A kind of automobile spraying method utilizing color paint sharing system

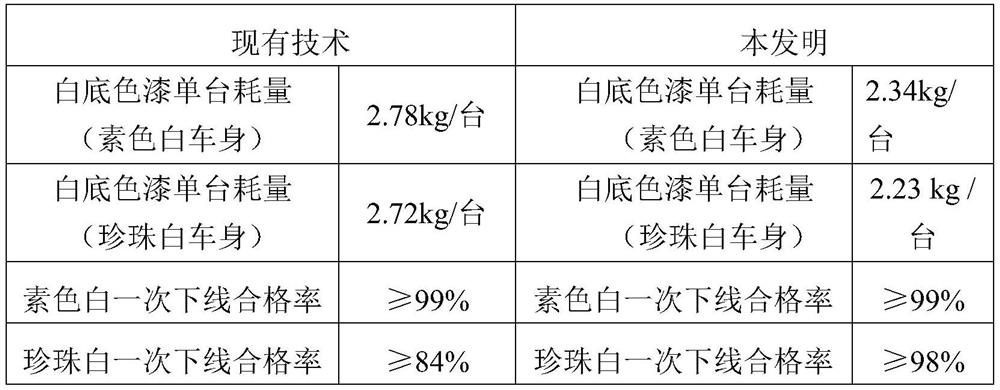

A technology for color paints and automobiles, which is applied to devices for coating liquid on surfaces, coatings, and special surfaces, etc. It can solve problems such as high cost pressure, large white resource occupation, and high risk of pinholes, and achieves increased renewal rates, The effect of reducing paint scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

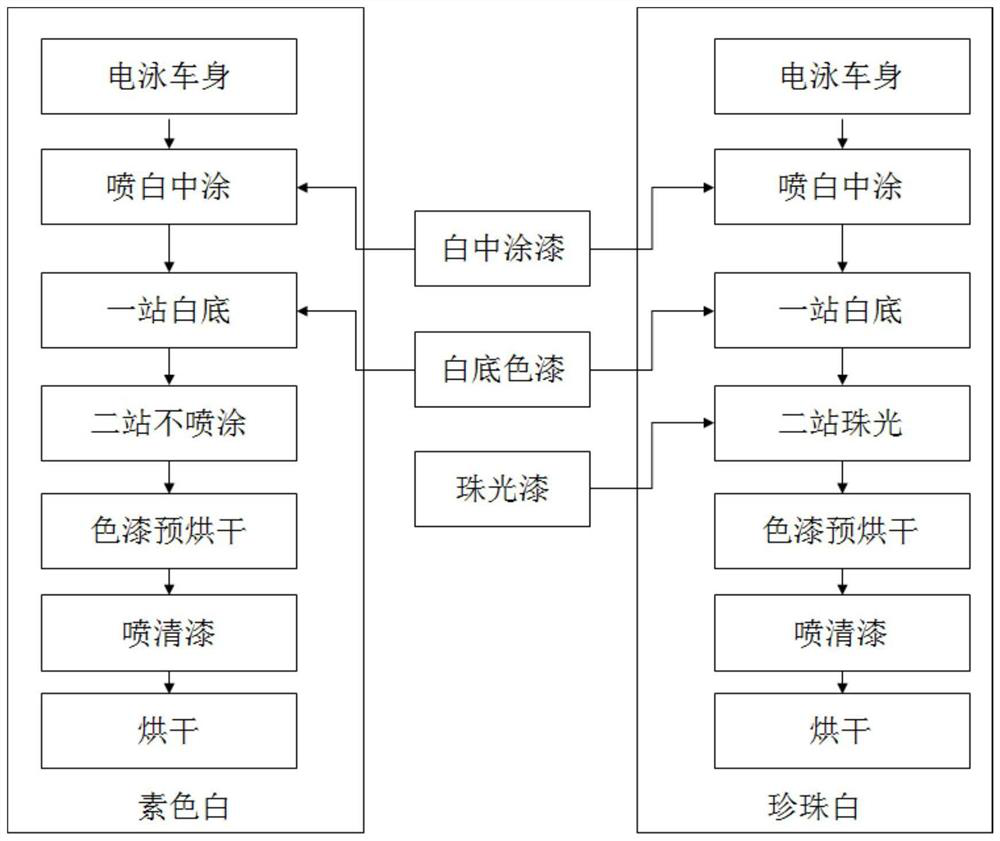

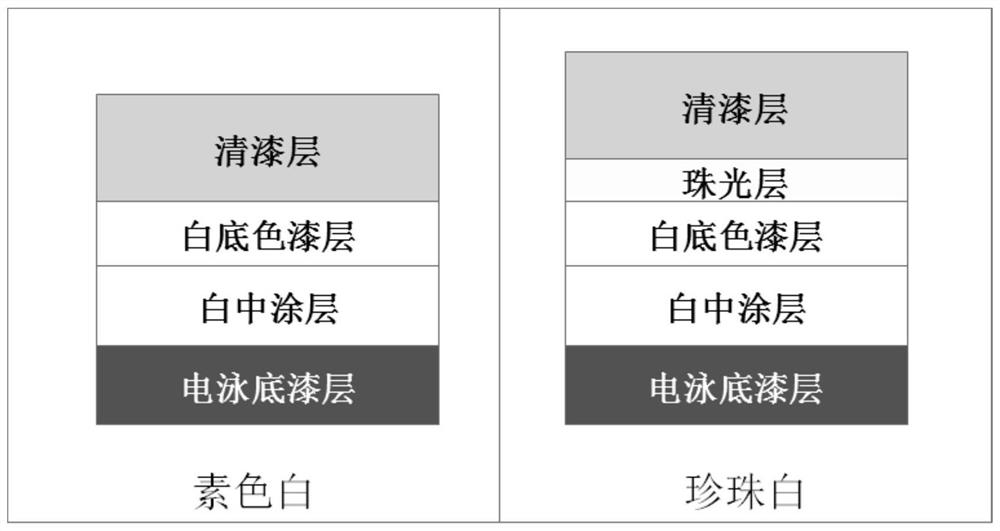

[0027] Such as figure 1 As shown, a kind of automobile spraying method utilizing the color paint sharing system provided by the present invention is as follows: body electrophoresis treatment→spraying white medium paint→spraying white base paint at the first station of the color paint→designing the color according to the body color at the second station of the color paint Selection process: when the design color is pearl white, the robot automatically sprays pearlescent paint; when the design color is plain white, the robot is empty → pre-drying of the color paint → spraying varnish.

[0028] Spraying white medium paint is automatic spraying by robot, using ABB-IRB5500 three manipulators to automatically spray B0 on the outer surface of the car body, the parameters of the spraying machine are set as: paint output 250cc / min, air pressure 7-10kg / cm 2 , The rotating speed of the rotary cup is 40Krpm, the air flow rate of the outer shaper is 400NL / min, and the flow rate of the i...

Embodiment 2

[0035] Such as figure 1 As shown, a kind of automobile spraying method utilizing the color paint sharing system provided by the present invention is as follows: body electrophoresis treatment→spraying white medium paint→spraying white base paint at the first station of the color paint→designing the color according to the body color at the second station of the color paint Selection process: when the design color is pearl white, the robot automatically sprays pearlescent paint; when the design color is plain white, the robot is empty → pre-drying of the color paint → spraying varnish.

[0036] Spraying white paint is automatic spraying by robots. SAMES spraying machine is used to cooperate with three manipulators of Yaskawa robots to automatically spray B0 on the outer surface of the car body. The parameters of spraying machine are set as follows: discharge volume 350cc / min, air pressure 6.0-8.0kg / cm 2 , The rotating speed of the rotary cup is 45Krpm, the air flow rate of the o...

Embodiment 3

[0043] A car spraying method using the color paint sharing system provided by the present invention is as follows: body electrophoresis treatment → spraying white medium paint → spraying white base paint at the first station of the color paint → color selection process according to the design of the car body at the second station of the color paint: When the design color is pearl white, the robot automatically sprays pearlescent paint, and when the design color is plain white, the robot is empty → pre-drying of the color paint → spraying varnish.

[0044] Spraying white medium paint is automatic spraying by robot, using IRB5500 single manipulator to automatically spray B0, spraying machine parameters are set as: output 400cc / min, air pressure 9-10kg / cm 2 , The rotating speed of the rotary cup is 50Krpm, the air flow rate of the outer shaper is 450NL / min, and the flow rate of the inner shaper air is 200NL / min. The paint parameter setting range is: viscosity 650-850mPa.s (viscos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com