Lens assembly with electric contacts, photoelectric detector and laser radar

A technology of photodetectors and electrical contacts, applied in the direction of lenses, contact parts, radio wave measurement systems, etc., can solve problems such as difficulty in reducing distance, difficulty in realizing light and thin products, space optimization settings, and inability to effectively compress device heights, etc. , to achieve the effect of optimizing the space setting, improving the efficiency of light energy utilization, and improving the ability of photoelectric signal collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The implementation process of the technical solution of the present invention is described below in conjunction with specific embodiments, which are not intended to limit the present invention.

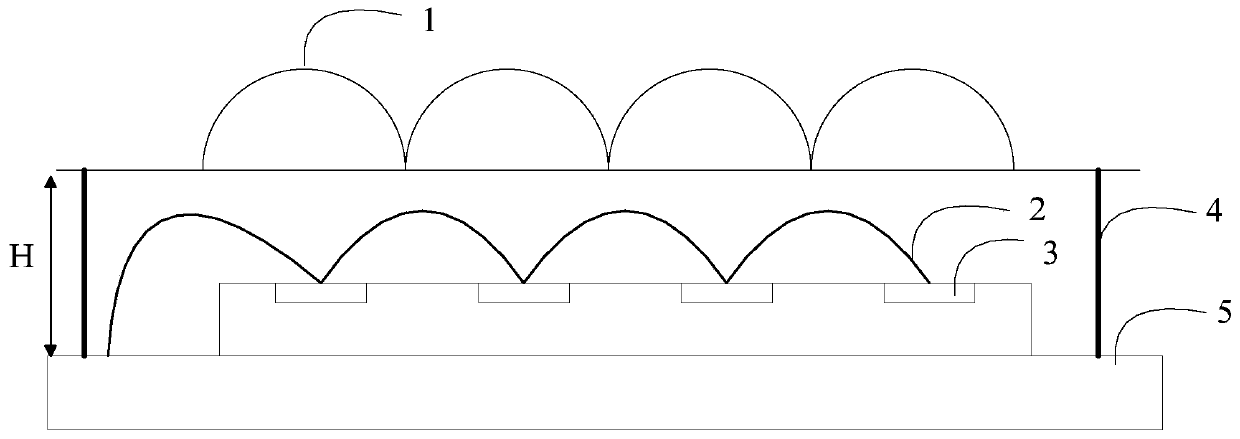

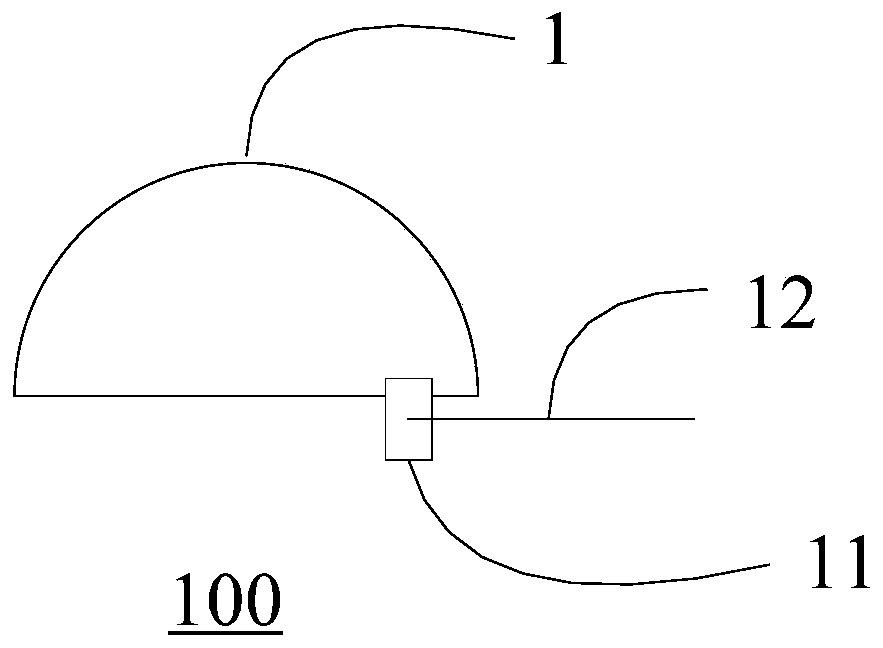

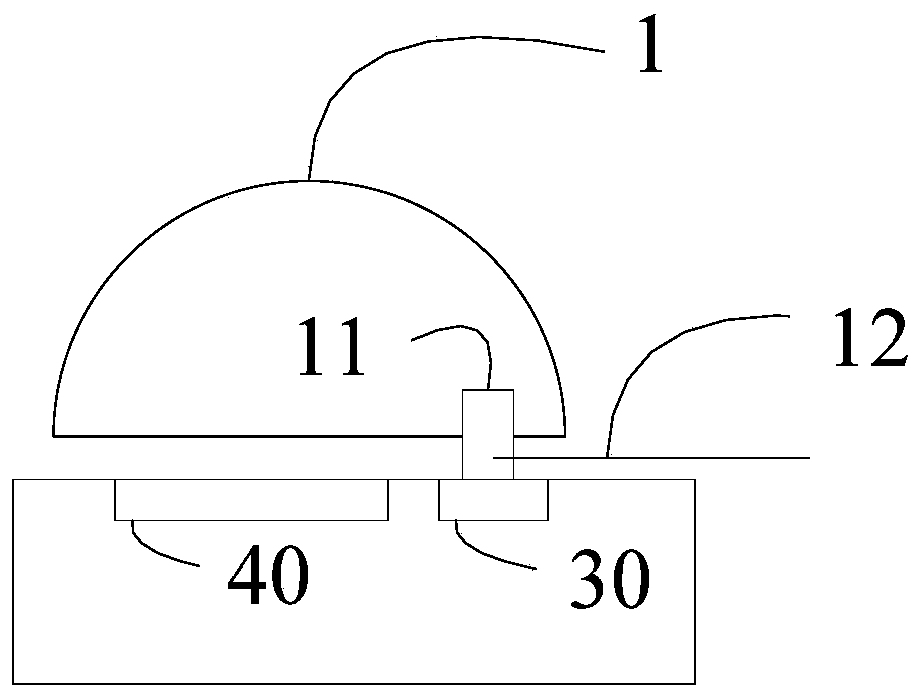

[0035] Such as Figure 2A , 2B , 2D are schematic cross-sectional structural diagrams of the lens assembly with electrical contacts of the present invention.

[0036] The lens assembly 100 includes an optical lens 1 and electrical contacts 11 .

[0037] An optoelectronic device is correspondingly disposed under the lens assembly 100 , and the electrical contact 11 is used to connect the optoelectronic device corresponding to the optical lens.

[0038] The optoelectronic device may be a photodetector. The electrical contact 11 is electrically connected to the connection part 30 of the optoelectronic device, and the connection part 30 can be a pad or an electrode. The photoactive surface 40 of the optoelectronic device faces the rear section of the optical lens 1 .

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com