Punch press safety braking device

A technology for safe braking and punching, applied in safety equipment, manufacturing tools, presses, etc., can solve the problems of increasing the number of parts and increasing costs, and achieve the effects of improving safety, avoiding fatigue, and preventing deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

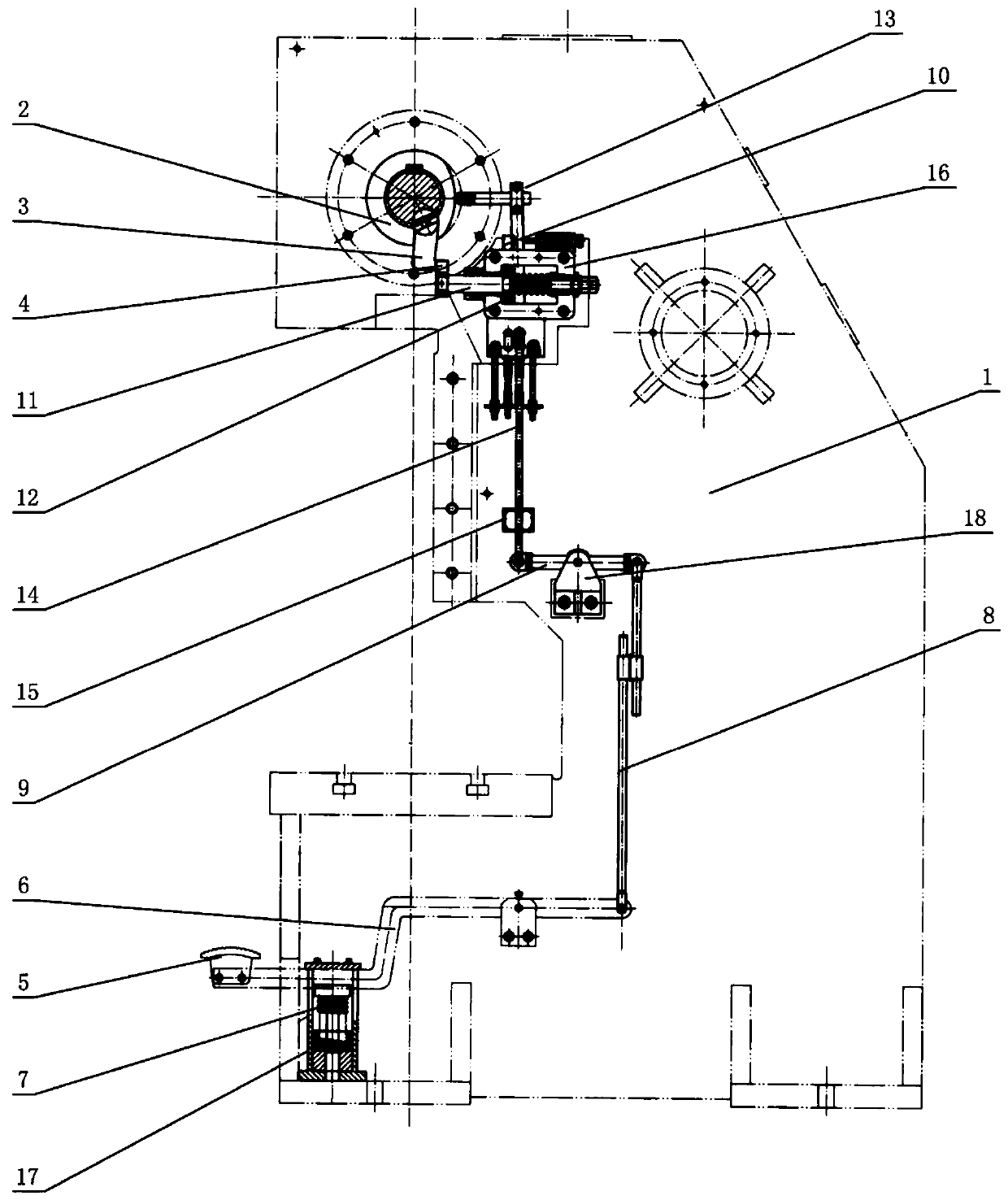

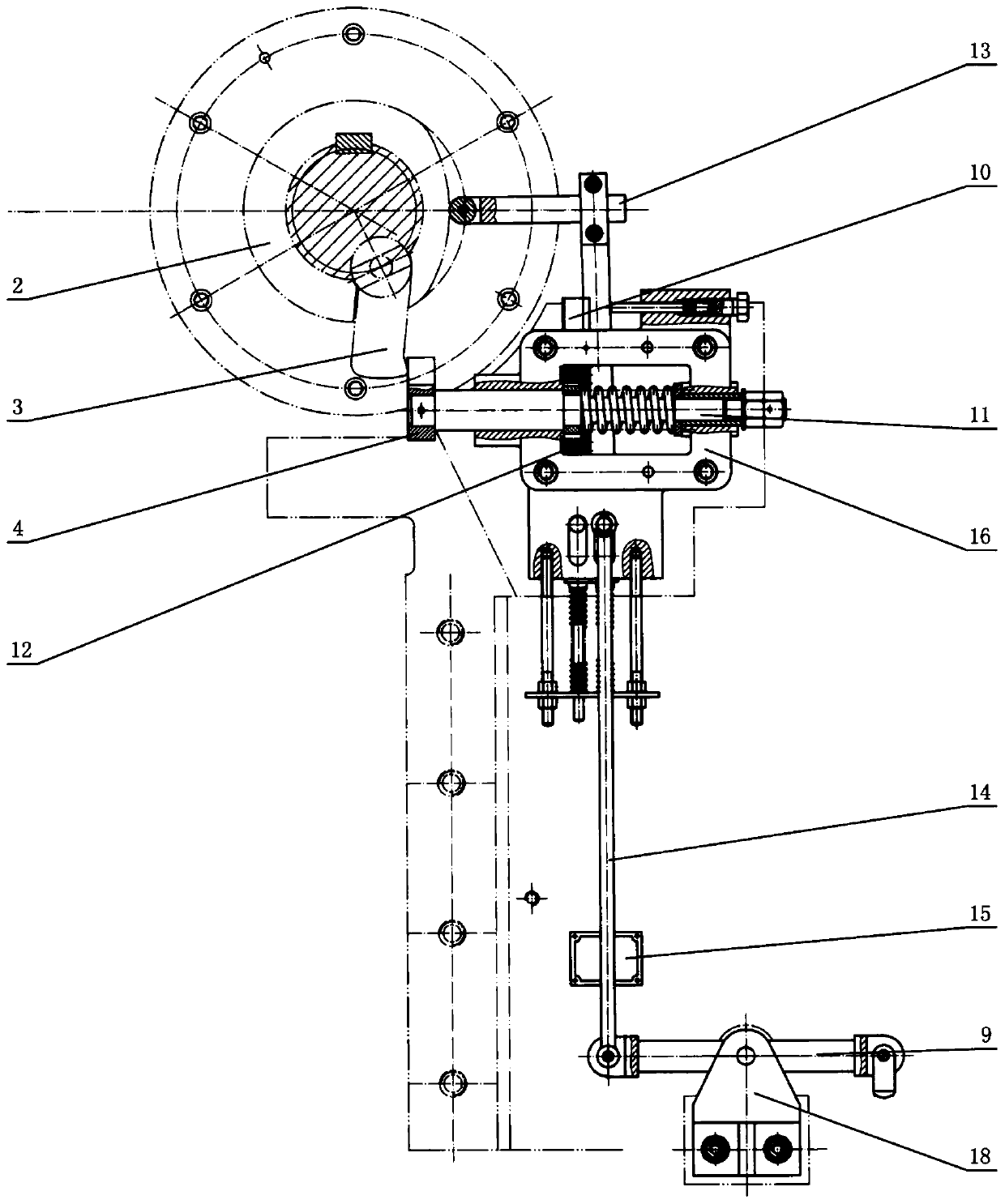

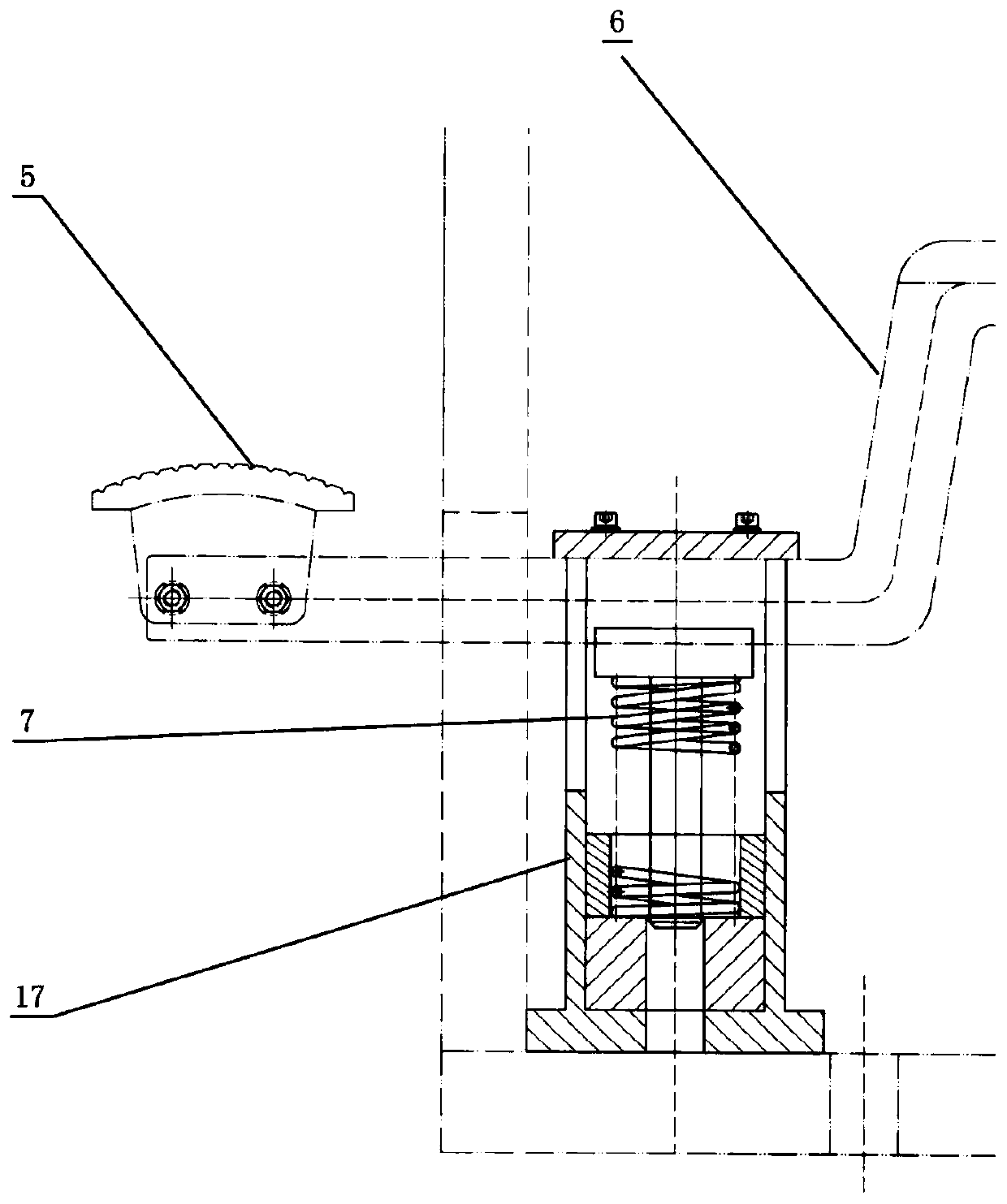

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] see Figure 1-Figure 4 , a safety braking device for a punching machine, the punching machine includes a body 1 and its large gear 2, the large gear 2 runs through a crankshaft, the large gear 2 is provided with a clutch key handle 3, and the side of the body 1 corresponding to the clutch key handle 3 is provided with The retaining wheel 4, the bottom of the fuselage 1 is also provided with a pedal 5, and a transmission fitting is arranged between the pedal 5 and the retaining wheel 4, and the foot pedal 5 controls the rotation of the retaining wheel 4 through the transmission fitting, and the retaining wheel 4 is in rotation Contact the clutch key handle 3 to control the rotation of the crankshaft, so that the slider of the machine tool stops, the stop wheel 4 breaks away from the clutch key handle 3 during rotation, and the clutch is combined t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com