Moving bottom plug

A sleeve and breathing tube technology, applied in the field of swimming bottom plugging, can solve the problems of piston effect in the unsealing process of the lower packer, increased unsealing load, difficulty in unsealing, etc., so as to eliminate the piston effect and reduce the resistance , Ease of sealing and unsealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

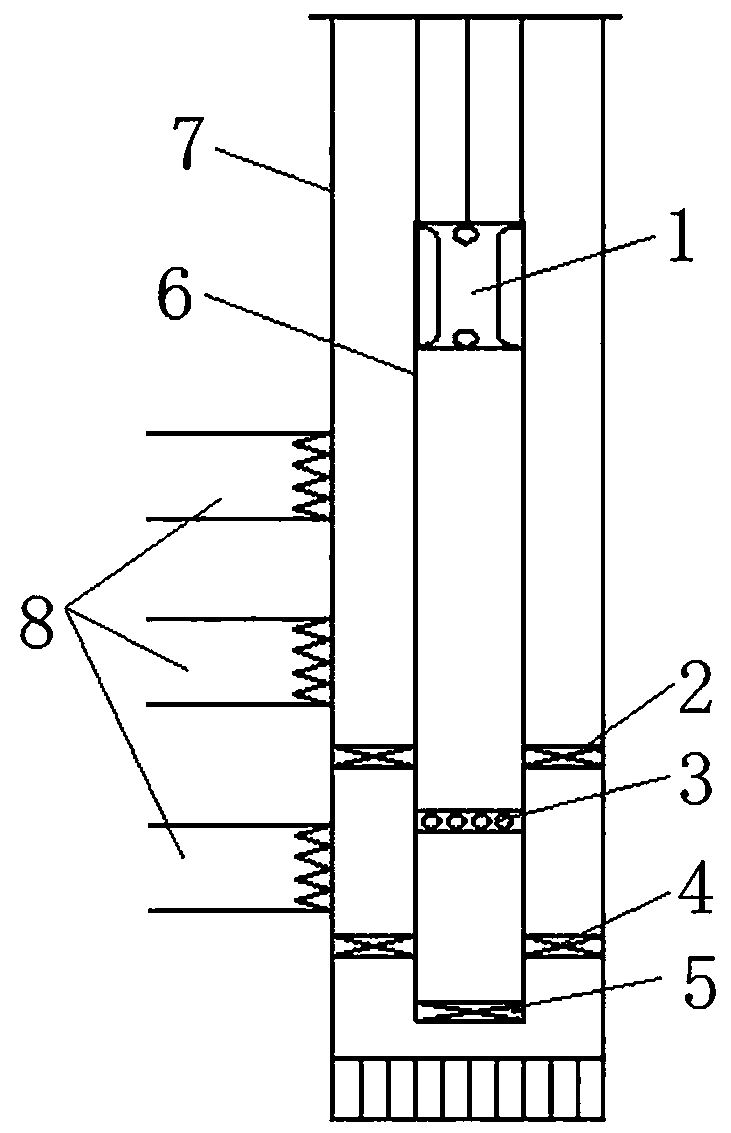

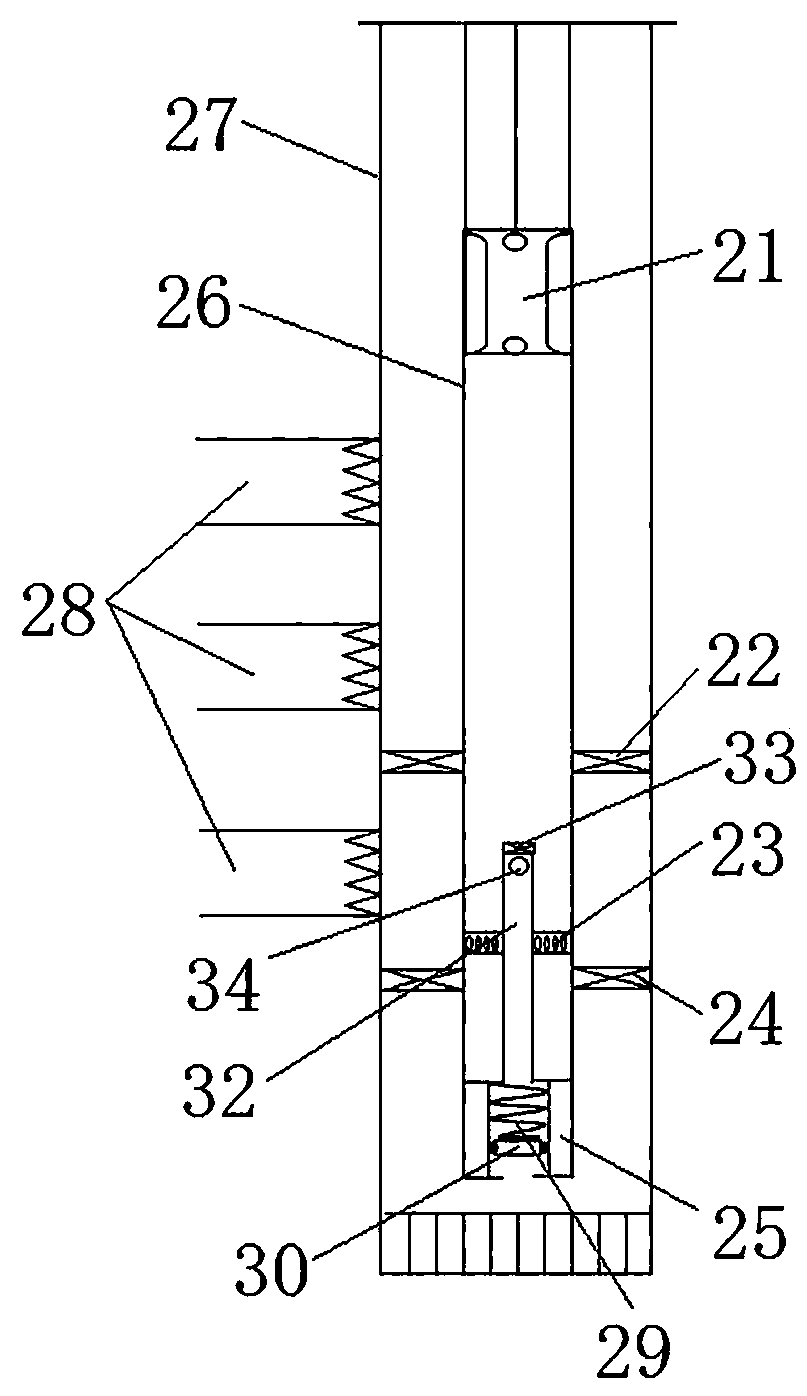

[0040] The swimming bottom plugging in this embodiment is applied to the structure of the pump-seal integrated water pipe string, such as figure 2 As shown, the pump-seal integrated water pipe string includes an oil pipe 26, and the oil pipe 26 includes a large number of pipe string sections connected in series. The oil well pump 21 is arranged inside the oil pipe 26, and a sucker rod is connected to the upper end of the oil well pump 21, and the oil sucker rod drives pumping. Oil pump 21 carries out oil pumping operation. The oil pipe 26 is connected with an upper packer 22 and a lower packer 24 below the oil pump 21, and the upper packer 22 and the lower packer 24 are arranged at intervals in the vertical direction to separate each oil layer 28 .

[0041] In this embodiment, the upper packer 22 is a Y111 packer, and the lower packer 24 is a Y211 packer, wherein both the Y111 packer and the Y211 packer are mature products in the prior art.

[0042] Among them, the oil pipe...

specific Embodiment 2

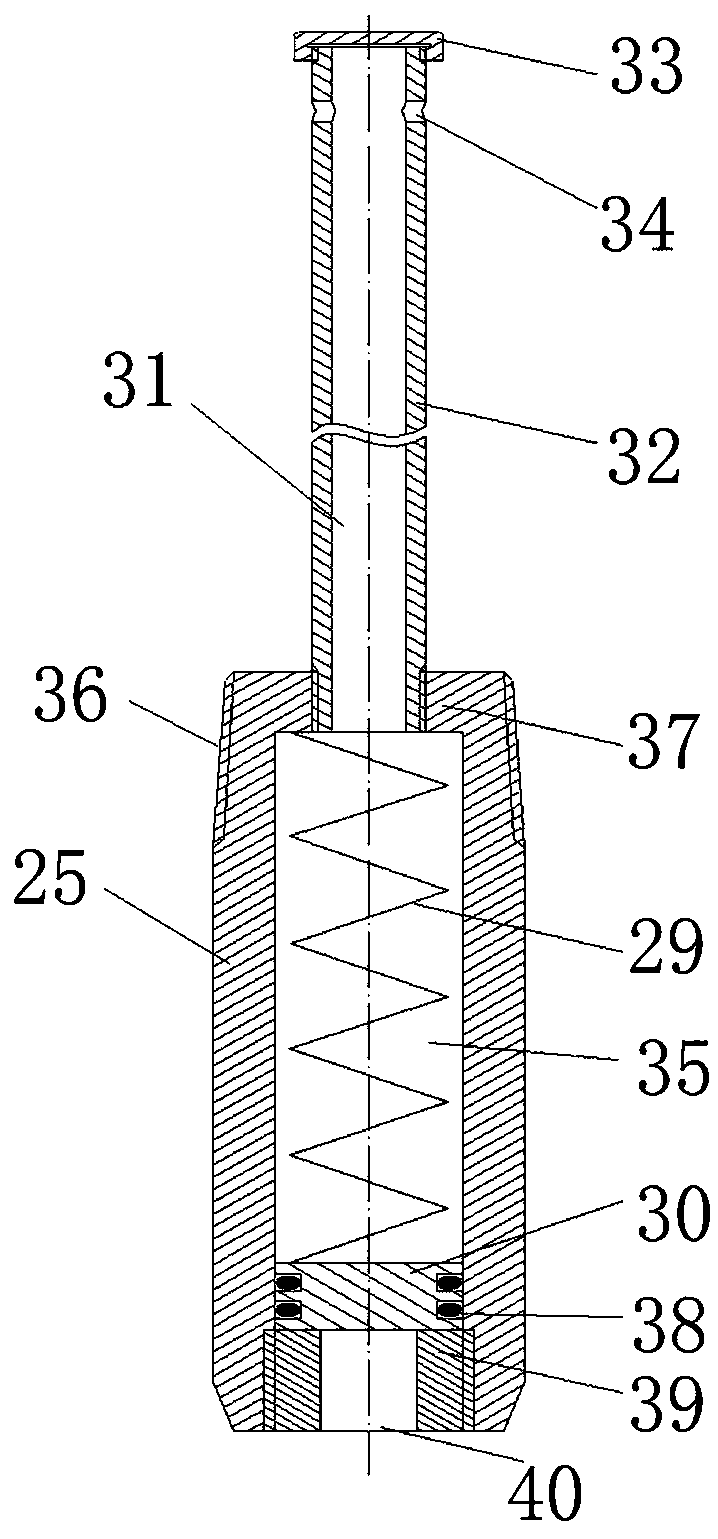

[0060] The difference from the specific embodiment 1 is that in embodiment 1, a wire plug 33 is provided at the opening of the upper end of the breathing tube 32, and a breathing hole 34 is provided on the breathing tube 32, and the breathing hole 34 is used to communicate with the deposition ring cavity and the breathing tube 32. The inner cavity of the breathing tube 34 is set close to the plug 33. In this embodiment, the opening at the upper end of the breathing tube is not blocked, and the upper end of the breathing tube is bent towards the sleeve, that is, the opening of the breathing tube is facing the sleeve. At this time The sediment in the oil pipe will not enter into the breathing pipe, so it can prevent impurities from depositing on the piston in the sleeve and blocking the piston. Wherein, the opening of the breathing tube in this embodiment forms a breathing port, and the breathing port provides a passage for liquid in and out for the up and down movement of the pi...

specific Embodiment 3

[0062] The difference from Embodiment 1 is that in Embodiment 1, the plugging structure is a wire plug 33, and the wire plug 33 is used to block the upper opening of the breathing tube 32. In this embodiment, the plugging structure is welded on the upper end of the breathing tube. Sealing plate at the opening. In other embodiments, the blocking structure is a cover integrally formed with the breathing tube; or the blocking structure is a sealing plate fixedly connected to the upper opening of the breathing tube by bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com