Drilling equipment for heat dissipating plate

A technology for drilling equipment and cooling plates, which is applied in the direction of drilling/drilling equipment, boring/drilling, metal processing equipment, etc. Problems such as distortion of the position where the drill bit contacts, achieve the effect of not being easy to dissipate heat, easy to take out, and convenient to take and place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

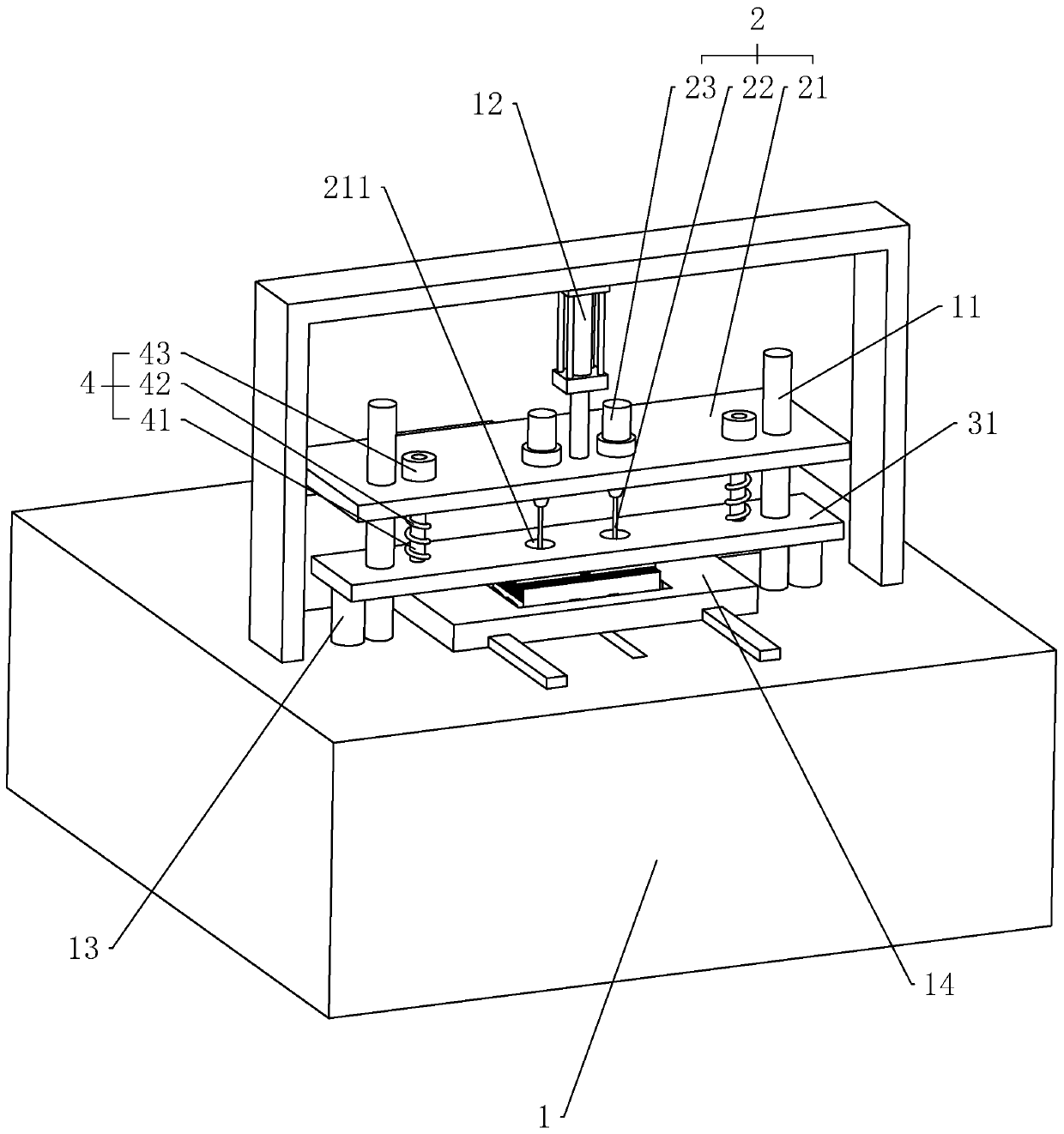

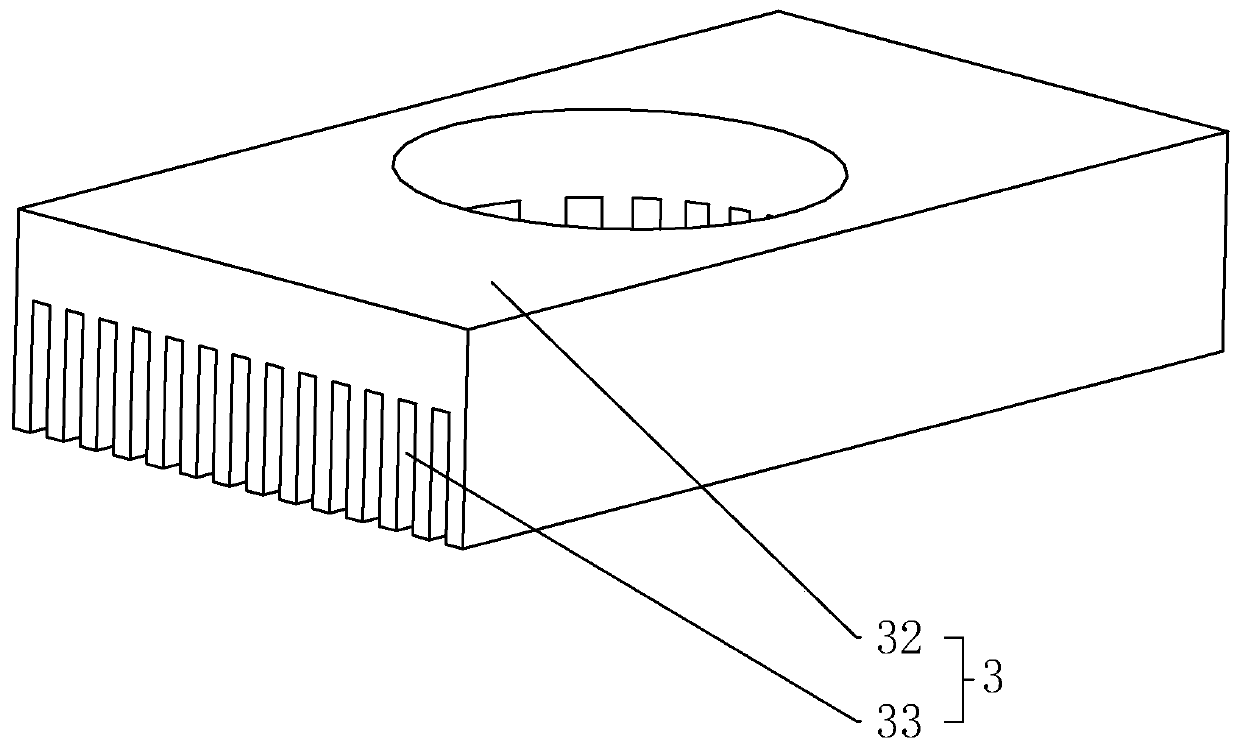

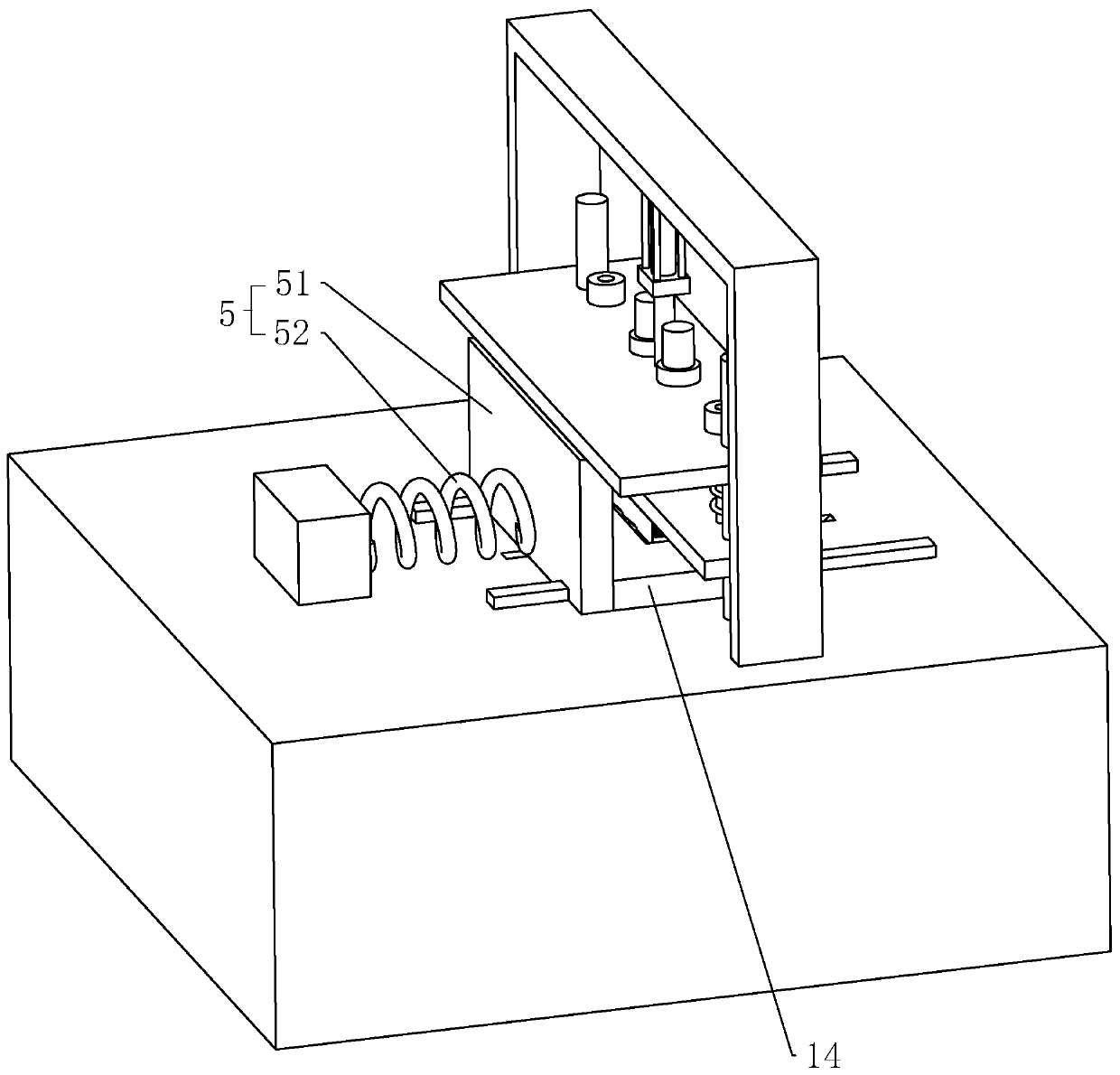

[0034] The invention discloses a cooling plate drilling equipment. When the cooling plate is drilled, the cooling fins connected to the cooling plate will not be twisted, so that the distance between adjacent cooling fins will not change, so that the cooling plate The heat dissipation effect will not be affected. like figure 1 As shown, it includes a frame body 1, a drilling mechanism 2 connected to the frame body 1, and a positioning mechanism 3 for positioning the heat sink. The drilling mechanism 2 includes a sliding base 21 that slides vertically along the frame body 1, two drill bits 22 that are rotatably connected to the lower end of the sliding base 21, and a motor 23 that drives the two drill bits 22 to rotate respectively. Both motors 23 are fixed with a reducer by bolts, and the reducer is fixed on the upper end of the sliding seat 21 by bolts. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com