Ambient temperature control device and method for thermal environment test of attitude control engine

An ambient temperature and control device technology, applied in rocket engine devices, machines/engines, jet propulsion devices, etc., can solve the problems of long vacuuming time, poor cooling and cooling effect, and non-directional heat radiation, so as to avoid the power supply system. Short circuit problem, uniform cooling, and the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The following Examples and drawings of the present invention, the technical solutions of the present invention are clearly and completely described, obviously, not to limit the described embodiment of the present invention.

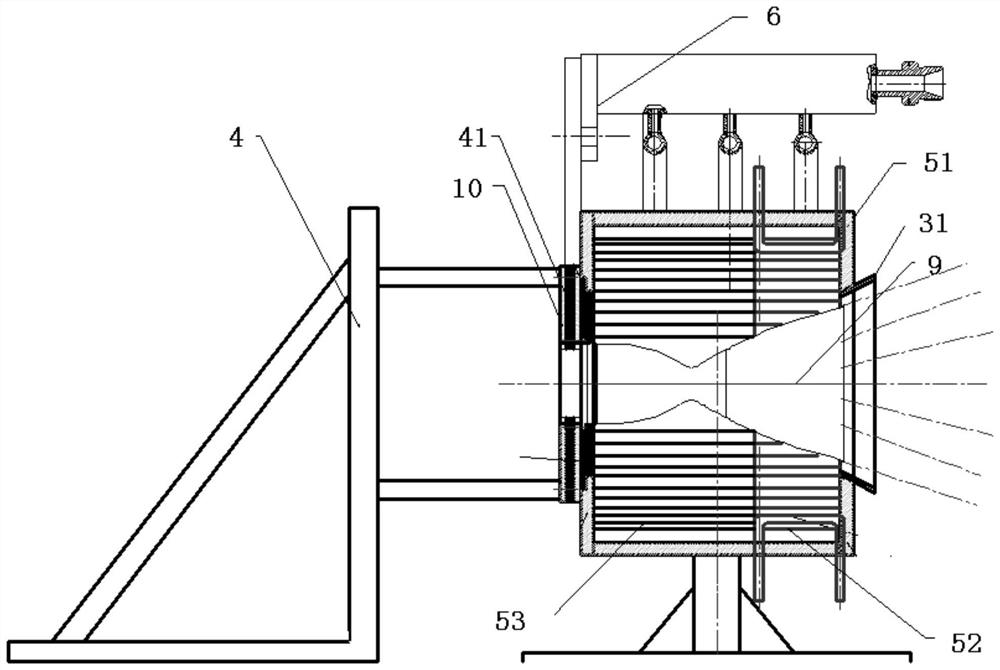

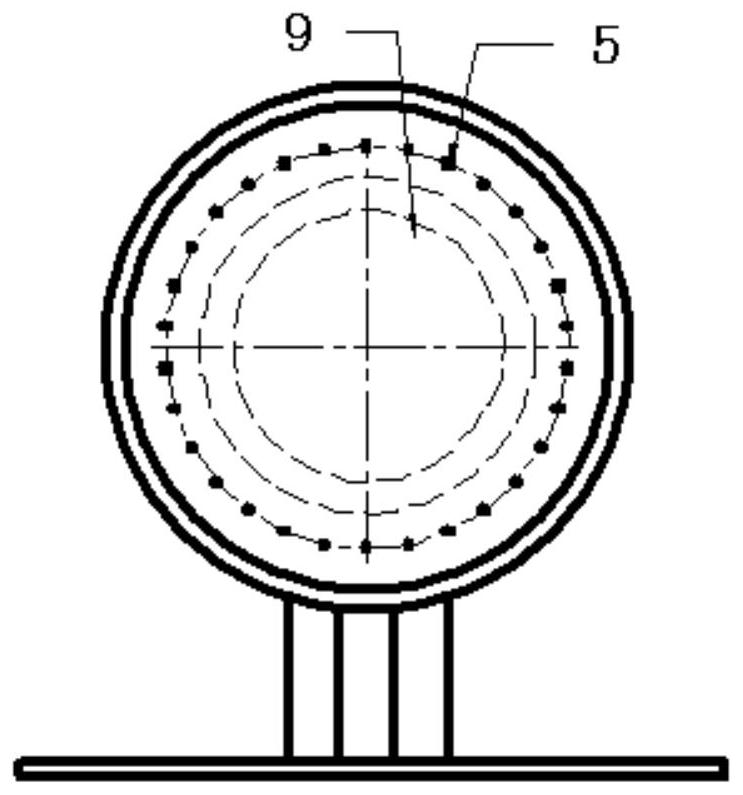

[0056] Attitude control engine thermal environment test in the present embodiment the temperature control apparatus comprises a vacuum chamber 1, a low temperature vacuum chamber assembly 2, the exhaust assembly 3, the engine support frame 4 is fixed, the lamp array assembly 5, 6 water-cooled components, vacuum 7 system and a nitrogen blowing assembly 8;

[0057] Such as figure 1 , figure 2 and image 3 , The engine support frame 4 is fixed in the vacuum chamber 1 is provided, for fixing the attitude control test engine 9;

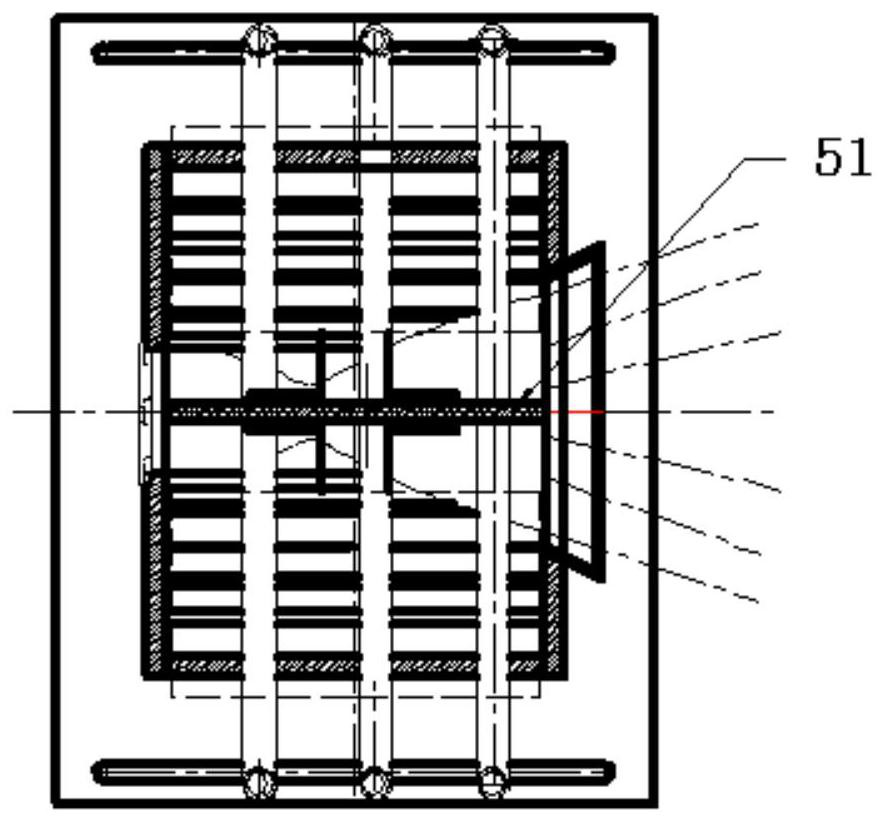

[0058] The lamp assembly array 5 through the stationary platen 4 is fixed to the engine stationary support frame 10;

[0059] The lamp assembly 5 comprises a matrix array of light frame 51 is provided on the frame 51 of the lamp arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com