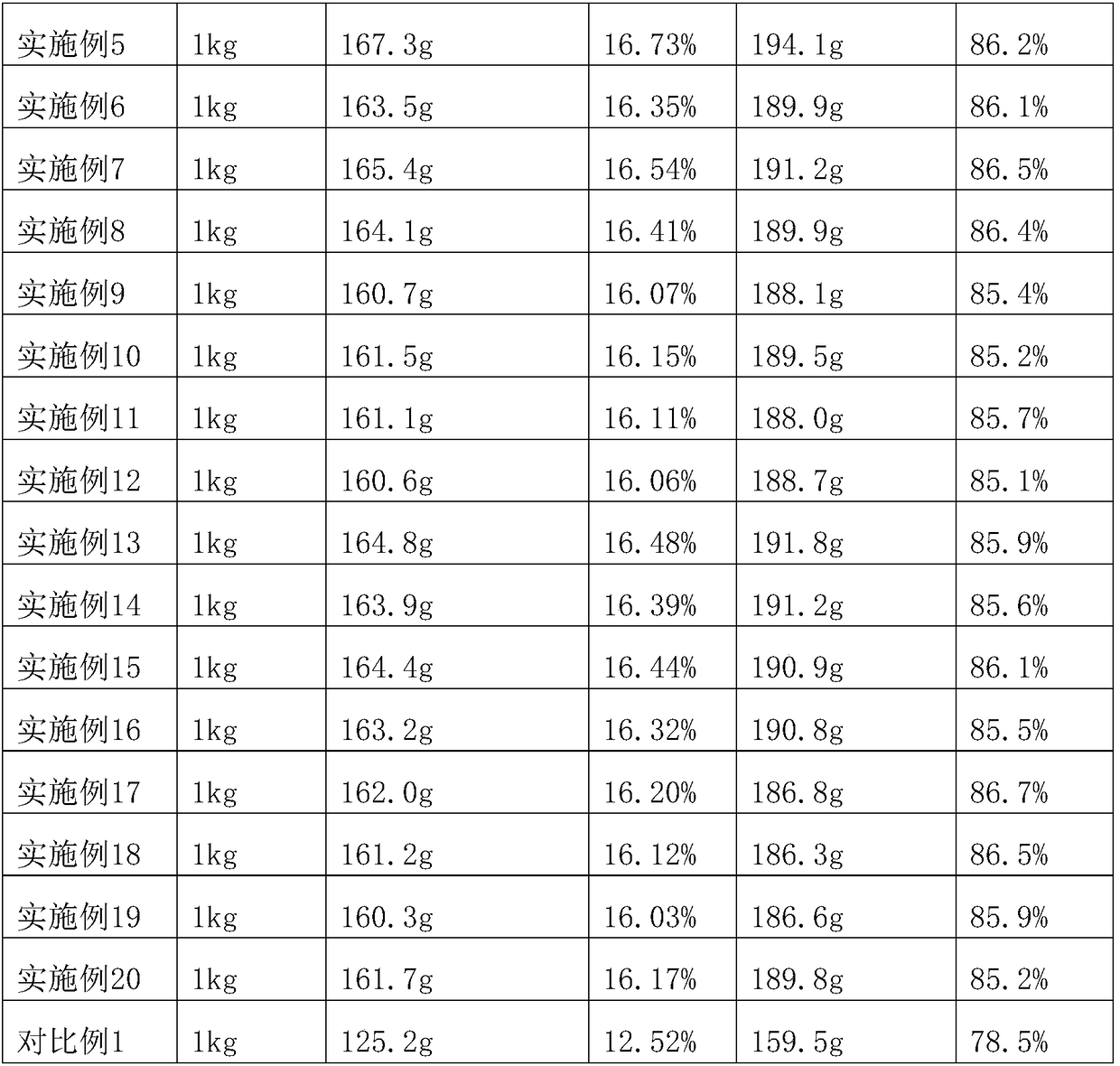

Examples

Embodiment 1

[0032] A method for extracting polygonatum polysaccharide, said method comprising the following steps:

[0033] 1) Take the Polygonatum Polygonatum raw material, grind it into coarse powder, add water and enzyme to mix evenly, keep the temperature at 40°C, and perform an enzymatic hydrolysis reaction for 2 hours, wherein the amount of water added is 8 times the mass of Polygonatum Polygonatum, and the addition of the enzyme The amount is 0.3% of Polygonatum Polygonatum mass, and the enzymes are cellulase, pectinase and hemicellulase, and the mass ratio of the cellulase, pectinase and hemicellulase is 2:1:1.

[0034] 2) The temperature of the enzymolysis solution was raised to 90° C., stirred and extracted for 1 hour, centrifuged, and the supernatant was taken.

[0035] 3) Continue to add process water with a material ratio of 1:8 to the filter cake, raise the temperature to 90°C, stir and extract for 1 hour. Centrifuge, take the supernatant, and repeat the above steps once mo...

Embodiment 2

[0039] A method for extracting polygonatum polysaccharide, said method comprising the following steps:

[0040] 1) Take the Polygonatum Polygonatum raw material, grind it into coarse powder, add water and enzyme to mix evenly, keep the temperature at 40°C, and perform an enzymatic hydrolysis reaction for 2 hours, wherein the amount of water added is 8 times the mass of Polygonatum Polygonatum, and the addition of the enzyme The amount is 0.4% of Polygonatum Polygonatum quality, and described enzyme is cellulase, pectinase, protease, and the mass ratio of described cellulase, pectinase and protease is 2:2:1.

[0041] 2) The temperature of the enzymolysis solution was raised to 90° C., stirred and extracted for 1 hour, centrifuged, and the supernatant was taken.

[0042] 3) Continue to add process water with a material ratio of 1:8 to the filter cake, raise the temperature to 90°C, stir and extract for 1 hour. Centrifuge, take the supernatant, and repeat the above steps once mo...

Embodiment 3

[0046] A method for extracting polygonatum polysaccharide, said method comprising the following steps:

[0047] 1) Take the Polygonatum Polygonatum raw material, grind it into coarse powder, add water and enzyme to mix evenly, keep the temperature at 40°C, and perform an enzymatic hydrolysis reaction for 2 hours, wherein the amount of water added is 8 times the mass of Polygonatum Polygonatum, and the addition of the enzyme The amount is 0.2% of Polygonatum Polygonatum mass, the enzymes are cellulase and protease, and the mass ratio of cellulase and protease is 3:1.

[0048] 2) The temperature of the enzymolysis solution was raised to 90° C., stirred and extracted for 1 hour, centrifuged, and the supernatant was taken.

[0049] 3) Continue to add process water with a material ratio of 1:8 to the filter cake, raise the temperature to 90°C, stir and extract for 1 hour. Centrifuge, take the supernatant, and repeat the above steps once more for the obtained filter cake.

[0050] 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com