Automatic die opening and closing and cleaning device for thermoset composite die-pressing die

A composite material, automatic opening and closing technology, applied in the direction of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of high labor intensity and low efficiency, and achieve reduced labor intensity, high integration and improvement The effect of the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0147] Embodiment 1, no product mold execution process:

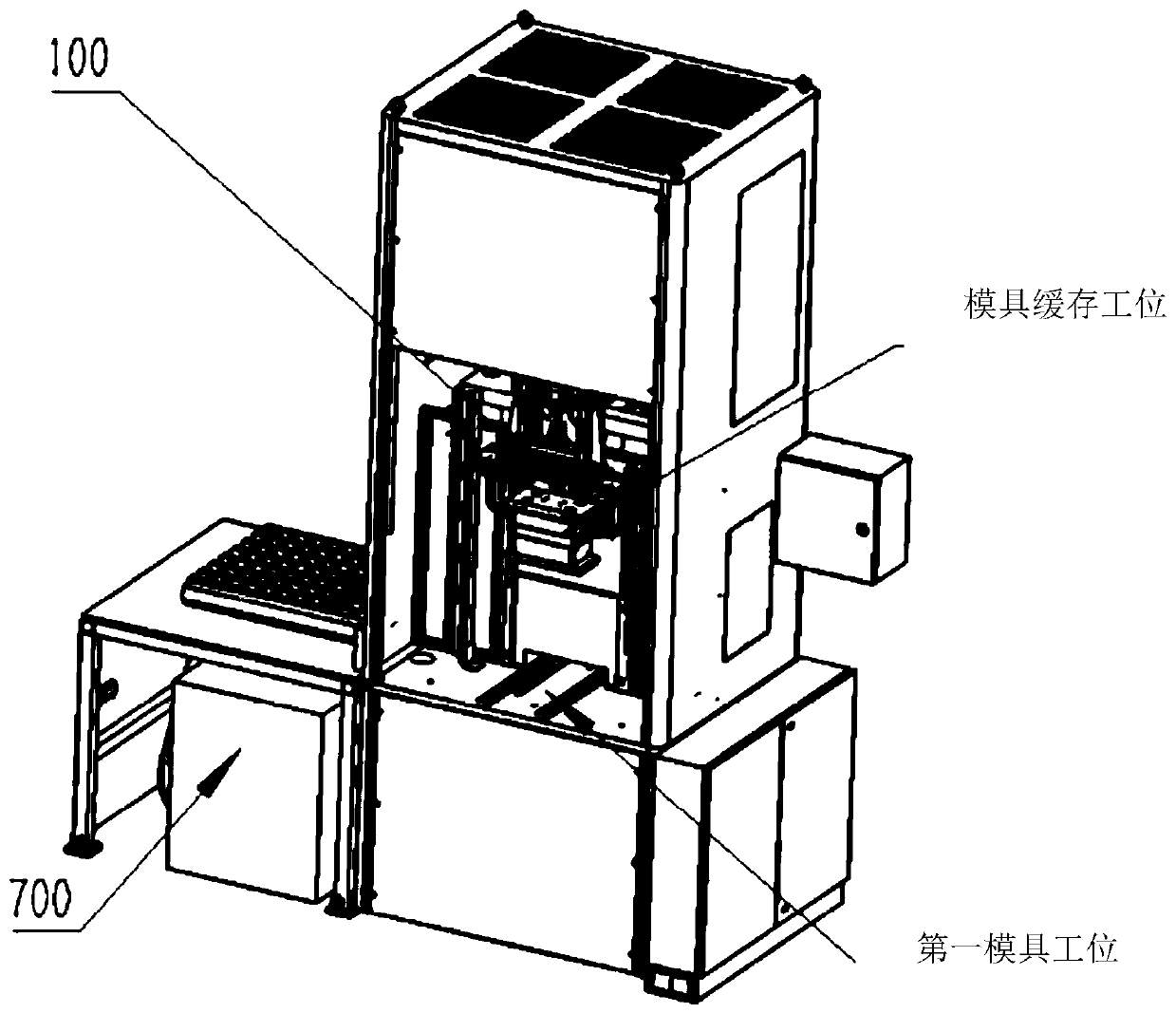

[0148] (1) The mold transport robot transports the mold 1 to the waiting position (the first mold station) next to the mold opening machine and waits, and sends a signal 1 to the mold opening machine.

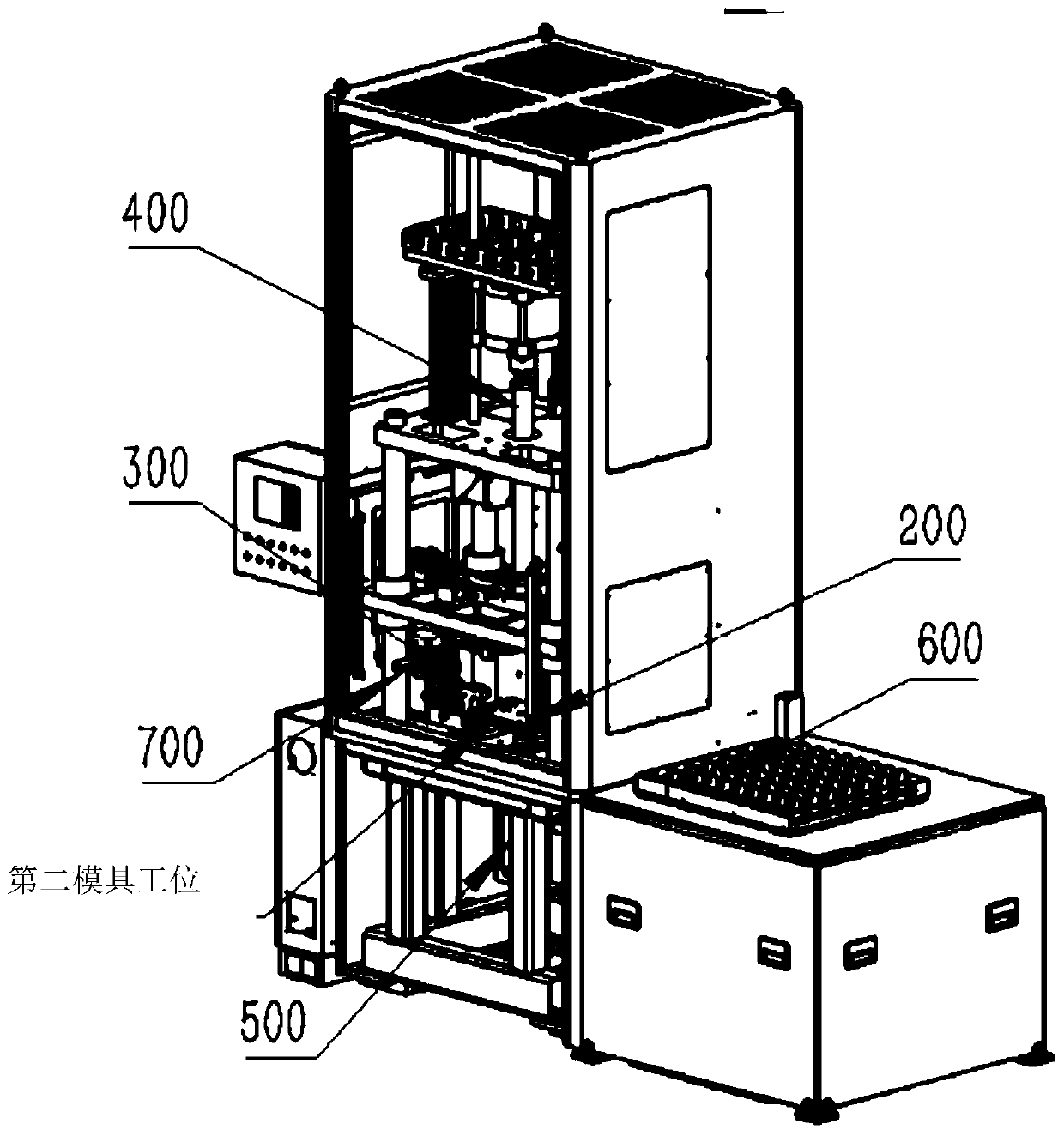

[0149] (2) After the mold opening machine meets the production conditions, it is adjusted to the automatic state. After clicking the run button, the rear lift door 711 rises, and the mold sliding table 200 moves to the mold receiving position (that is, the robot waiting position next to the mold opening machine, which is also the first mold station).

[0150] (3) The mold transport robot releases the jaws, and places the mold 1 on the mold slide 200 .

[0151] (4) Manually give the mold transport robot a signal (i.e. click the run button again), the mold slide table 200 returns to the mold opening position (ie the second mold station of the present invention), the mold transport robot moves to the mold preheating statio...

Embodiment 2

[0169] The mold opening process when embodiment 2. product is housed:

[0170] (1) The mold sliding table 200 moves to the mold opening position, and the rear lifting door 702 descends to the position.

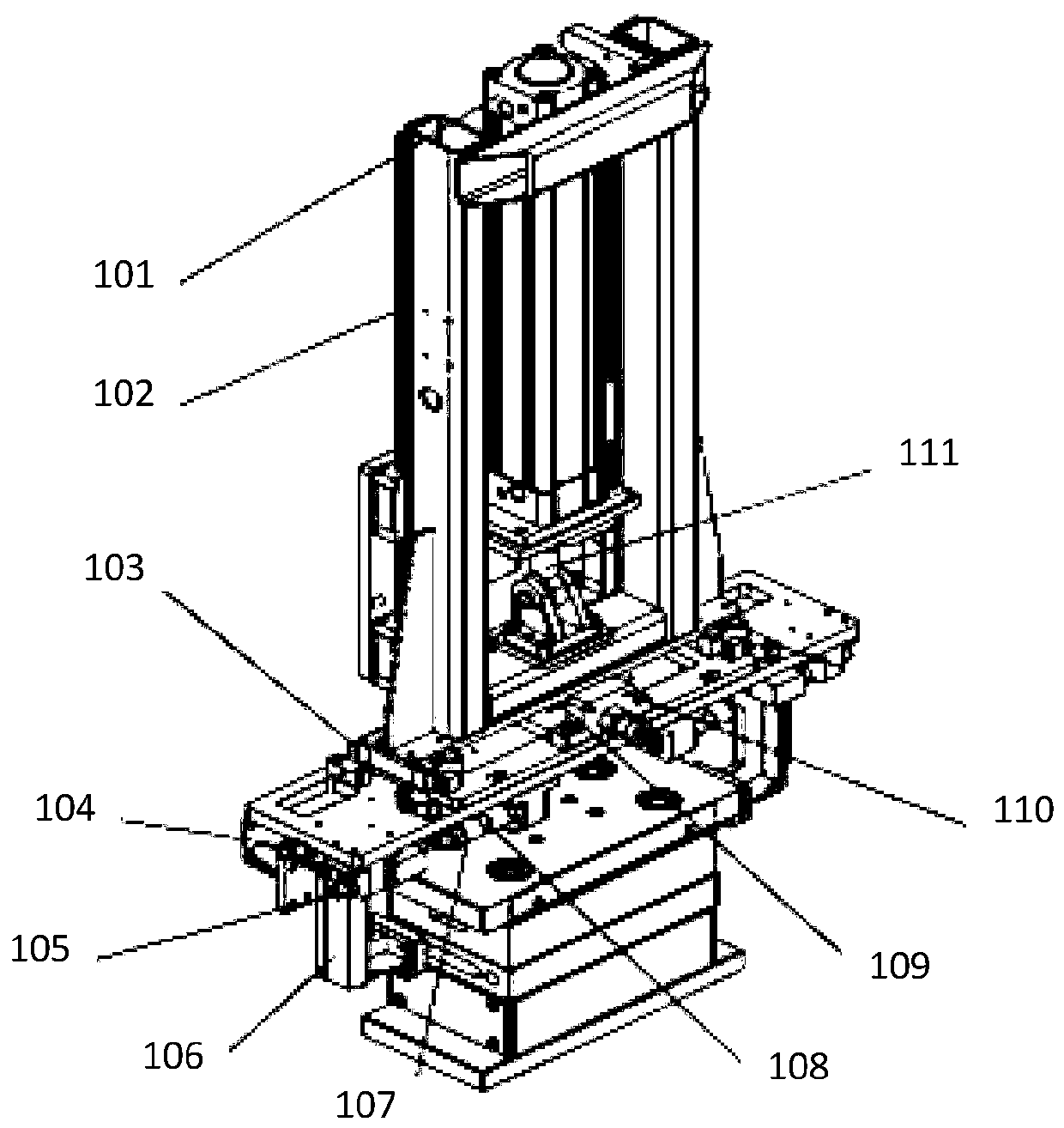

[0171] (2) The large mold opening cylinder 405 and the mold opening frame lifting cylinder 404 move simultaneously to lower the upper mold fixing plate 401 to the mold opening position.

[0172] (3) The upper mold clamping device and the lower mold clamping device clamp the mold.

[0173] (4) After the large mold opening cylinder 405 moves in place first, the mold opening frame lifting cylinder 404 moves again, and the upper mold fixing plate 401 is raised in place.

[0174] (5) The ejection cylinder 501 is stretched out, and the product is ejected out of the mold.

[0175] (6) The front lift gate 711 rises, the workman takes out the product and cleans up the mould, and the falling stop bar 705 swings into place.

[0176] (7) After the front lifting door 711 is lowered into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com