Heat Flux Test Method for Attitude Control Engine in Vacuum Environment

A technology of heat flux density and vacuum environment, which is applied in the direction of machines/engines, rocket engine devices, mechanical equipment, etc., can solve problems such as unstable propellant supply, long vacuuming time, and large error in heat flux loading, so as to ensure constant heat flow Density requirements, extended service life, and the effect of precise loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention and the accompanying drawings. Apparently, the described embodiments do not limit the present invention.

[0057] A kind of heat flux heat test method in the vacuum environment of attitude control engine in the present embodiment, comprises the following steps:

[0058] Step 1 Installation of thermal environment device

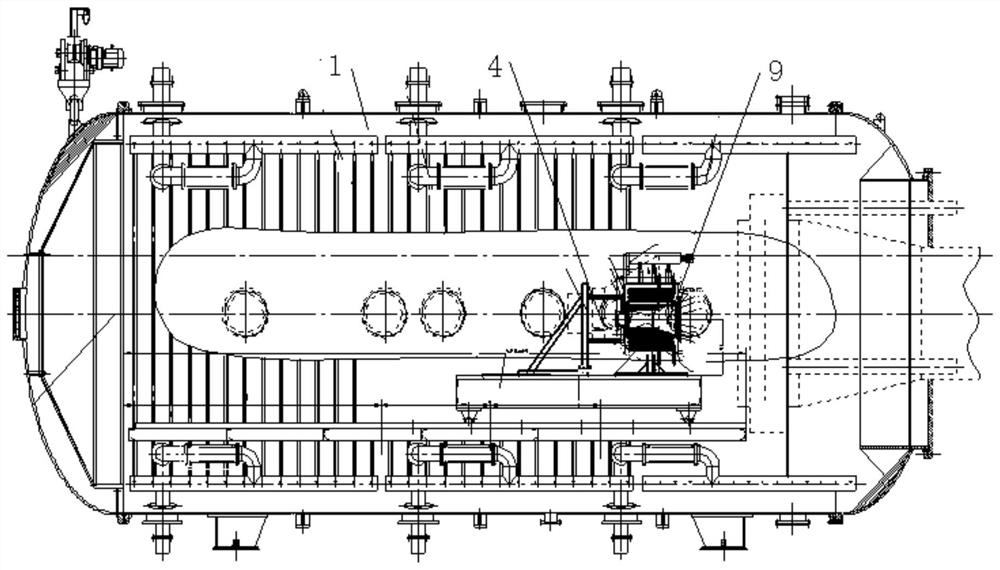

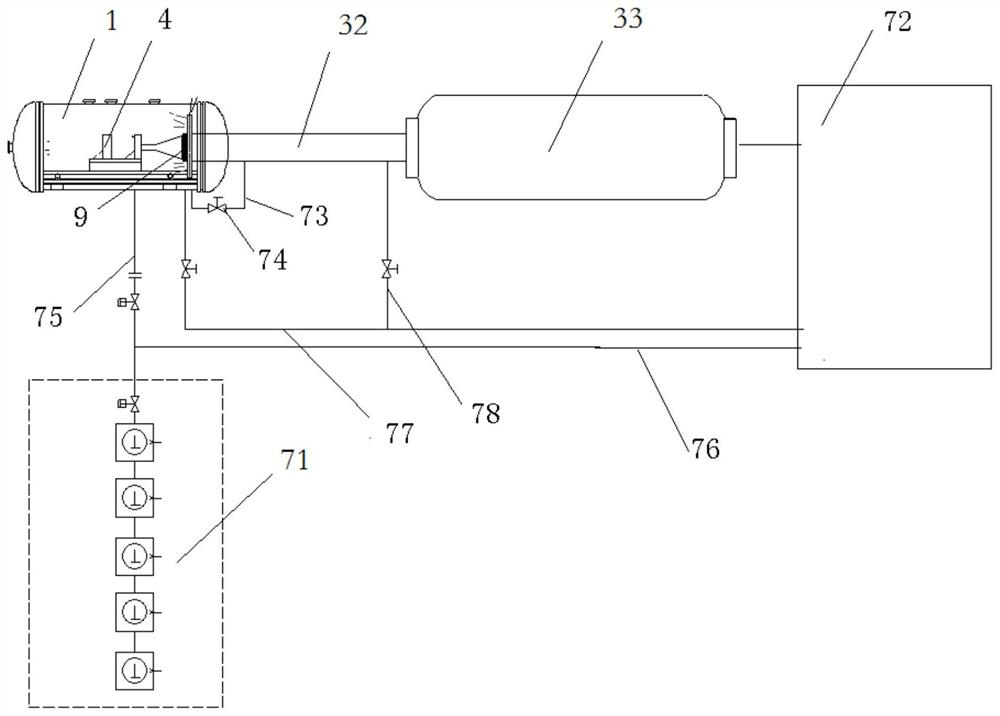

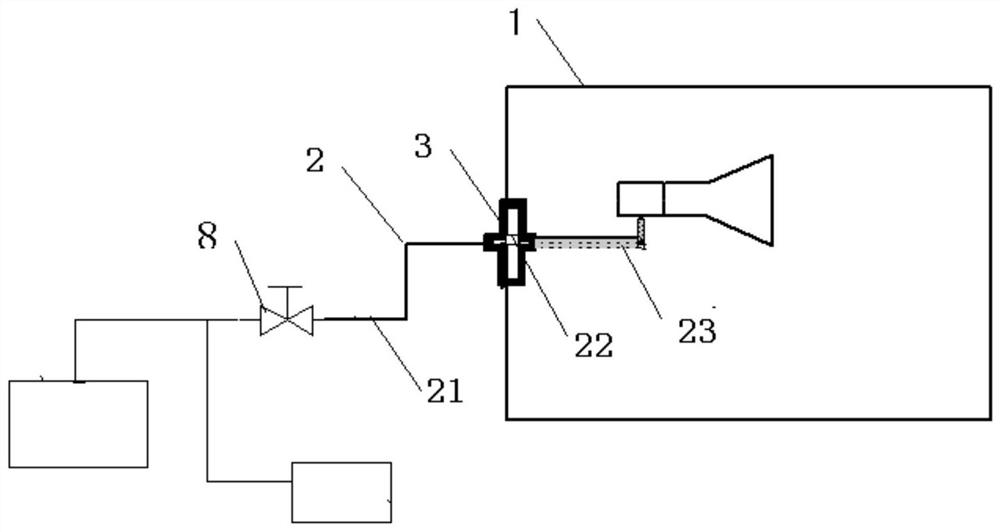

[0059] Step 1.1 as in figure 1 As shown, the attitude control engine simulation part 9 is installed in the vacuum chamber 1 through the fixed support frame 4; the attitude control engine simulation part 9 is divided into a body heat flow loading area and a nozzle tail heat flow loading area, and both heat flow loading areas are installed with The heating lamp array and the heat flow meter group; each heating lamp array is installed in the corresponding heat flow loading area through the lamp array ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com