Electronic element, plastic coating technology of microswitch with resistor and microswitch with resistor

A technology of electronic components and micro switches, which is applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of poor practical applicability, increased production costs, and reduced service life, so as to improve quality stability, increase production yield, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

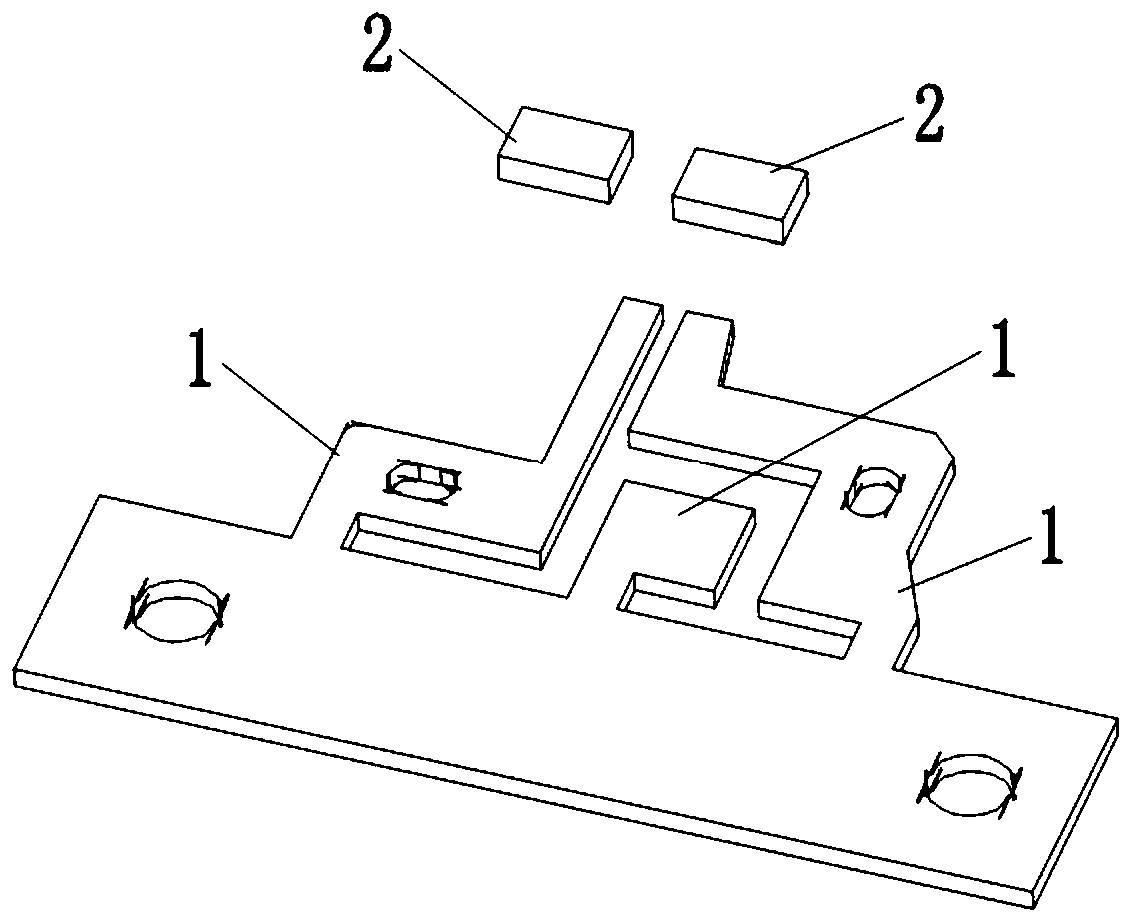

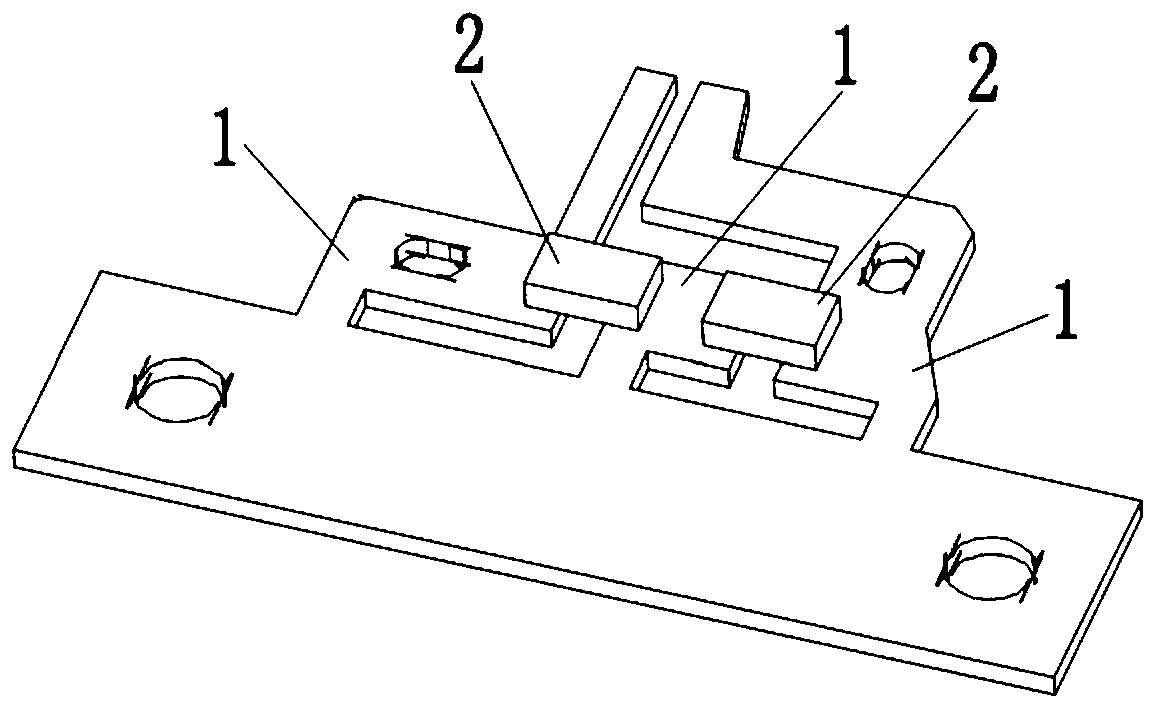

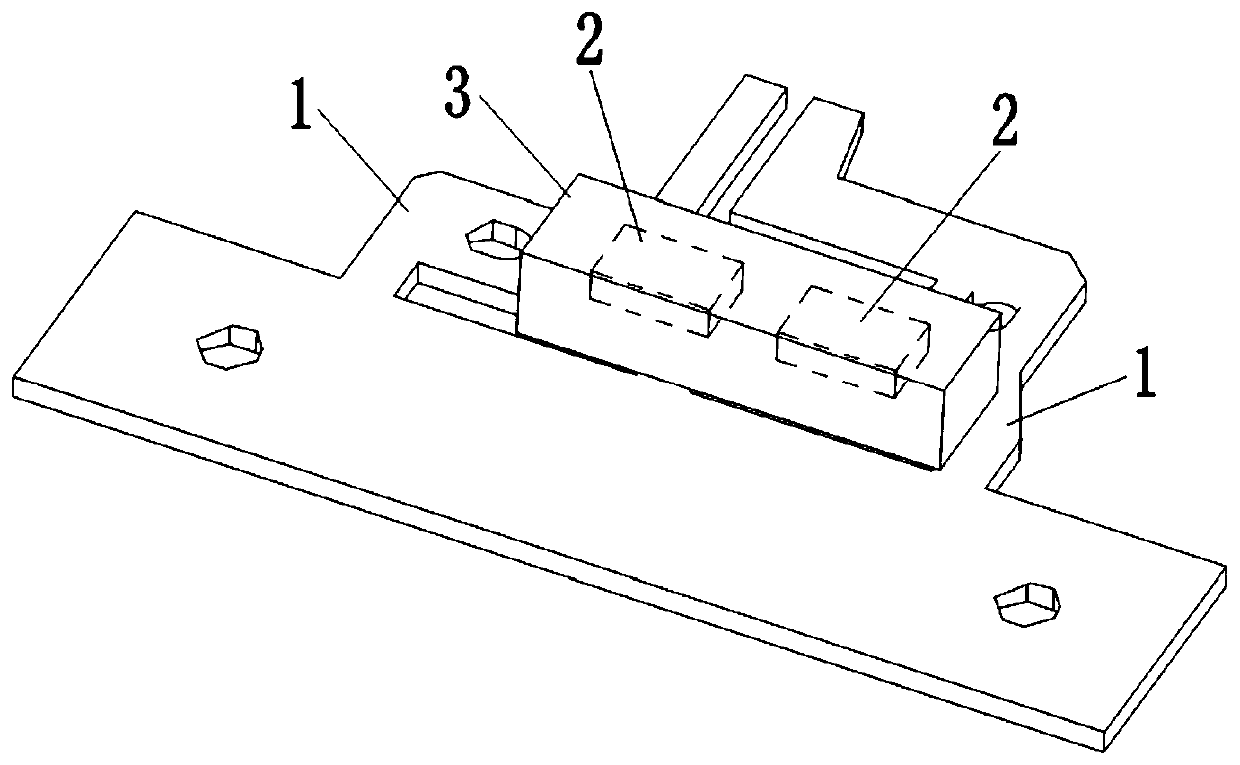

[0068] Preparation of a resistive microswitch, wherein the assembly assembly of a resistive microswitch see figure 1 and figure 2 As shown, the preparation process is based on the above-mentioned overmolding process of the microswitch with resistance. Table 1 shows the overmolding process parameters of the resistive microswitches of Examples 1 to 4 and the properties of the prepared resistive microswitches.

[0069] The overmolding process parameters of the band resistance micro switch of table 1 embodiment 1~4 and the performance of the band resistance micro switch prepared

[0070]

[0071] As can be seen from Table 1, qualified microswitches with resistance can be produced by the double-layer overmolding process of the present invention. Moreover, through the low-temperature and low-voltage plastic-coated protection resistor and the connection relationship between the resistor and the terminal in advance, it can effectively keep the resistor from shifting or falling o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com