A high-speed and stable tower type boring and milling machining center

A kind of boring and milling processing and stable technology, which is applied in the field of high-speed and stable tower boring and milling machining centers, can solve the problems of affecting the machining accuracy, instability, and large torque of the rotating shaft, so as to avoid machining accuracy, reduce internal wear, and reduce The effect of small torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

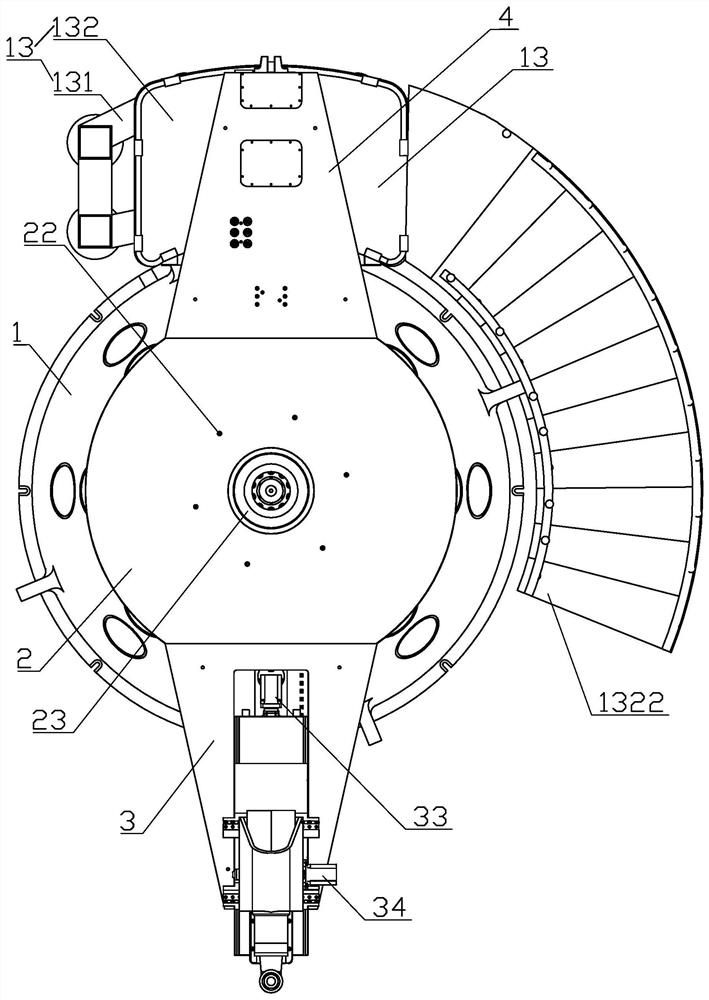

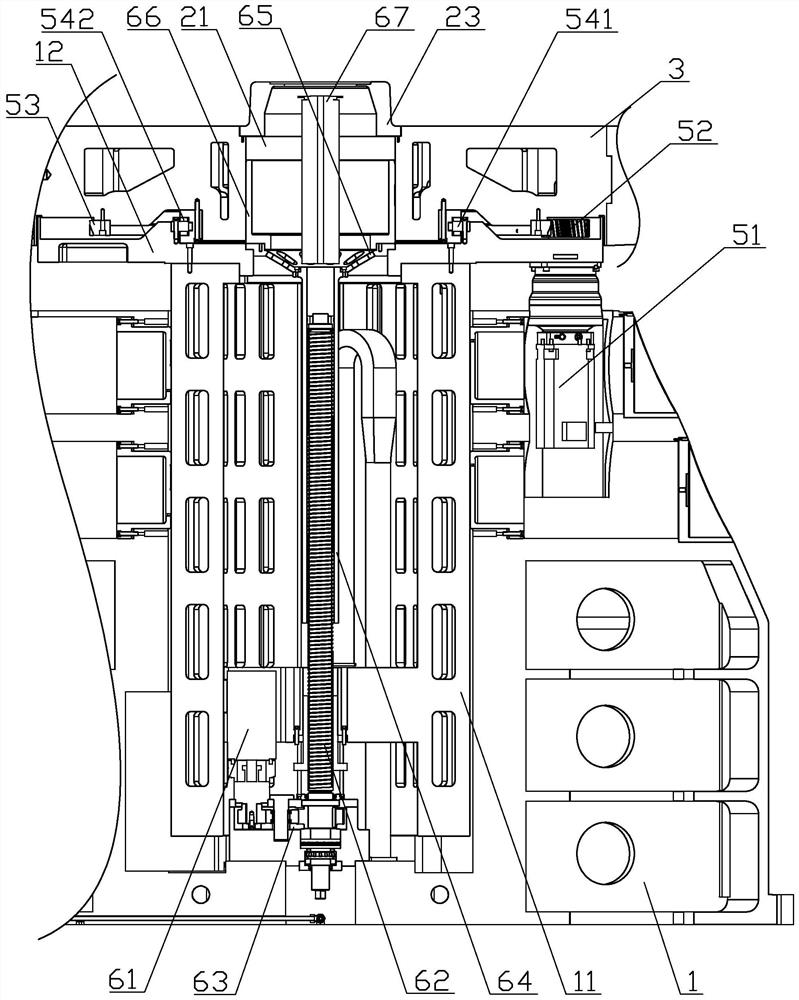

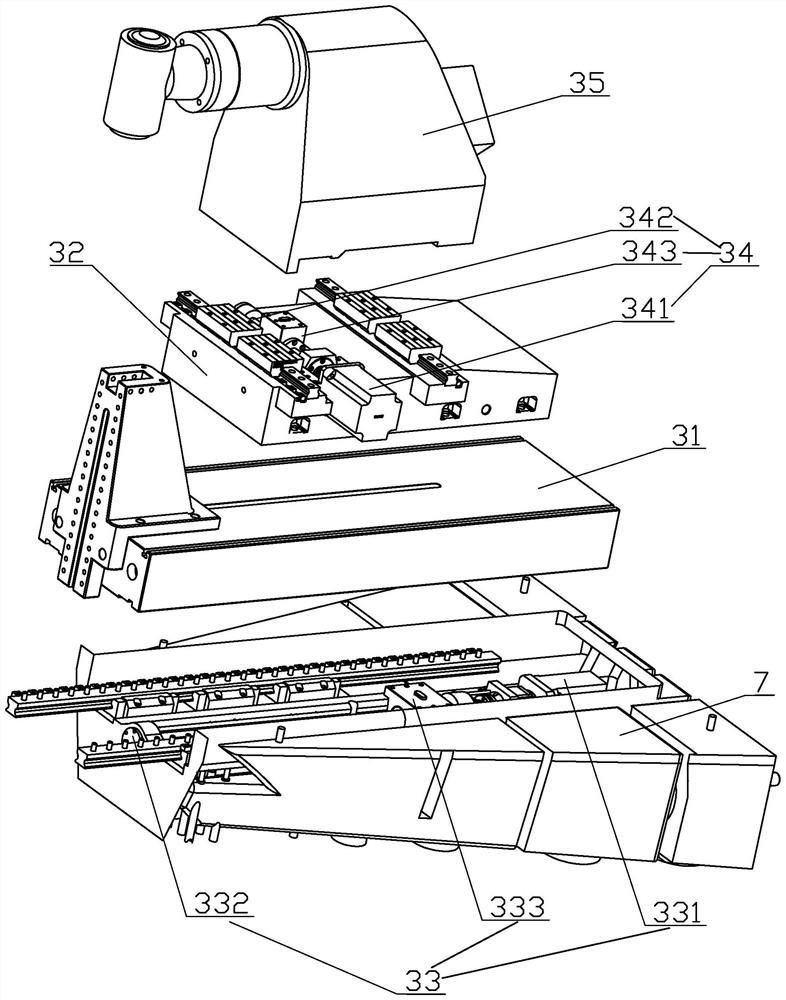

[0039] like figure 1 As shown, it is a high-speed and stable tower type boring and milling machining center disclosed by the present invention, including a base warehouse 1, a turntable 2 and a controller (not shown); combined figure 2 As shown, the base bin seat 1 is tower-shaped, and there is a hollow cavity inside, and a central cylinder 11 is arranged in the cavity. . A bearing seat 12 is arranged on the top of the central cylinder 11, and the bearing seat 12 is an annular disk-shaped structure, and the turntable 2 is rotatably mounted on the bearing seat 12. The cross-section of the turntable 2 is ring-shaped, and two symmetrical sections are arranged on its periphery. The left cutting arm 3 and the right cutting arm 4 are respectively fixed on the two sections, and the left cutting arm 3 and the right cutting arm 4 are equipped with The tool; as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com