Automatic arrangement take-up machine

A wire take-up, automatic technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of labor difficulties, affecting quality, inaccurate adjustment, etc., to avoid poor elongation and strength. , Improve work efficiency, evenly arrange the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

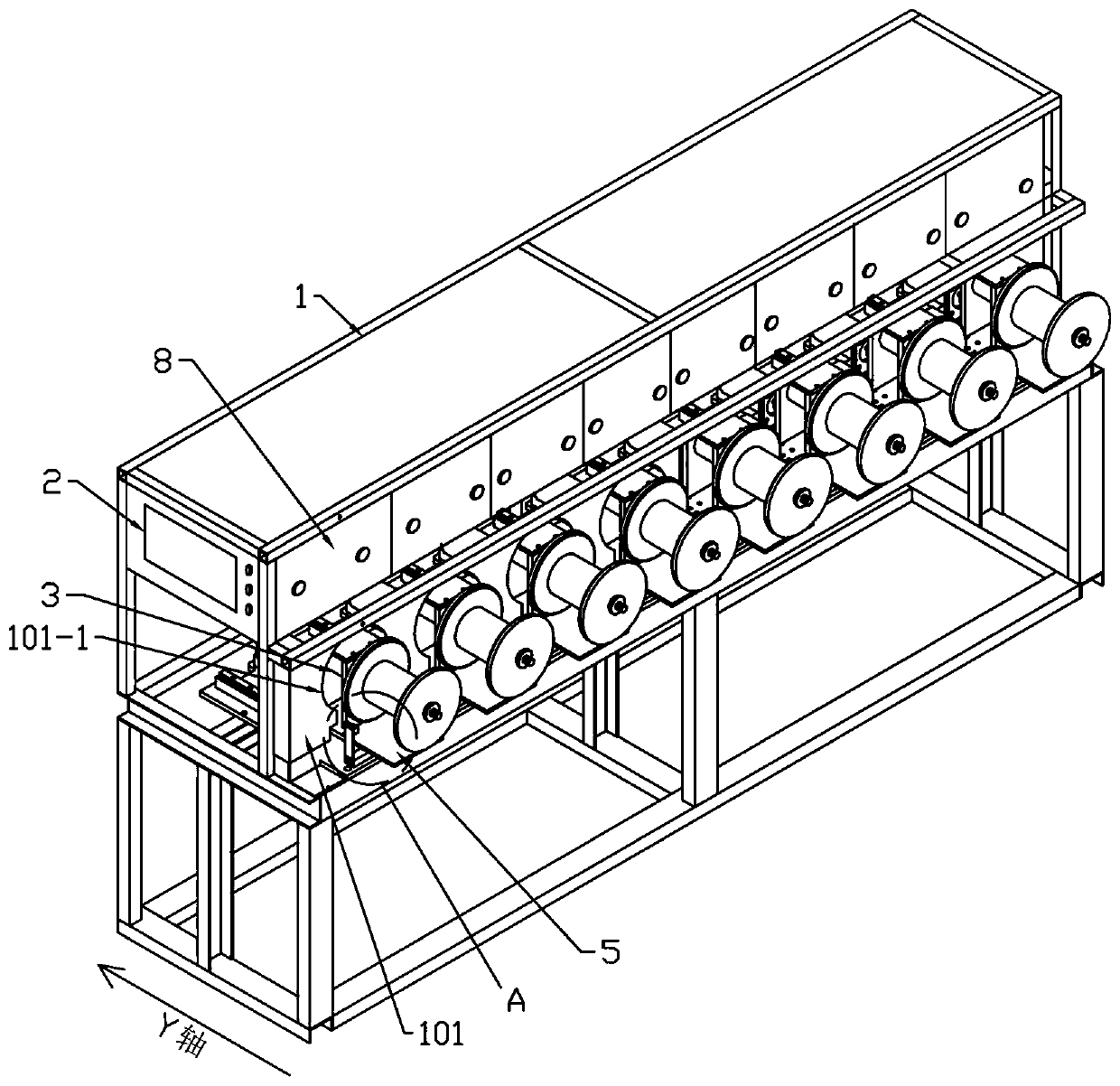

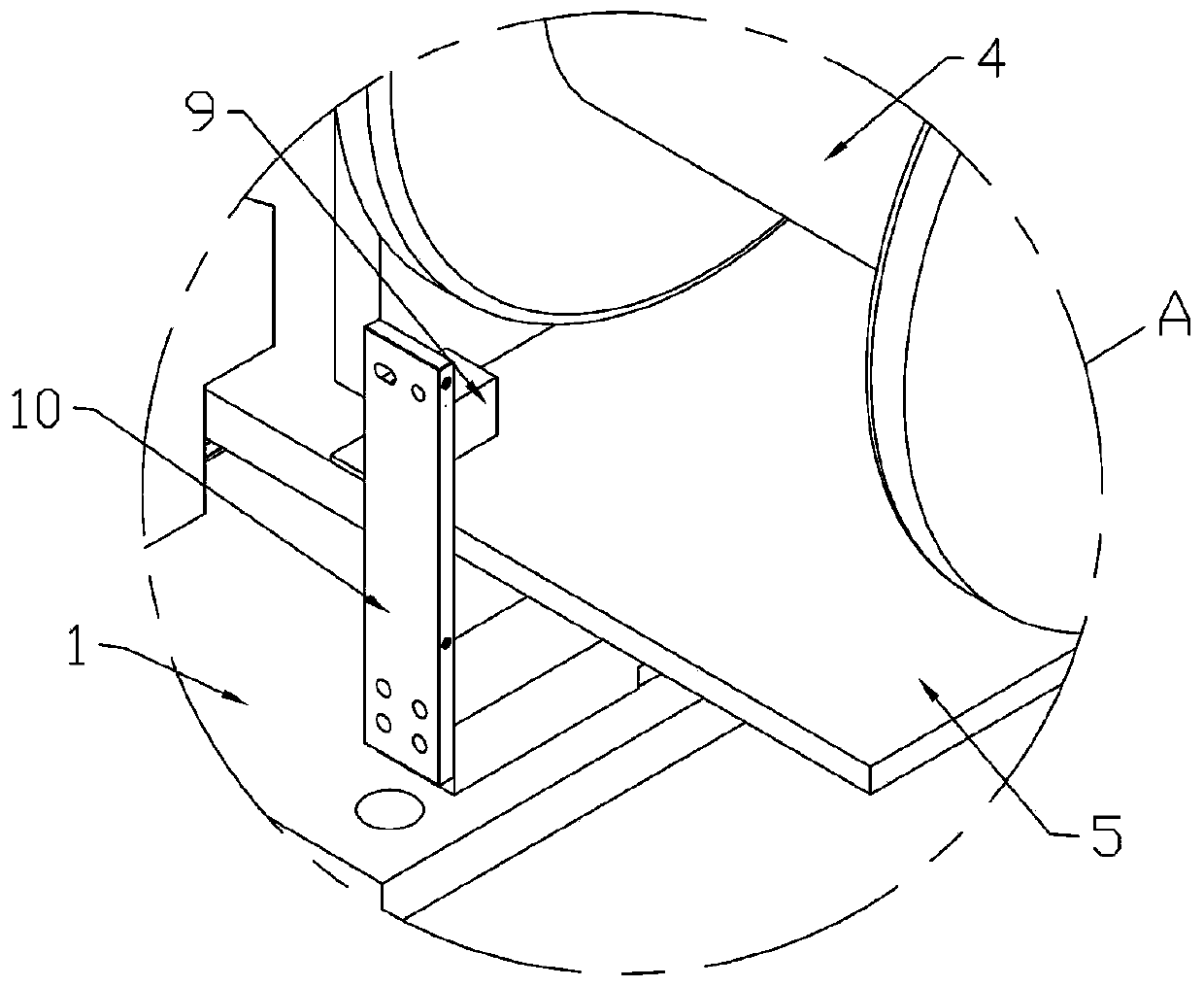

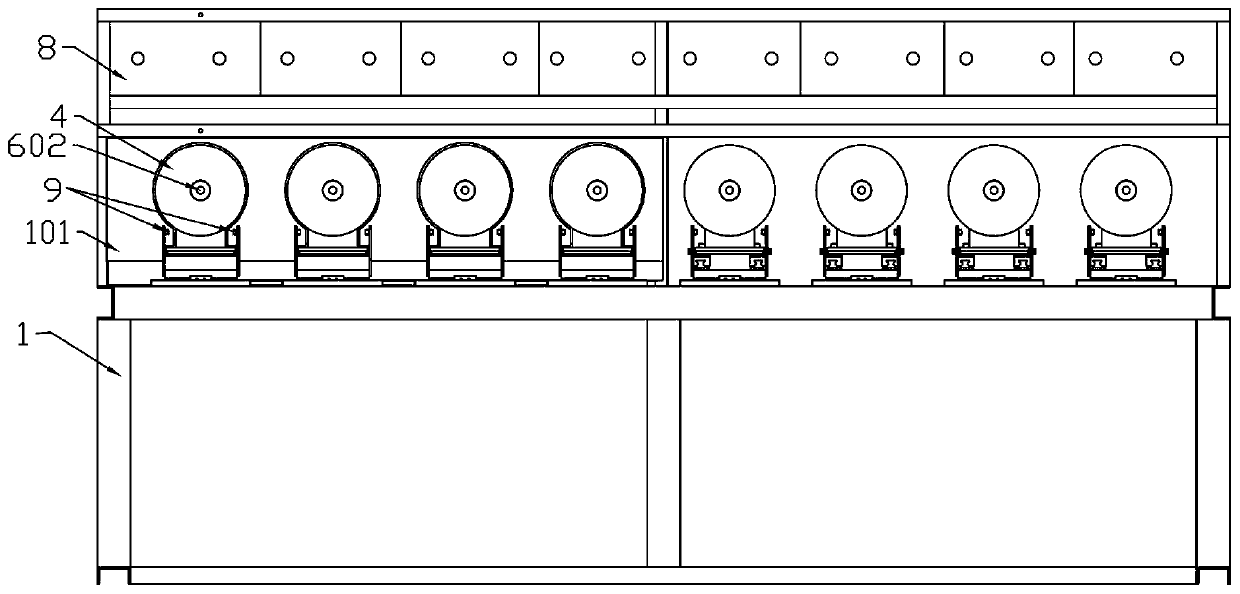

[0016] Specific embodiment 1: Please refer to Figure 1 to Figure 4 In the embodiment of the present invention, an automatic ranking take-up machine includes a frame 1, a PLC control system 2 and several winding devices 3 with the same structure installed side by side on the frame 1. The winding The device 3 is electrically connected to the PLC control system 2 respectively. A side plate 101 is provided on the side of the frame 1, and a number of installation notches 101-1 are provided on the side plate 101 corresponding to the positions of the winding device 3. The winding device 3 is installed in the installation notch 101-1 respectively, and the winding device 3 is slidably connected to the frame 1; the winding device 3 includes a supporting plate 5, a winding drum 4 and The rewinding drive member 6 that drives the rewinding drum 4 to rotate, the support plate 5 is slidably connected in the frame 1 along the Y-axis direction, the rewinding drive member 6 is fixed on the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com