Pressing ceramic die and ceramic blank manufacturing method

A technology of ceramic moulds, ceramics, applied in the direction of moulds, manufacturing tools, ceramic molding machines, etc., can solve the problems of shortened production cycle, longer production cycle, high production cost of a single piece of ceramics, to reduce production costs, rough surface The effect of good degree and dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

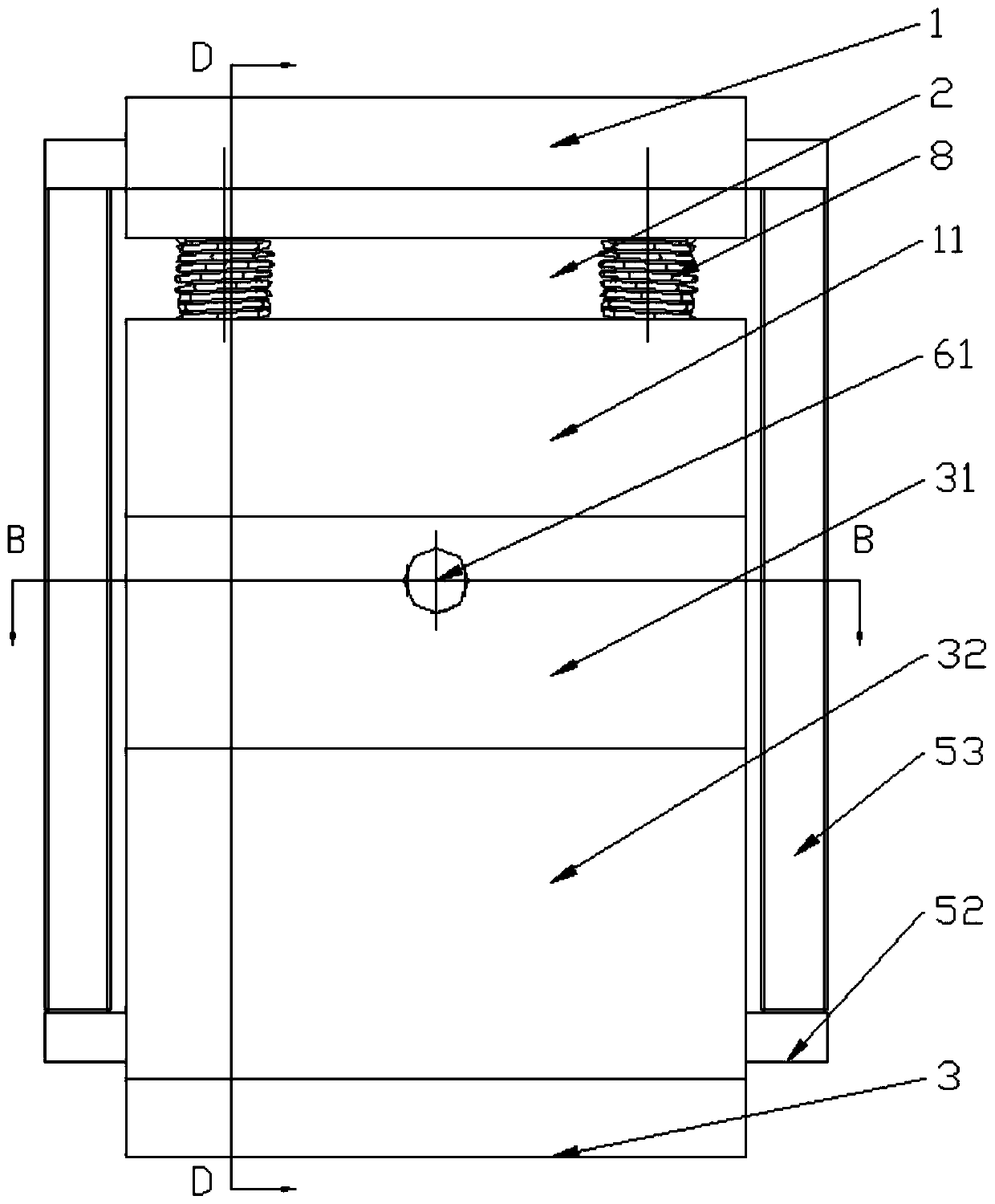

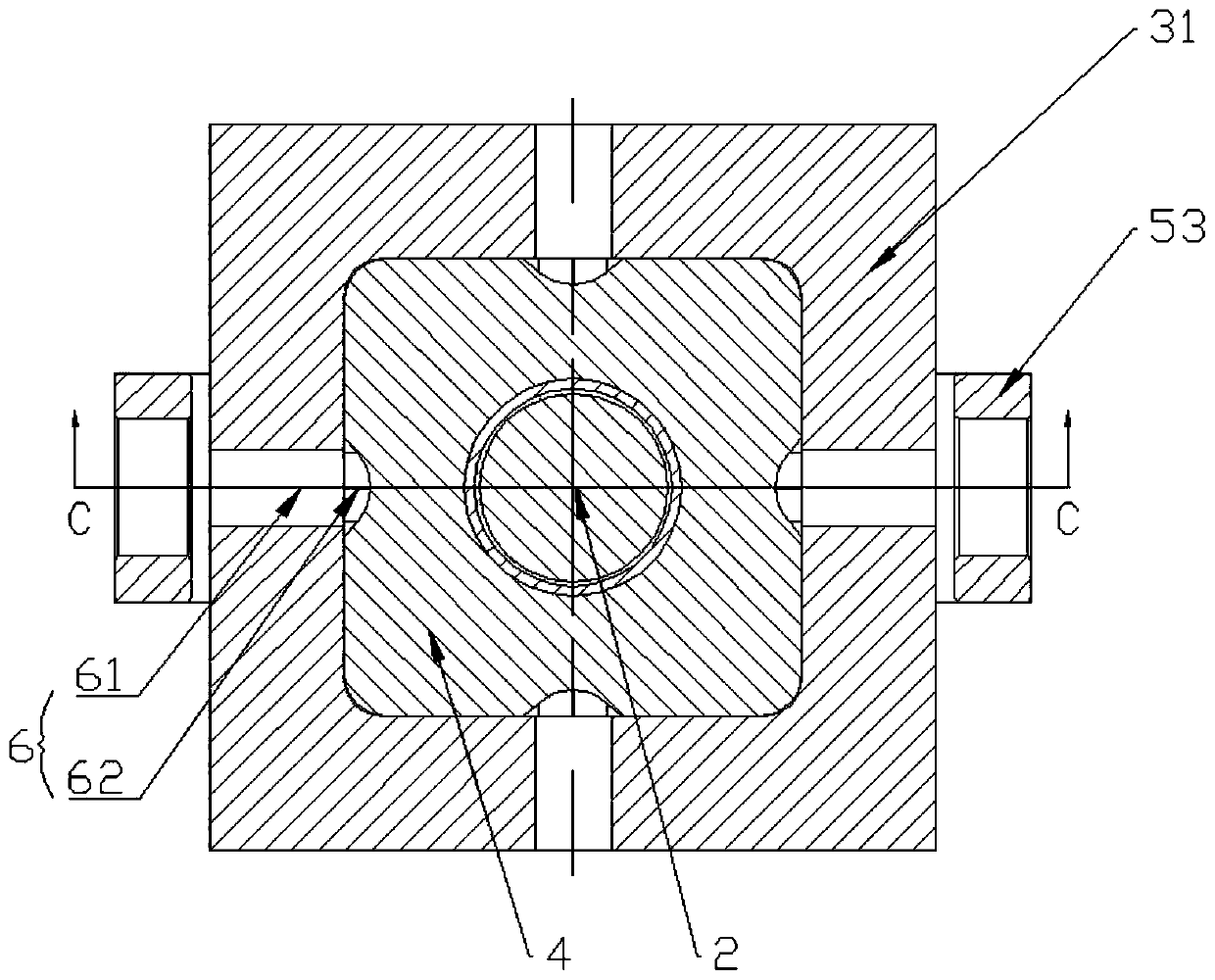

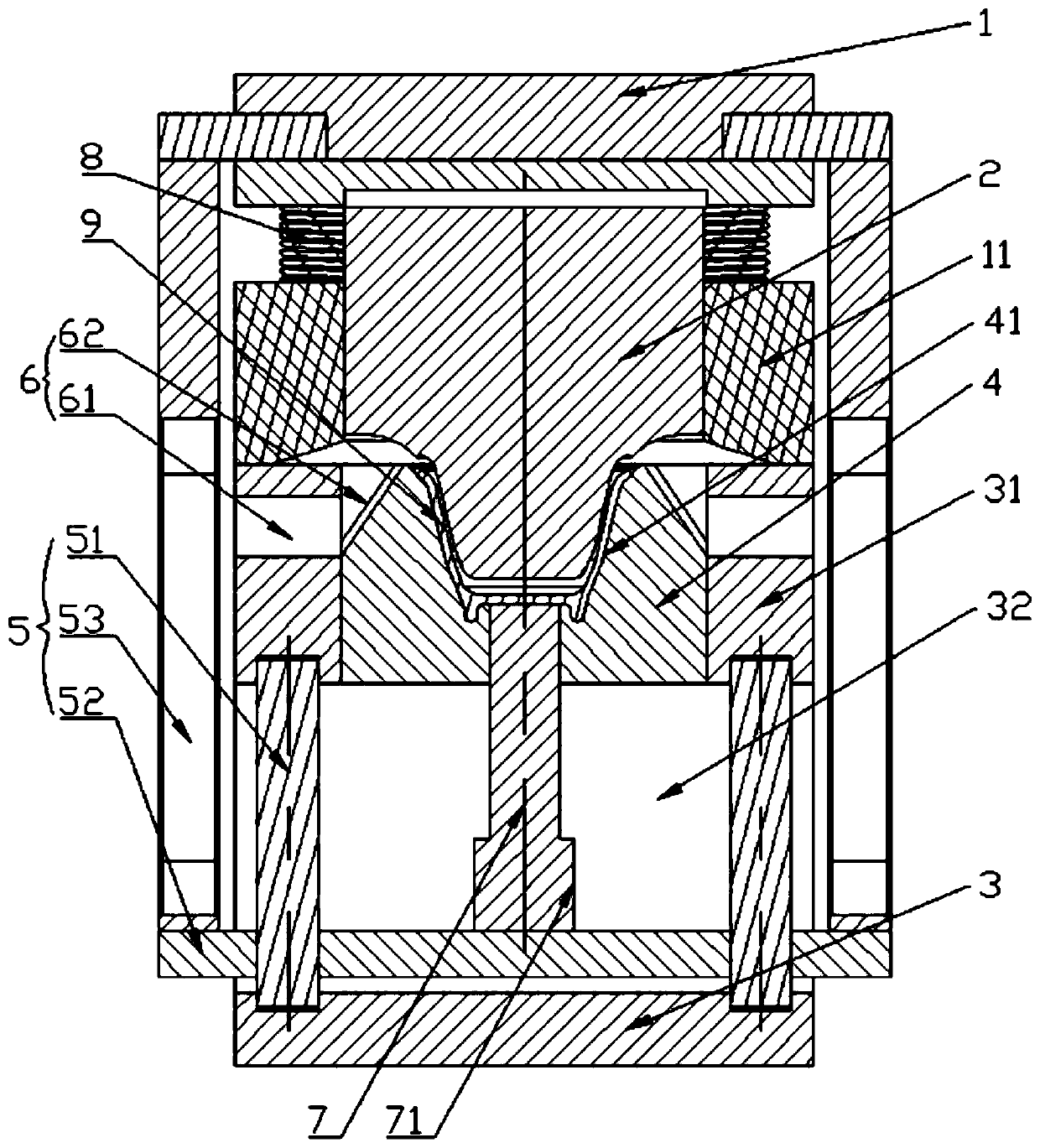

[0040] Such as Figure 1 to Figure 4 Shown:

[0041] A compacting ceramic mold provided in this embodiment includes: an upper mold fixing plate 1, a punch 2, a lower mold fixing plate 3, a lower mold module 4, and a guide pillar structure 5. The upper mold fixing plate 1 is located on the top of the ceramic pressing mold, the punch 2 is fixed to the bottom of the upper mold fixing plate 1 through the upper connecting block 11, the punch 2 is fitted into the through hole in the center of the upper connecting block 11, and the upper connecting block 11 The surface is connected to the upper die fixing plate 1 through a connecting rod, the upper end of the punch 2 is in sliding fit with the groove on the lower surface of the upper die fixing plate 1, and the punching part of the punch 2 (the part that directly presses the ceramic material) The shape of the pressed ceramic part 9 (open vessel, such as tea cup, bowl, etc.) is consistent with the inner cavity structure. The lower mold...

Embodiment 2

[0049] According to another aspect of the present invention, a method for manufacturing a ceramic blank is disclosed, including the following steps:

[0050] S1. Preparation of ceramic raw materials with a water content of 3.5% to 5.5%;

[0051] S2. Add a certain amount of the above-mentioned ceramic raw material with a water content of 3.5% to 5.5% into the pressing groove 41 of the pressing ceramic mold;

[0052] S3. The punch 2 presses down the ceramic material to form a ceramic embryo;

[0053] S4. After the pressing is completed, the mold is opened to take out the pressed ceramic embryo;

[0054] S5. Put the pressed ceramic blanks into a calcining furnace for calcination, and cool the ceramic blanks after the calcination is completed.

[0055] Among them, the solid content of the ceramic raw materials is: clay 10%-20%, quartz 15%-23%, feldspar 5%-8%, aged clay 13%-16%, sericite 5%-6%, talc 6 %-7%, Lime 13%-15%, MgO1%-1.5%, ZnO1%-1.5%, BaO1.5%-1.2%, Cr2O31%-1.2%, SiC1%-1.2%, Si3N40....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com