Micro-negative pressure recycling and circulating treatment system of VOCs purification treatment device

A technology of purification treatment and recycling treatment, applied in gas treatment, chemical instruments and methods, vapor condensation, etc., can solve problems such as environmental pollution, and achieve the effect of reducing tar residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

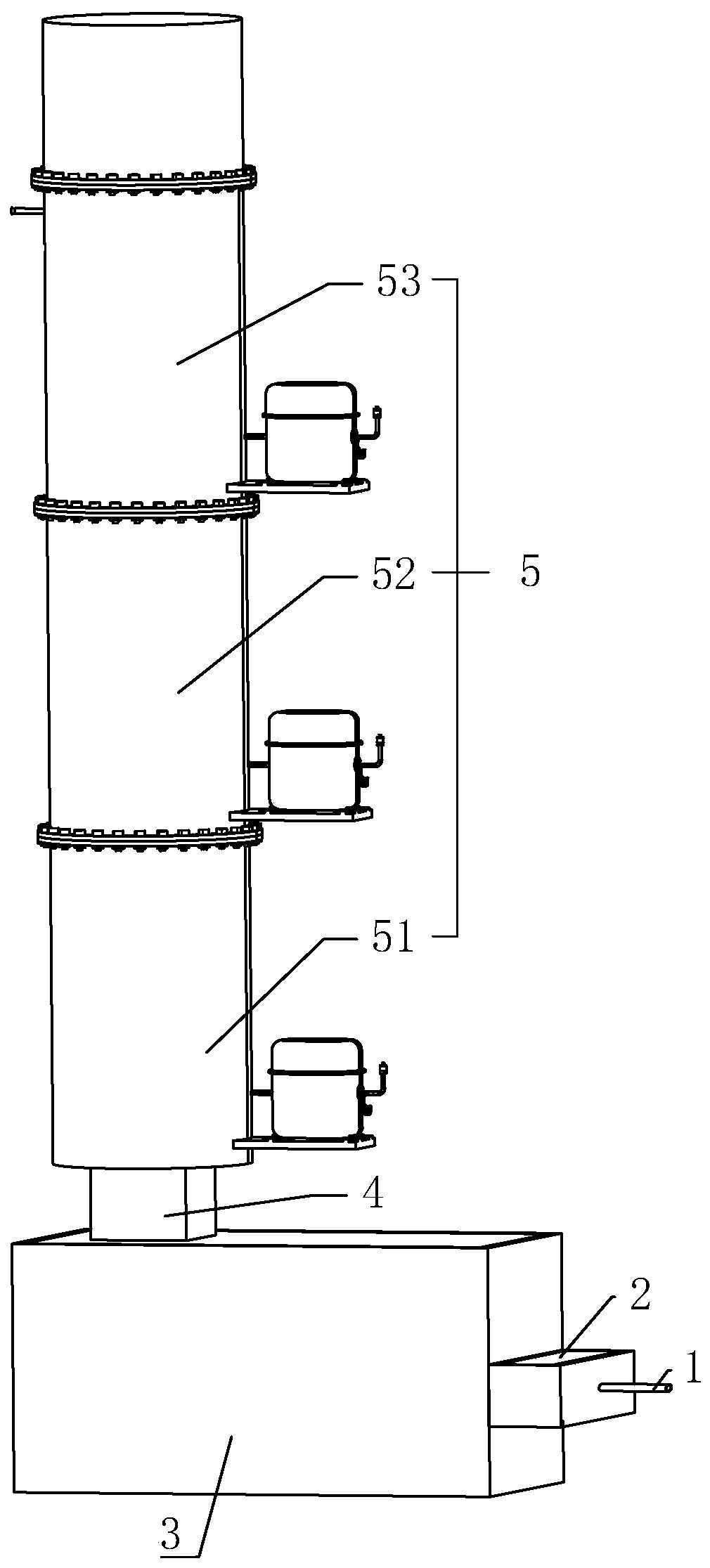

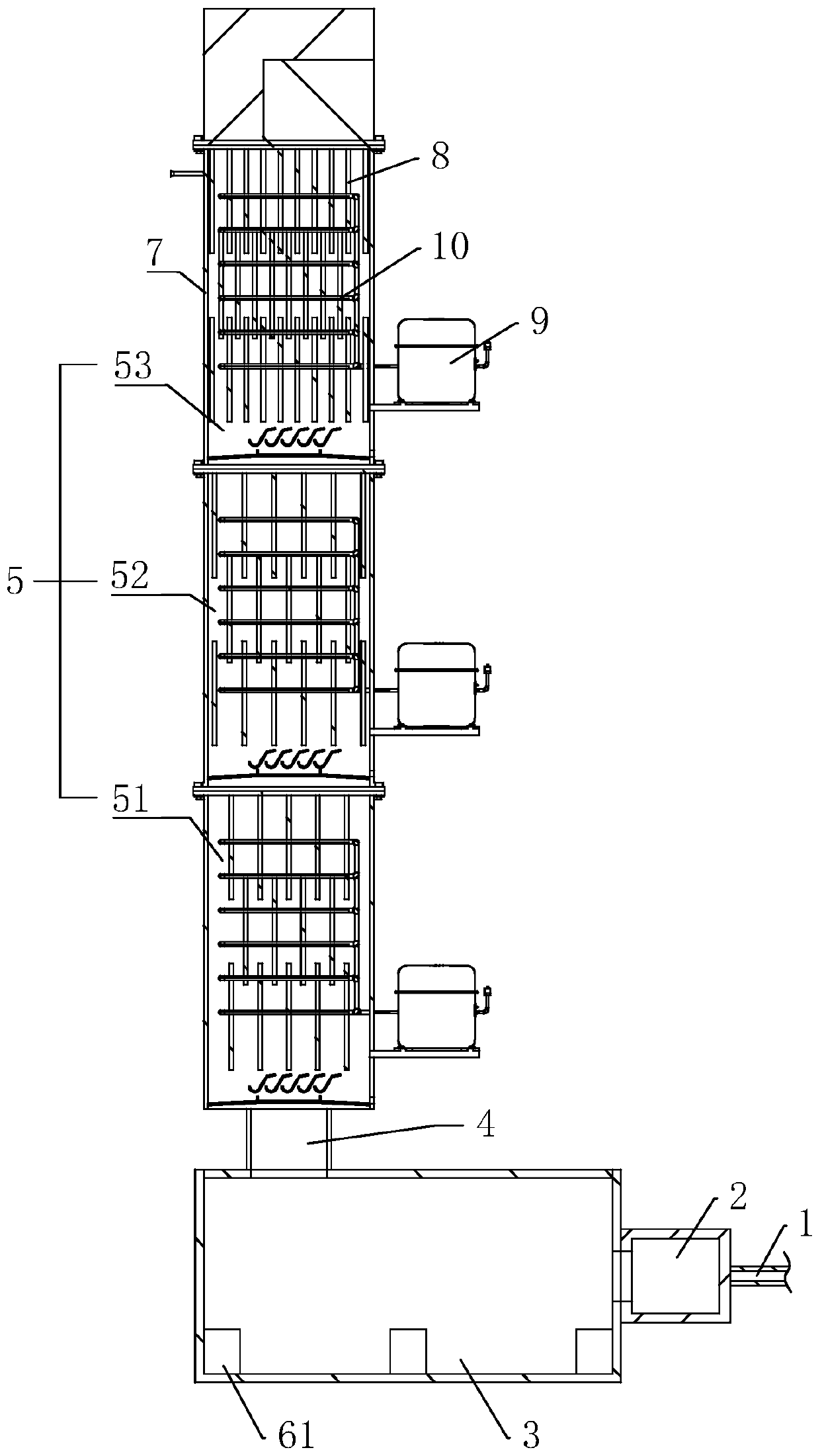

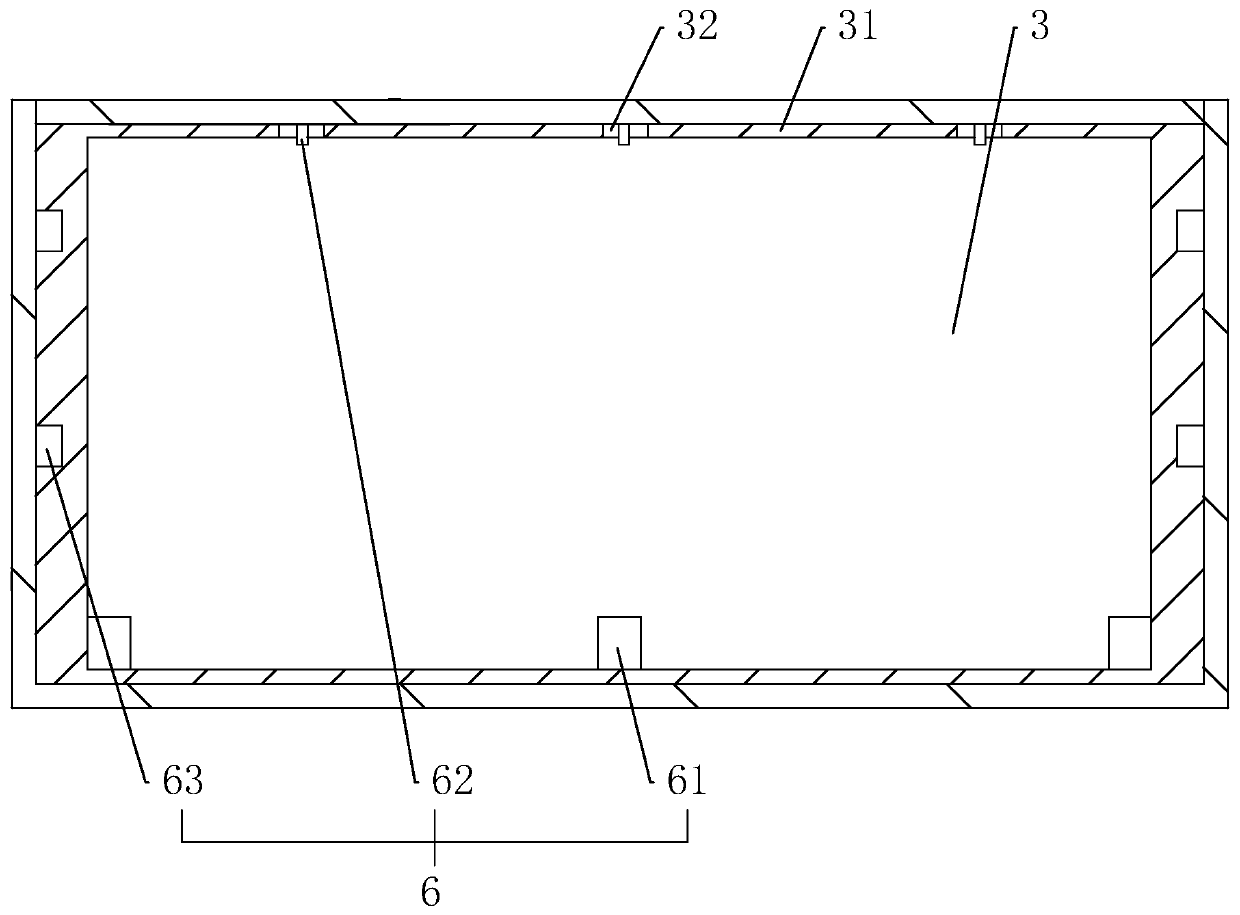

[0033] Embodiment: a kind of micro-negative pressure recovery circulation treatment system of VOCs purification treatment device, such as figure 1 and 2 As shown, it includes a gas collection pipe 1, a negative pressure pump 2 connected to it, a collection box 3 connected to the negative pressure pump 2, a delivery pipe 4 connected to the collection box 3, and a collection and processing system 5 connected to the delivery pipe 4, A pressurizing device 6 is arranged in the collection box 3 . The non-condensable gas in the VOCs that has been treated once enters the collection box 3 from the gas collection pipe 1 under the action of the negative pressure pump 2, and is subjected to pressurized collection treatment, so that the non-condensable gas in the VOCs returns to its original properties, and then enters the The collection and treatment system 5 performs purification work again, and effectively treats the purified waste gas (VOCs) again to realize the advantage of zero emis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com