Buffer valve, rotation hydraulic system and crane

A technology of buffer valve and hydraulic oil, applied in the field of hydraulic components, can solve problems such as difficulty, high cost, poor effect, etc., and achieve the effect of good buffering and reset effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

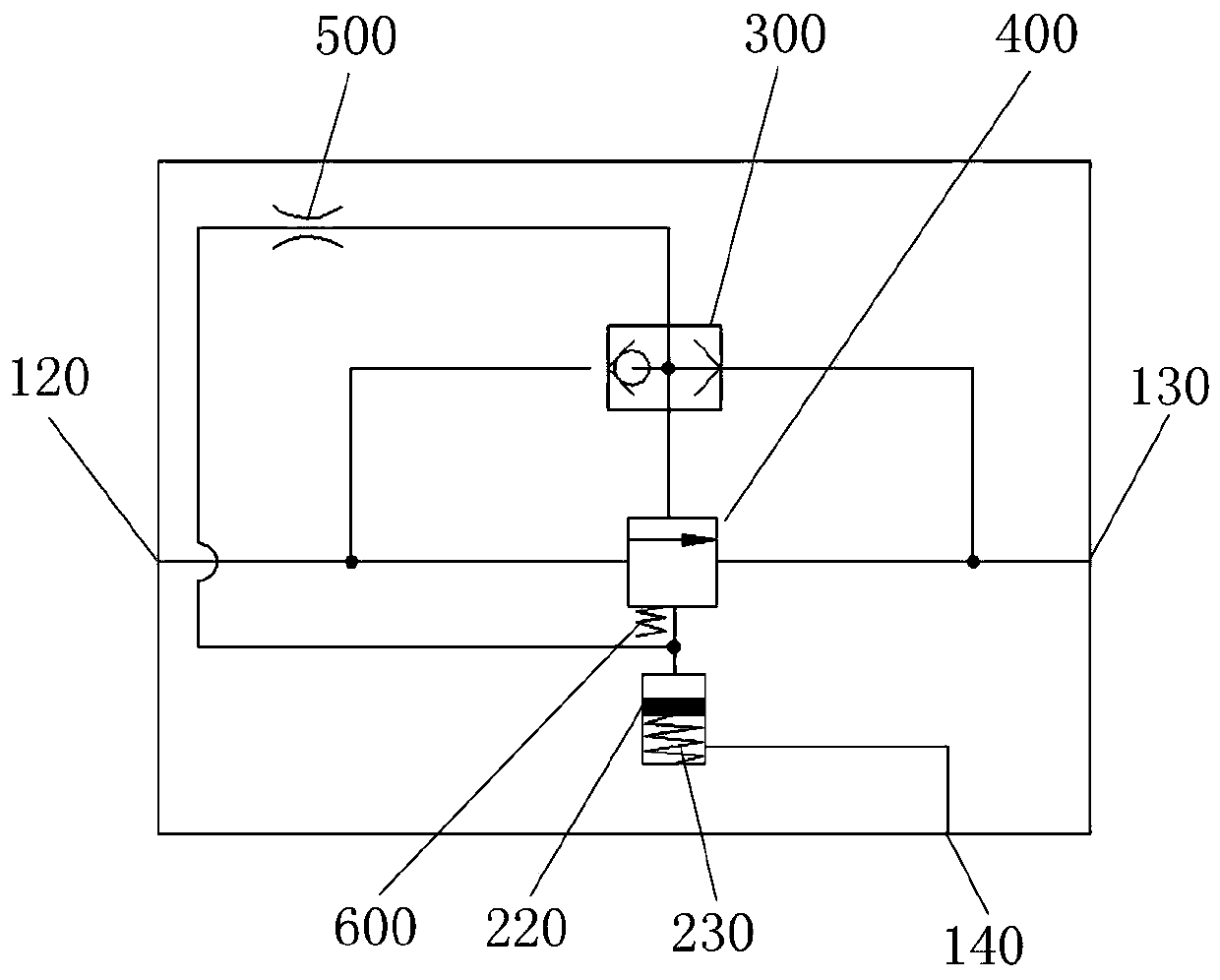

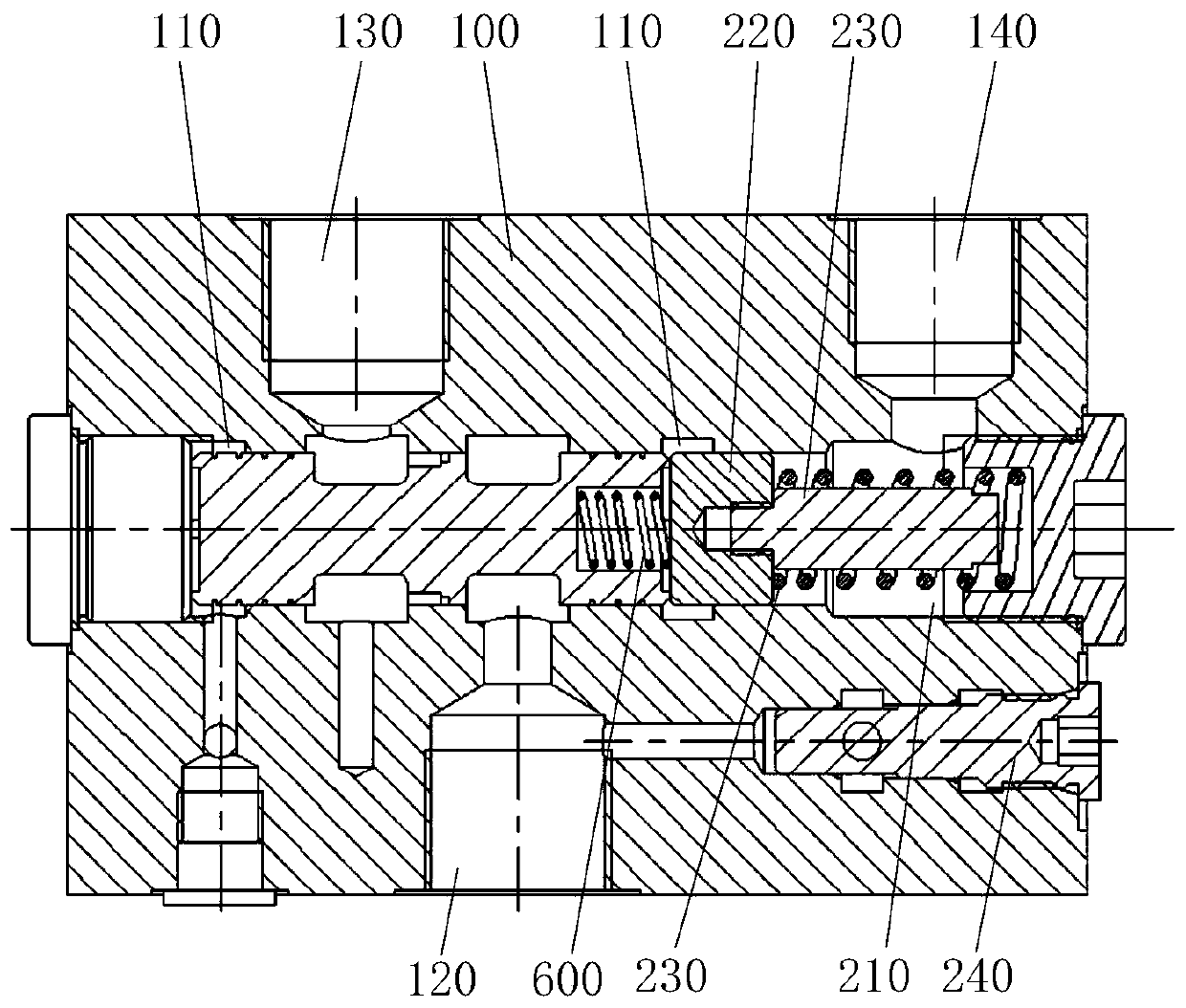

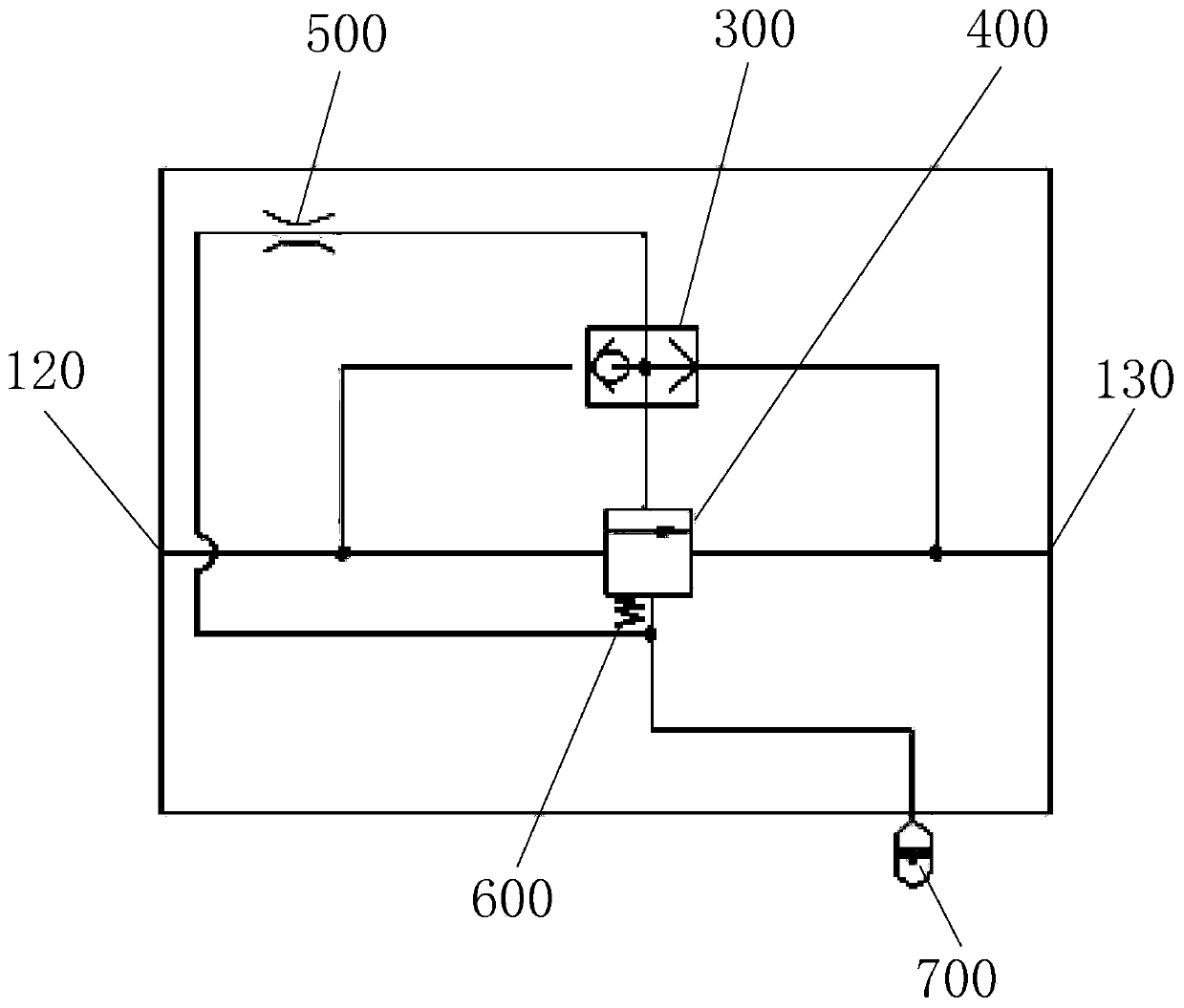

[0031] As an implementation, the variable displacement assembly includes a second chamber 210, a variable displacement piston 220 and an elastic member. The second chamber 210 is arranged on the buffer valve body 100 and communicates with the first chamber 110. The parts are all disposed in the second chamber 210 , and the elastic part is located on the side of the variable displacement piston 220 facing away from the first chamber 110 , so that the variable displacement piston 220 has a tendency to move close to the first chamber 110 .

[0032] Specifically, the hydraulic oil flowing out from the shuttle valve 300 enters the left end of the first chamber 110 through the first oil passage, and the hydraulic oil of the buffer spool 400 figure 2 The left end surface shown produces force, and the original hydraulic oil on the right side of the buffer spool 400 pushes the variable displacement piston 220 to move to the right and enters the second chamber 210, preventing the origin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com