Adaptive electrode wall surface micro-nano pit micro-bubble generating device and manufacturing method thereof

A micro-bubble generation and self-adaptive technology, applied in transportation and packaging, ship hull, ship construction, etc., can solve the problem of difficulty in controlling the size of micro-bubbles, failure to achieve self-adaptive control of micro-bubbles, and the influence of micro-bubble drag reduction rate and other problems, to achieve stable and lasting drag reduction effect, realize drag reduction effect, and enhance the effect of sustainability and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

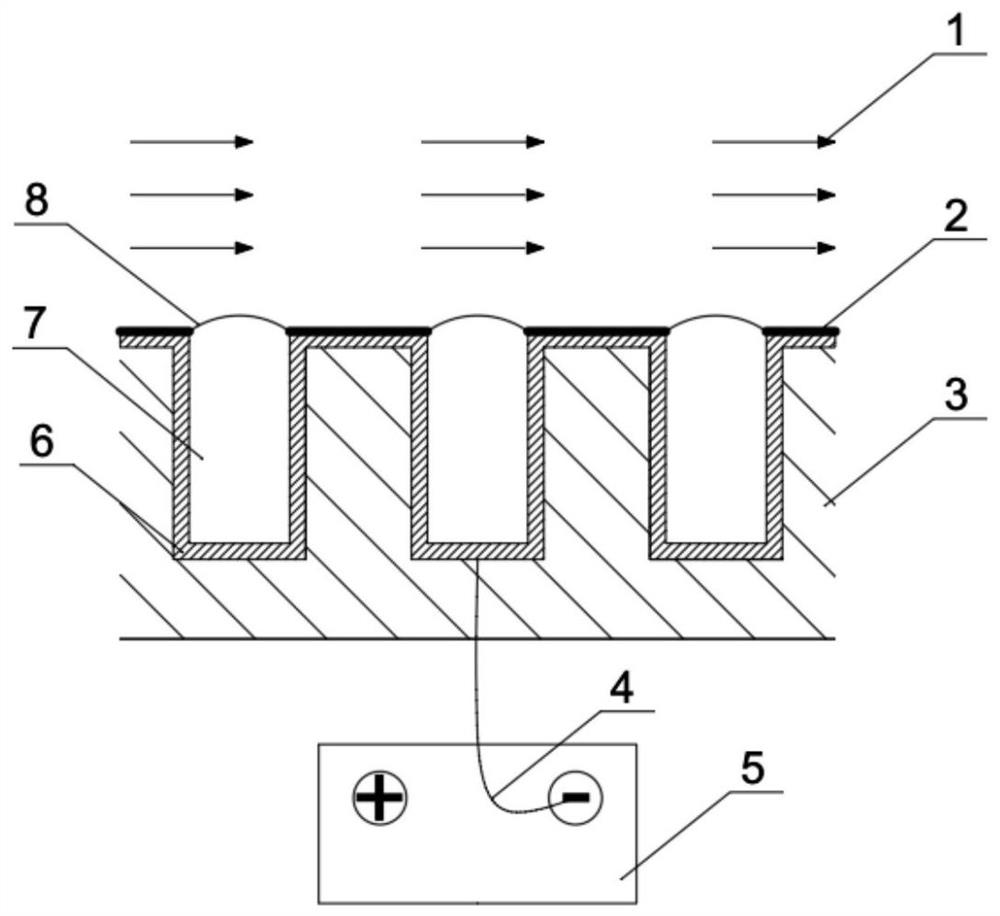

[0034] Such as figure 1 As shown, in this embodiment, the micro-nano pit and micro-bubble generating device on the wall of the self-adaptive electrode includes a substrate 3 and a DC power supply 5;

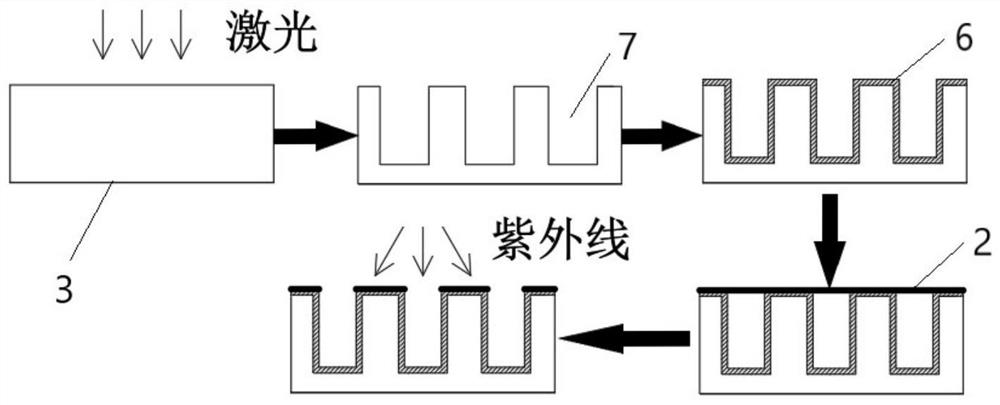

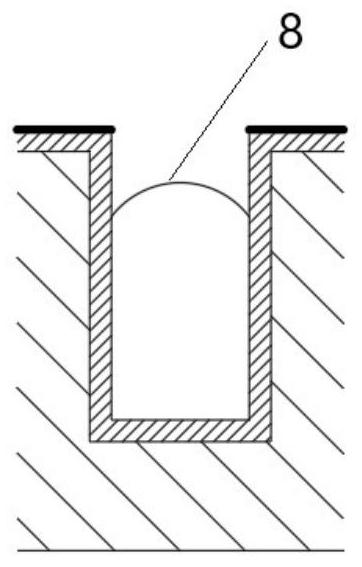

[0035] The substrate 3 is made of plexiglass material or a silicon wafer, and cylindrical micro-nano pits 7 on the electrode wall are evenly distributed on the surface of the substrate 3. The diameter of the micro-nano pits 7 on the electrode wall is 40-100 μm, and the depth is 20-150 μm. ;

[0036] The walls of the micro-nano pits 7 on the electrode wall and the upper surface of the substrate 3 are all provided with a sputtered metal layer, and the metal of the sputtered metal layer is gold, thereby form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com