Cold rolling oil for aluminum strips, and preparation method and application

A technology of cold rolling and aluminum rolling, which is applied in the field of preparation and cold rolling oil for aluminum strips, which can solve the problems of poor annealing cleanliness and achieve good annealing cleanliness and good lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

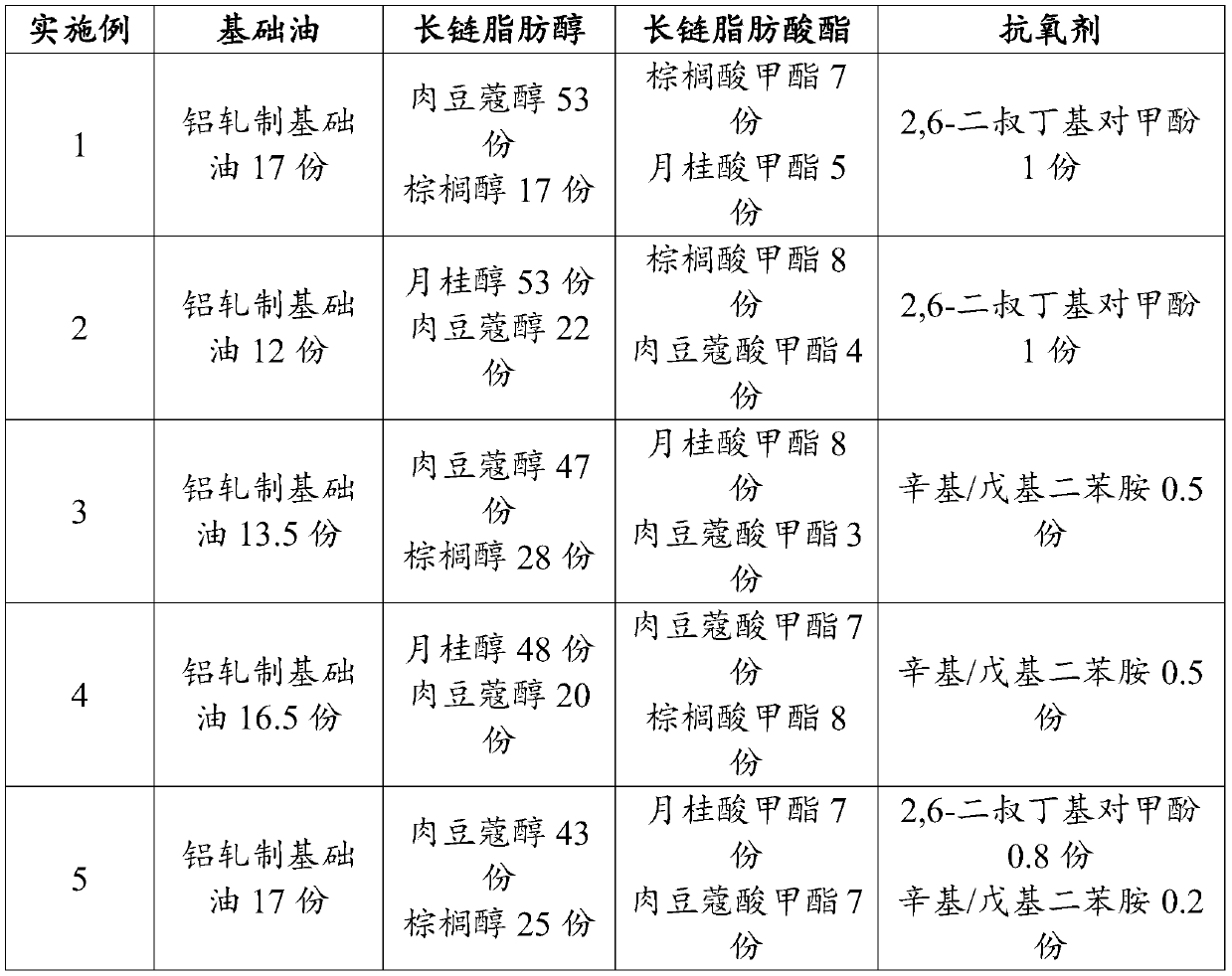

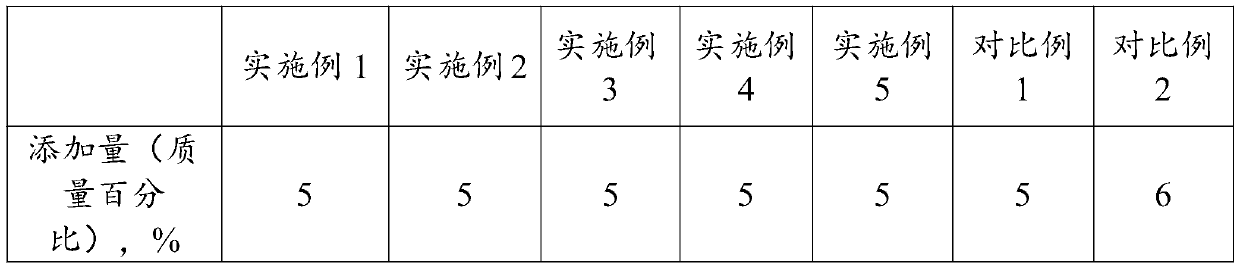

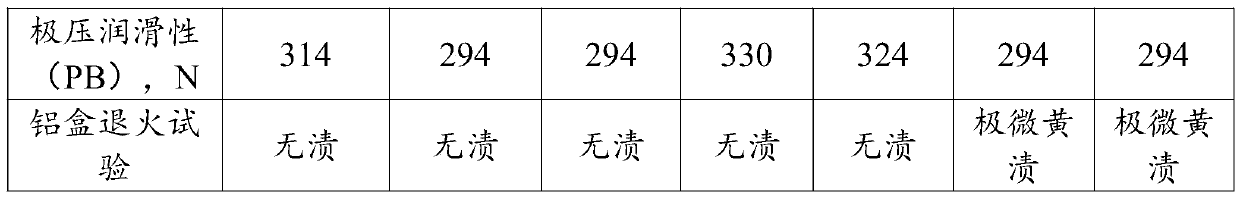

Examples

Embodiment 1

[0020] Embodiment 1 discloses a specific implementation of the cold rolling oil for aluminum strips, which consists of the following components in parts by weight:

[0021] Base oil: 17 parts of MOA-100 aluminum rolling base oil, the base oil has a distillation range of 230-270°C, a closed flash point of not less than 100°C, and a kinematic viscosity of 2.10-2.70mm at 40°C 2 / s;

[0022] Long-chain fatty alcohol: 53 parts of myristyl alcohol;

[0023] Long-chain fatty acid ester: 29 parts of methyl palmitate;

[0024] Antioxidant: 1 part of 2,6-di-tert-butyl-p-cresol.

[0025] The specific components of this example are recorded in Table 1 below, and the MOA-100 aluminum rolling base oil is produced by Huaian Qingjiang Petrochemical Co., Ltd. The preparation method of the cold-rolling rolling oil of the aluminum strip of the present embodiment is specifically as follows:

[0026] Heat the MOA-100 aluminum rolling base oil to 55°C, add the required amount of myristyl alcoho...

Embodiment 2

[0028] Embodiment 2 discloses another specific embodiment of a cold rolling oil for aluminum strips, which consists of the following components in parts by weight:

[0029] Base oil: 12 parts of MOA-100 aluminum rolling base oil, the base oil has a distillation range of 230-270°C, a closed flash point of not less than 100°C, and a kinematic viscosity of 2.10-2.70mm at 40°C 2 / s;

[0030] Long-chain fatty alcohols: 22 parts of myristyl alcohol, 53 parts of lauryl alcohol;

[0031] Long-chain fatty acid ester: 12 parts of methyl palmitate;

[0032] Antioxidant: 1 part of 2,6-di-tert-butyl-p-cresol.

[0033] The specific components of this example are recorded in Table 1 below, and the MOA-100 aluminum rolling base oil is produced by Huaian Qingjiang Petrochemical Co., Ltd. The preparation method of the cold-rolling rolling oil of the aluminum strip of the present embodiment is specifically as follows:

[0034] Heat MOA-100 aluminum rolling base oil to 45°C, add the required ...

Embodiment 3

[0036] Embodiment 3 discloses another embodiment of rolling oil for cold rolling of aluminum strips, which consists of the following components in parts by weight:

[0037] Base oil: 13.5 parts of MOA-100 aluminum rolling base oil, the base oil has a distillation range of 230-270°C, a closed flash point of not less than 100°C, and a kinematic viscosity of 2.10-2.70mm at 40°C 2 / s;

[0038] Long-chain fatty alcohols: 47 parts of myristyl alcohol, 28 parts of palmitic alcohol;

[0039] Long-chain fatty acid ester: 11 parts of methyl laurate;

[0040] Antioxidant: 0.5 part of octyl / pentyl diphenylamine. The specific components of this example are recorded in Table 1 below, and the MOA-100 aluminum rolling base oil is produced by Huaian Qingjiang Petrochemical Co., Ltd.

[0041] The preparation method of the cold-rolling rolling oil of the aluminum strip of the present embodiment is specifically as follows:

[0042] Heat the MOA-100 aluminum rolling base oil to 55°C, add the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com