End part linear divider

A divider and straight line technology, used in instruments, scientific instruments, analytical materials, etc., can solve the problems of inconvenient installation, low completeness, material adhesion, etc., and achieve the effect of small occupied space and high completeness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

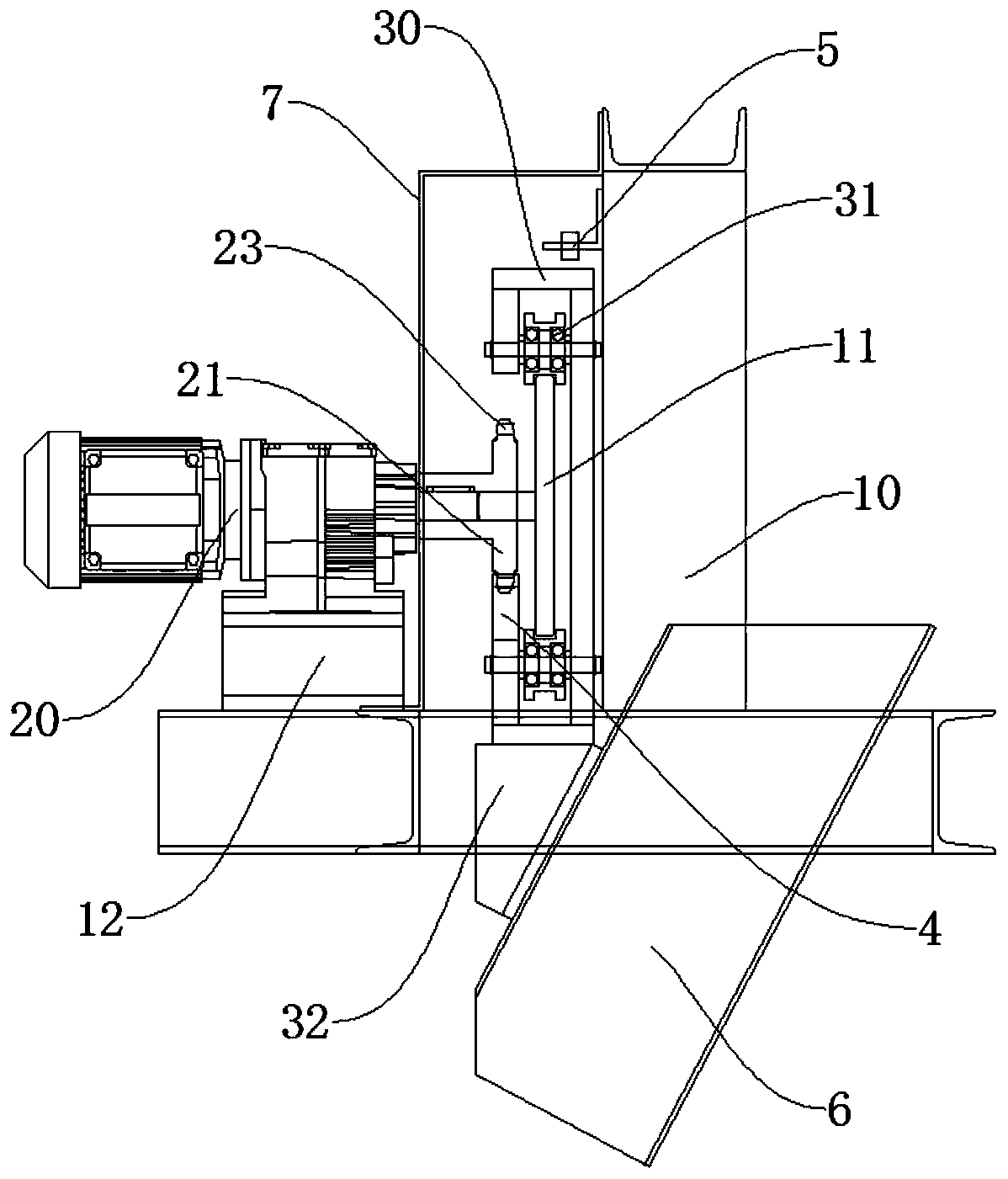

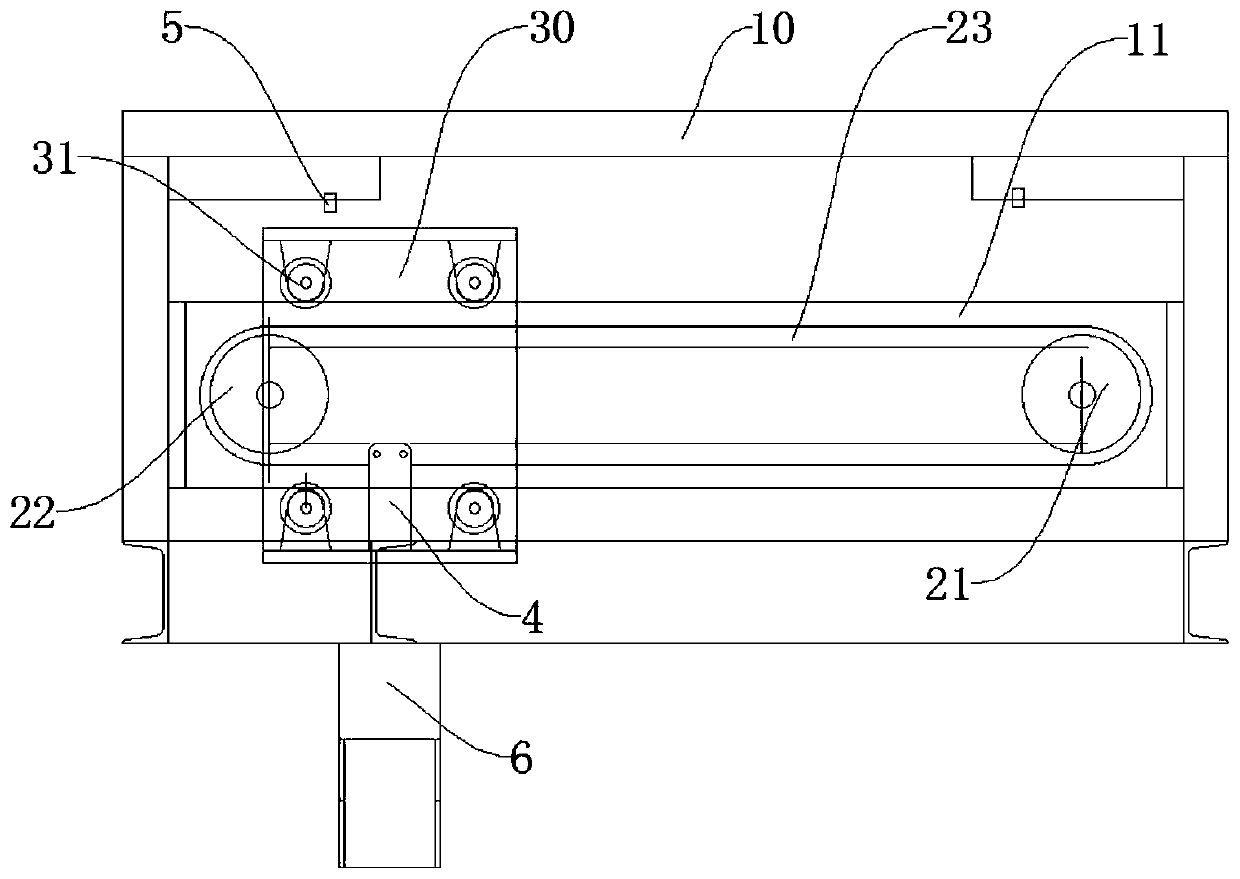

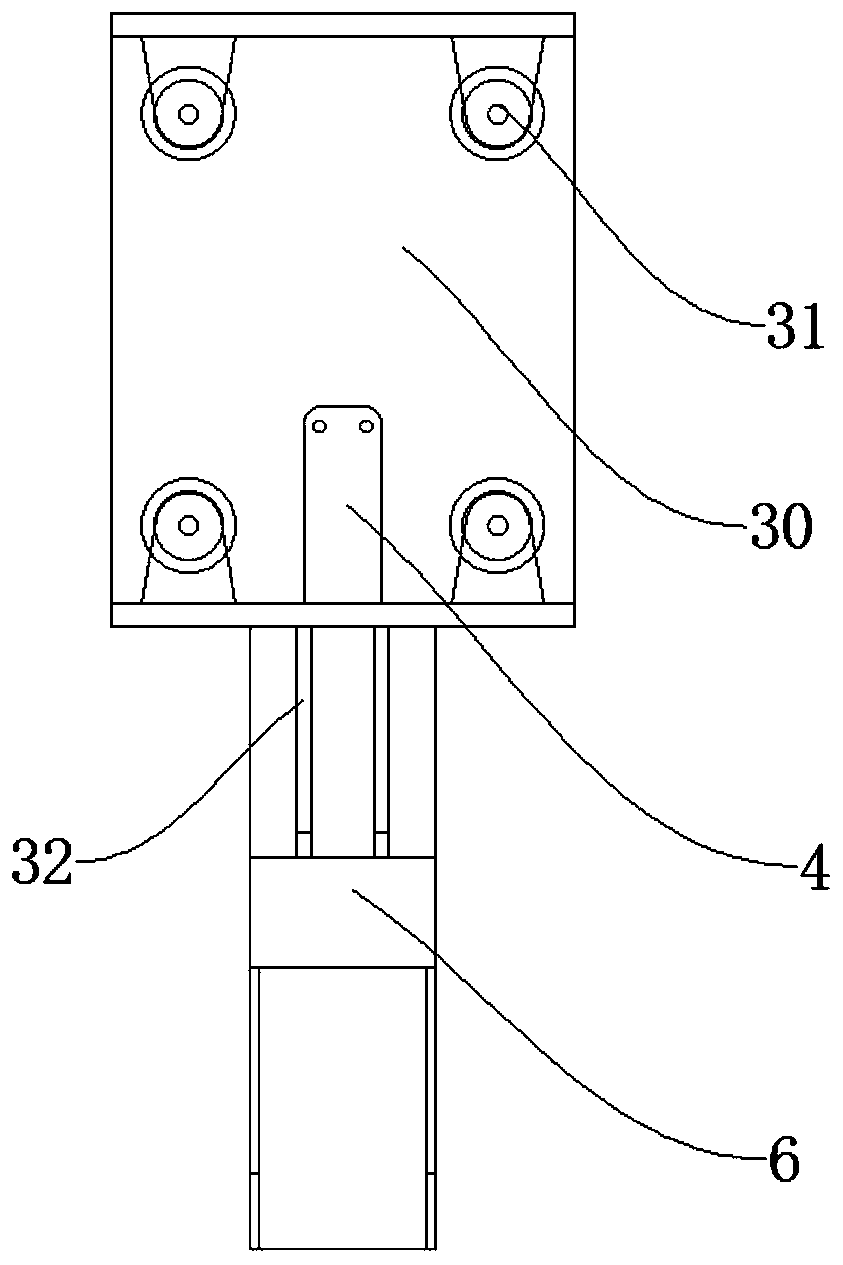

[0027] The invention discloses an end linear shrinkage divider, referring to figure 1 As shown, the splitter includes a frame 10, on which a guide rail plate 11 is fixedly installed, and the guide rail plate 11 is a complete steel plate, and a sampling trolley is slidably connected to the guide rail plate 11, and a sampling blade 6 is fixedly installed on the sampling trolley, The sampling trolley is used to drive the reciprocating motion of the sampling blade 6 .

[0028] ginseng figure 1 As shown, an organic casing 7 is also installed on the frame 10, the casing 7 is a semi-sealed structure, and the bottom is a full...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com