An integrated device for automatic mildew removal and dehydration of textiles

A textile, automatic technology, used in water supply devices, drying solid materials, drying solid materials without heating, etc., can solve the problems of textile mold, fabric surface damage, and inconvenient batch processing of fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

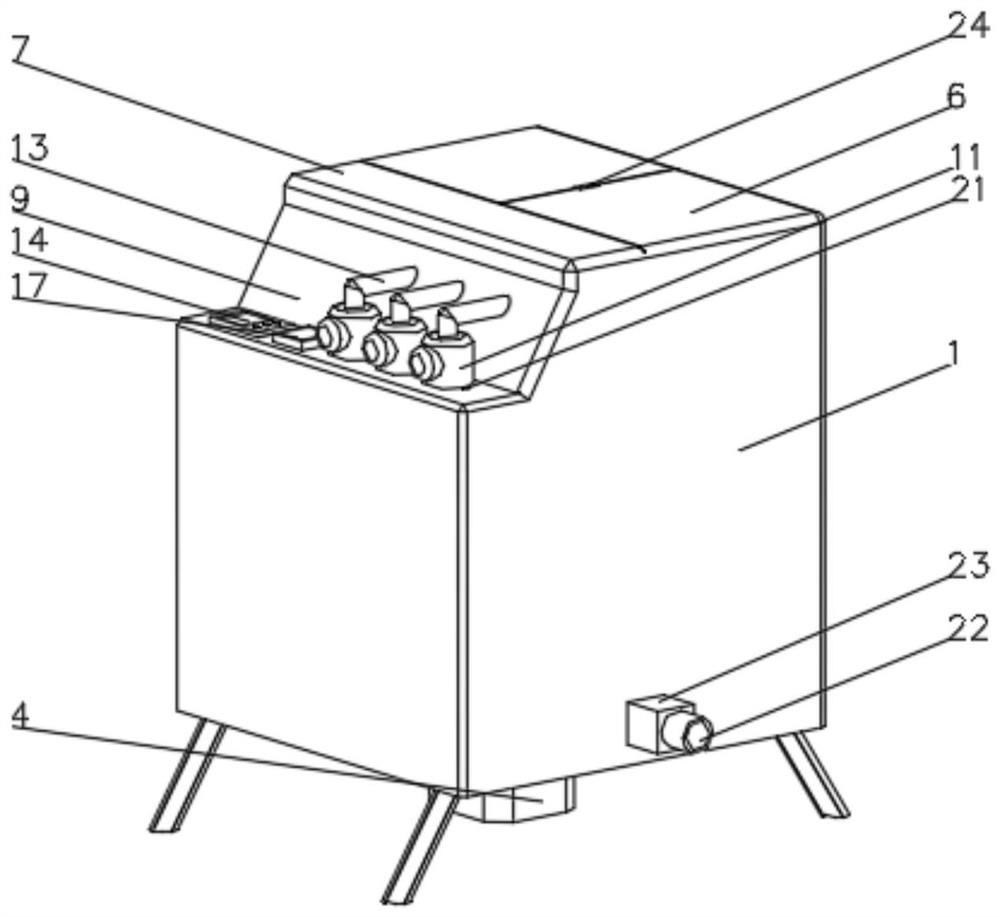

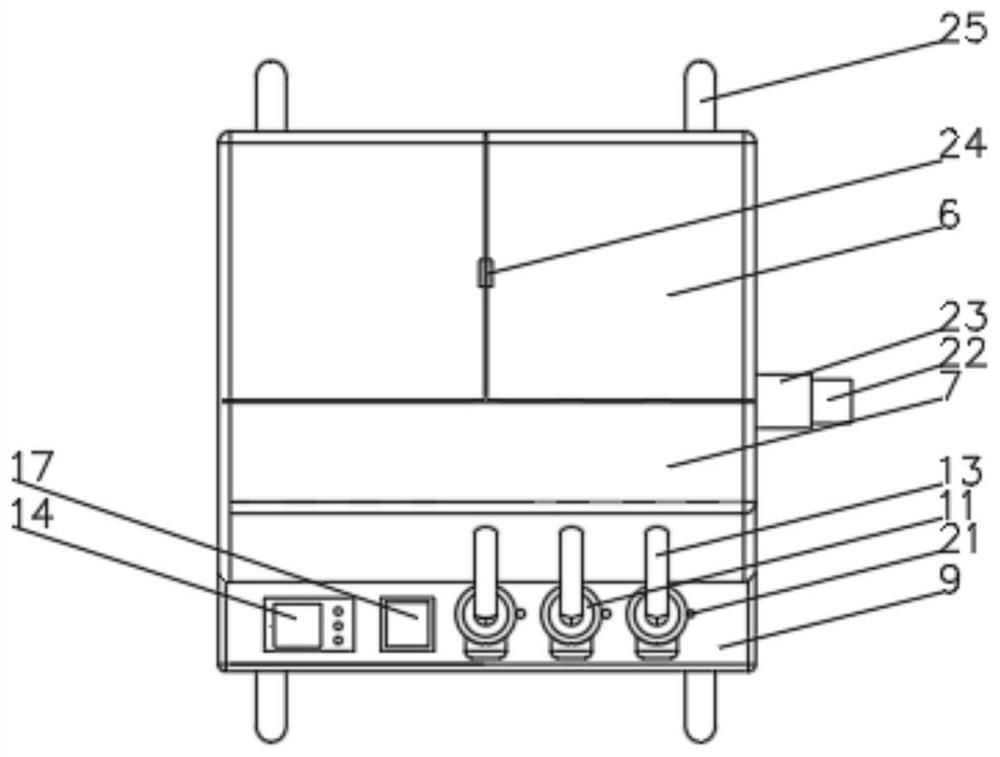

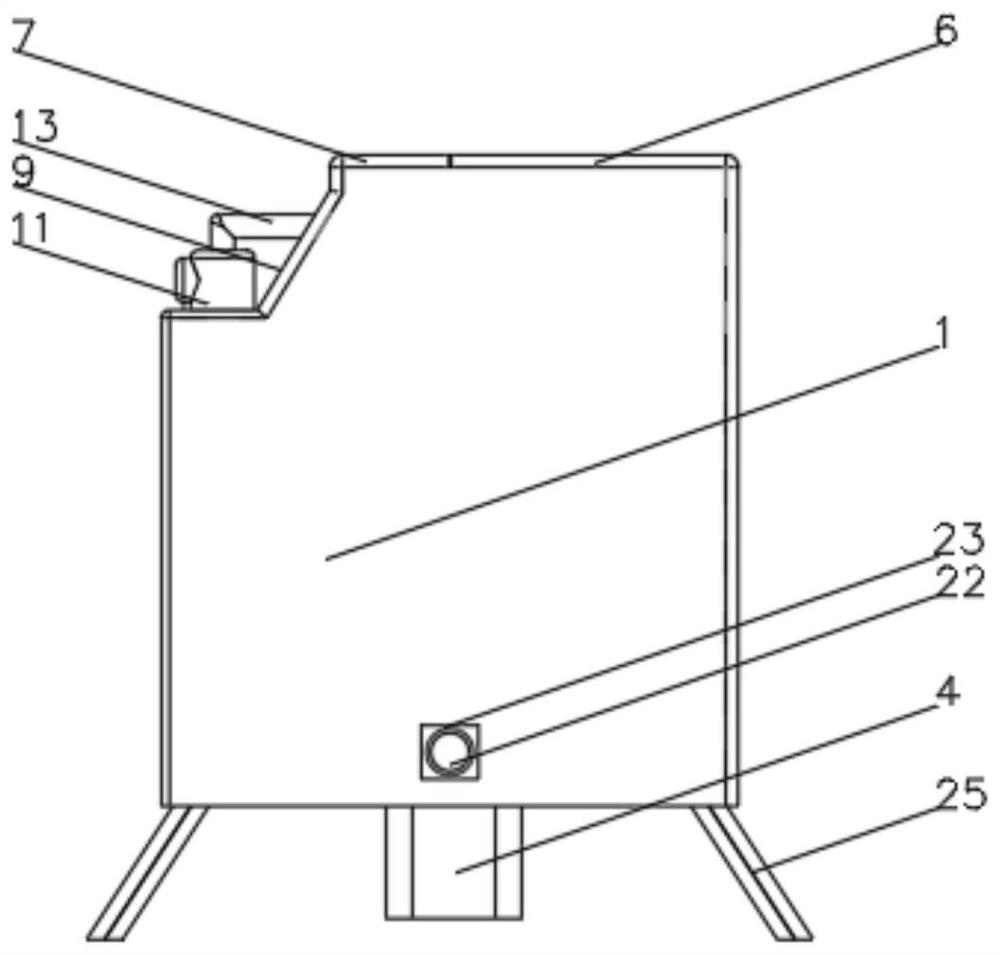

[0032] see Figure 1-4, the present invention provides a technical solution: an integrated device for automatic mildew removal and dehydration of textiles, comprising a fixed shell 1, a rotating seat 2 is fixedly connected to the center of the bottom of the inner wall of the fixed shell 1, and a mildew removing barrel 3 is fixedly connected to the top of the rotating seat 2 , the bottom of the fixed housing is fixedly connected to the rotating motor 4, the drive shaft of the rotating motor 4 runs through the bottom of the fixed housing 1 and extends to the inside of the fixed housing 1, the end of the driving shaft of the rotating motor 4 located inside the fixed housing 1 runs through the rotating seat 2 and is connected with the mildew removing The bottom of the barrel 3 is fixedly connected, and the top part of the fixed shell 1 located on one side of the sliding cover 6 is fixedly connected with a fixed cover 7. The top of the fixed cover 7 is provided with a functional tab...

Embodiment 2

[0034] see Figure 1-4 , on the basis of Embodiment 1, the present invention provides a technical solution: the bottom of the fixed cover 7 is fixedly connected with a light source 15, and the bottom of the fixed housing 1 is fixedly connected with a spectrum receiver 16, and both the light source 15 and the spectrum receiver 16 are controlled by PLC Controlled by the panel 14, the output end of the spectrum receiver 16 is electrically connected to a spectrum analyzer 17, and the spectrum analyzer 17 is fixed on the top end of the functional table 9. When the dissolving agent is used, the plc control panel 14 controls the light source 15 to open, and the light source 15 The light is emitted and irradiated on the spectrum receiver 16 through the dissolving agent. After receiving the light, the spectrum receiver 16 transmits the optical signal to the spectrum analyzer 17. The spectrum analyzer 17 analyzes the light signal to calculate the light transmittance. When the dissolving ...

Embodiment 3

[0036] see Figure 1-5 , On the basis of Embodiment 1, the present invention provides a technical solution: there are three liquid storage barrels 10 and their interiors are respectively filled with dissolving agent, liquid soap and water, and the liquid suction pumps 11 are provided with three and are respectively located in The liquid storage barrels 10 correspond one-to-one, and the dissolving agent, soap oil and water can be sequentially added to the interior of the device. The dissolving agent needs a certain humidity when dissolving the textile to ensure that the textile will not generate static electricity or shrink. The hydrophilic liquid provided by the liquid soap molecule The base can make the water better combine with the oily solvent, and it is convenient to protect the placed items.

[0037] Example of how to use,

[0038] When removing mildew from the textiles, slide the sliding cover 6 to open the top of the fixed housing 1, put the textiles through the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com