Acoustic insulation cover, design method for acoustic insulation cover, and acoustic insulation method for compressor

A technology of sound insulation cover and compressor, applied in mechanical equipment, machine/engine, liquid variable capacity machinery, etc., can solve the problem of limited low frequency noise reduction ability of sound insulation cover, compressor noise leakage, poor sound absorption effect, etc. To achieve the effect of improving sound insulation and noise reduction, improving noise reduction reliability, and improving sound absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

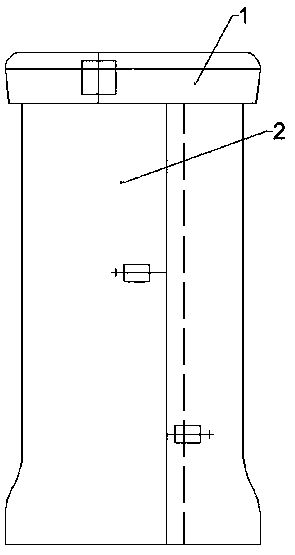

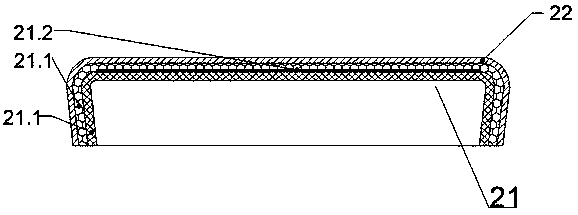

[0040] The sound insulation cover includes a cylindrical side wall 1 and a top cover 2 sealed on the top of the side wall 1. Both the side wall 1 and the top cover 2 include a sound-absorbing layer for absorbing noise and for blocking noise from radiating outwards. The sound-absorbing layer, the sound-absorbing layer and the sound-insulating layer are bonded from the inside to the outside, and it is characterized in that the sound-absorbing layer has at least two layers of sound-absorbing cotton layers, and a sound-absorbing cotton layer is formed between adjacent sound-absorbing cotton layers. A sound-absorbing cavity and a sound-absorbing film that can absorb middle and low frequency noises are arranged in the sound-absorbing cavity.

[0041]The above-mentioned sound insulation cover comprises a side wall 1 and a top cover 2, and a sound-absorbing cavity is formed in the sound-absorbing layer of the side wall 1 and the top cover 2, and a sound-absorbing film is arranged in th...

Embodiment 2

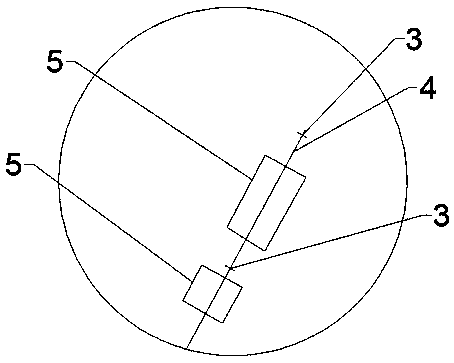

[0048] The difference from Embodiment 1 is that: the side wall sound-absorbing layer 11 is provided with a support column 13 to prevent the sound-absorbing cavity in the side wall sound-absorbing layer 11 from being squeezed, and the support column 13 penetrates the side wall sound-absorbing layer 11 and its outer end is in contact with the enclosure sound-insulation layer 12, the length of the support column 13 is not less than the thickness of the side enclosure sound-absorbing layer 11, and the hardness of the support column 13 is greater than the hardness of the side enclosure sound-absorption layer 11;

[0049] The material of the support columns 13 is the same as that of the side wall sound insulation layer 12, and the support columns 13 are distributed in the position where the side wall sound absorption layer 11 is laid with the sound absorption film 2 11.2, and are evenly spaced in an array.

[0050] Support columns 13 are provided in the side wall sound-absorbing laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com