A heat sink structure and stamping processing equipment thereof

A technology of stamping processing and cooling fins, applied in metal processing equipment, heat exchange equipment, manufacturing tools, etc., can solve the problems of inability to replace fins, unfavorable maintenance costs of cooling fins, etc., achieve high processing efficiency, convenient replacement, and guaranteed maintenance cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

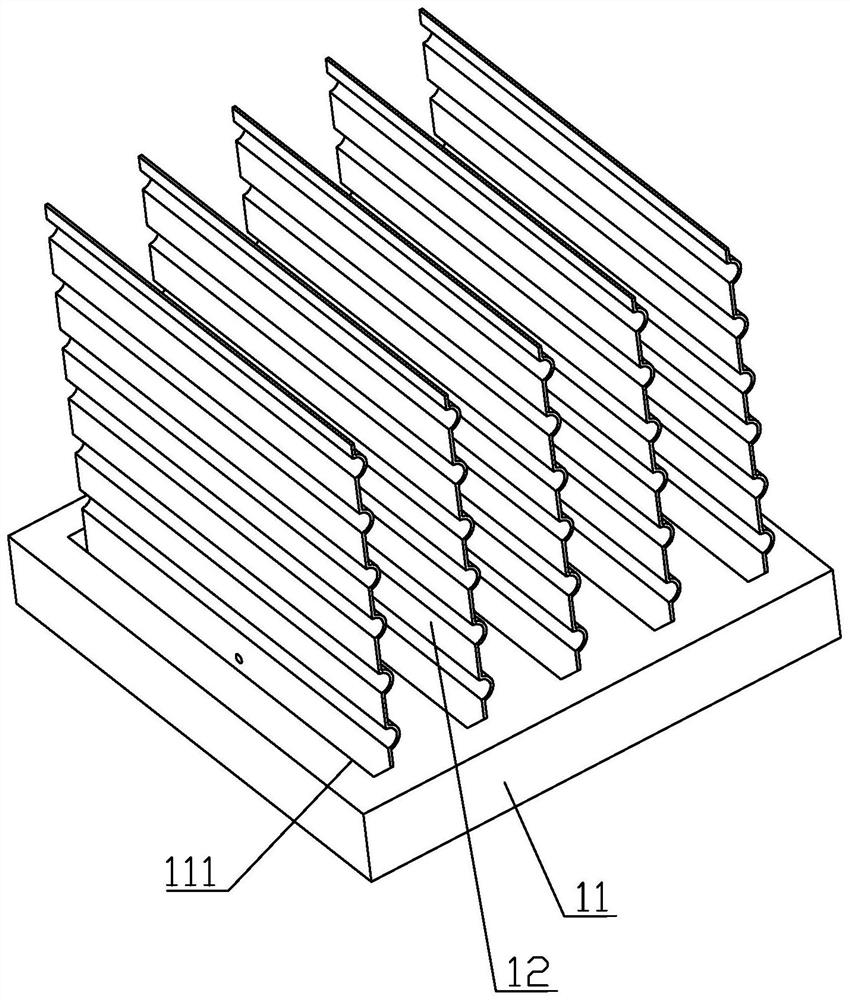

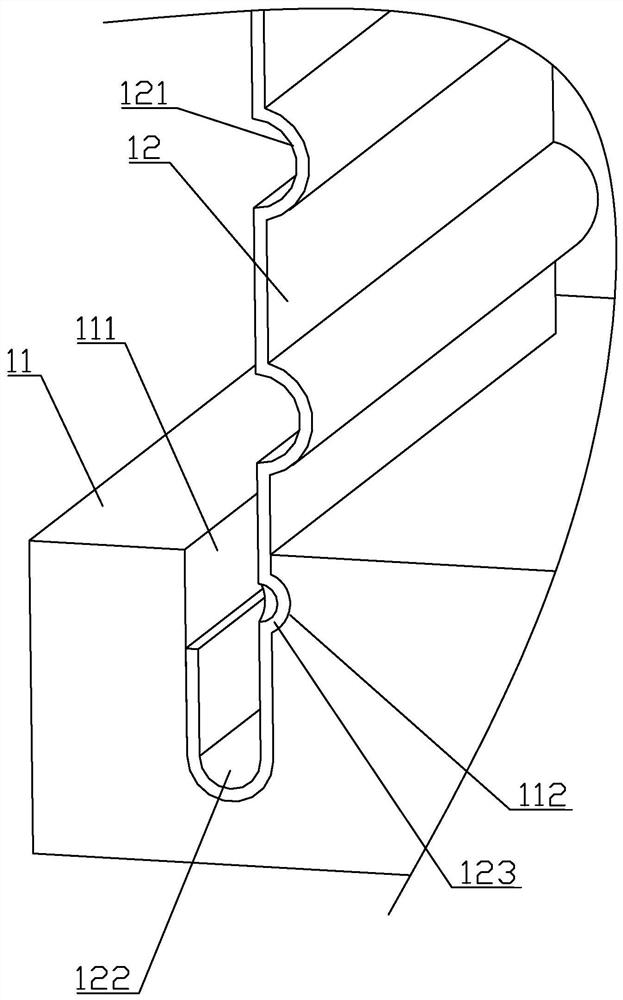

[0035] refer to figure 1 , is a heat sink structure disclosed in the present invention, including a body 11 and a plurality of fins 12 arranged on the body 11 . The main body 11 is in the shape of a rectangular plate, and its length direction is horizontal. The upper surface of the main body 11 is provided with a long slot 111 for insertion. The opening of the long slot 111 is in the shape of a rectangular strip. The direction is vertical, and there are multiple insertion slots 111 , and the insertion slots 111 are evenly arranged along the length direction of the body 11 . to combine figure 2 As shown, one side of the insertion long slot 111 is parallel to the inner side wall of its own length direction and is provided with a snap-in inner slot 112. The inner wall of the snap-in inner slot 112 is arc-shaped, and the opening of the snap-in inner slot 112 is round. shape. The fins 12 are in the shape of a rectangular sheet and are stamped from an aluminum sheet. They are ve...

Embodiment 2

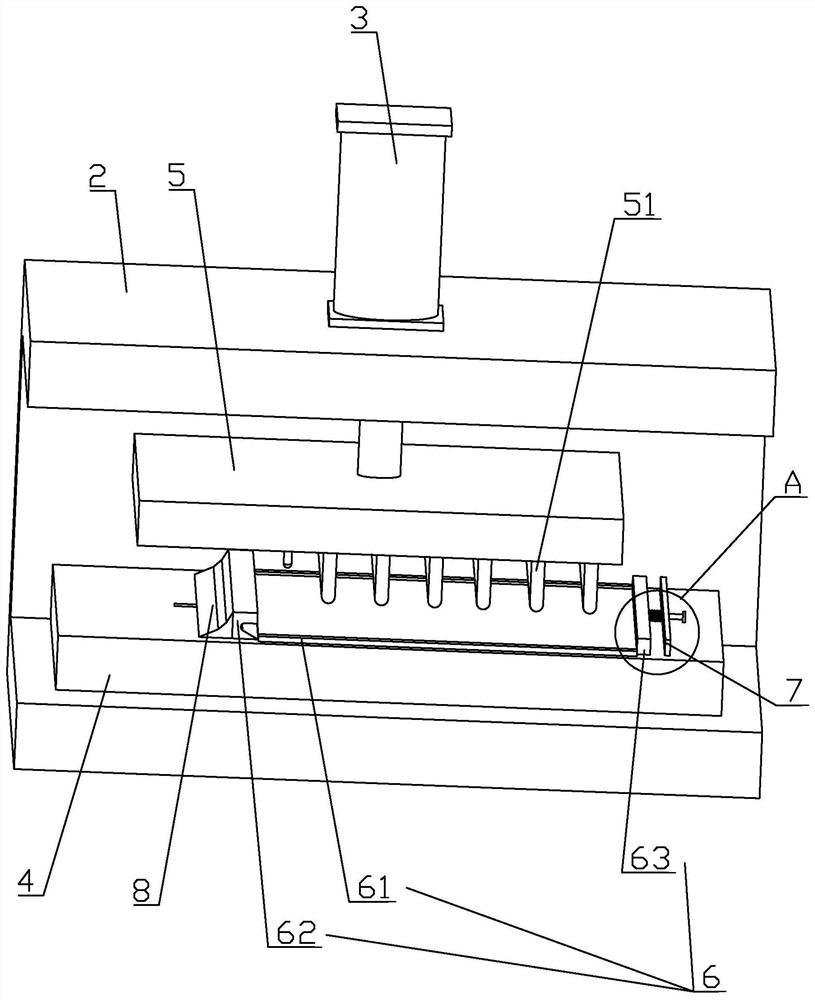

[0039] refer to image 3 , is a heat sink structure stamping processing equipment disclosed in the present invention, including a frame 2, a hydraulic cylinder 3, a workbench 4 and a stamping seat 5, the frame 2 is a frame 2 structure with a U-shaped vertical section, and its The two ends are horizontally facing the same direction, and the hydraulic cylinder 3 is an existing linear drive device. The hydraulic cylinder 3 is arranged on the frame 2 and fixed to the upper surface of the frame 2, and the end of the piston rod of the hydraulic cylinder 3 runs through it vertically and sequentially. The upper surface of the frame 2 and the inner top surface of the frame 2 are also located in the frame 2 . The workbench 4 is a rectangular platform, which is arranged in the frame 2, and the bottom surface of the workbench 4 is fixed to the inner bottom surface of the frame 2. In addition, the workbench 4 is arranged on the lower side of the piston rod end of the hydraulic cylinder 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com