Physical yarn parting equipment for textile biological fiber surface treatment

A biological fiber and surface treatment technology, which is applied in the processing of textile materials, equipment configuration for processing textile materials, liquid/gas/steam textile material processing, etc., can solve problems affecting processing quality and efficiency, brittleness, damage, etc., to achieve Uniform and thorough surface treatment, prevent sticking and carbonization, and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

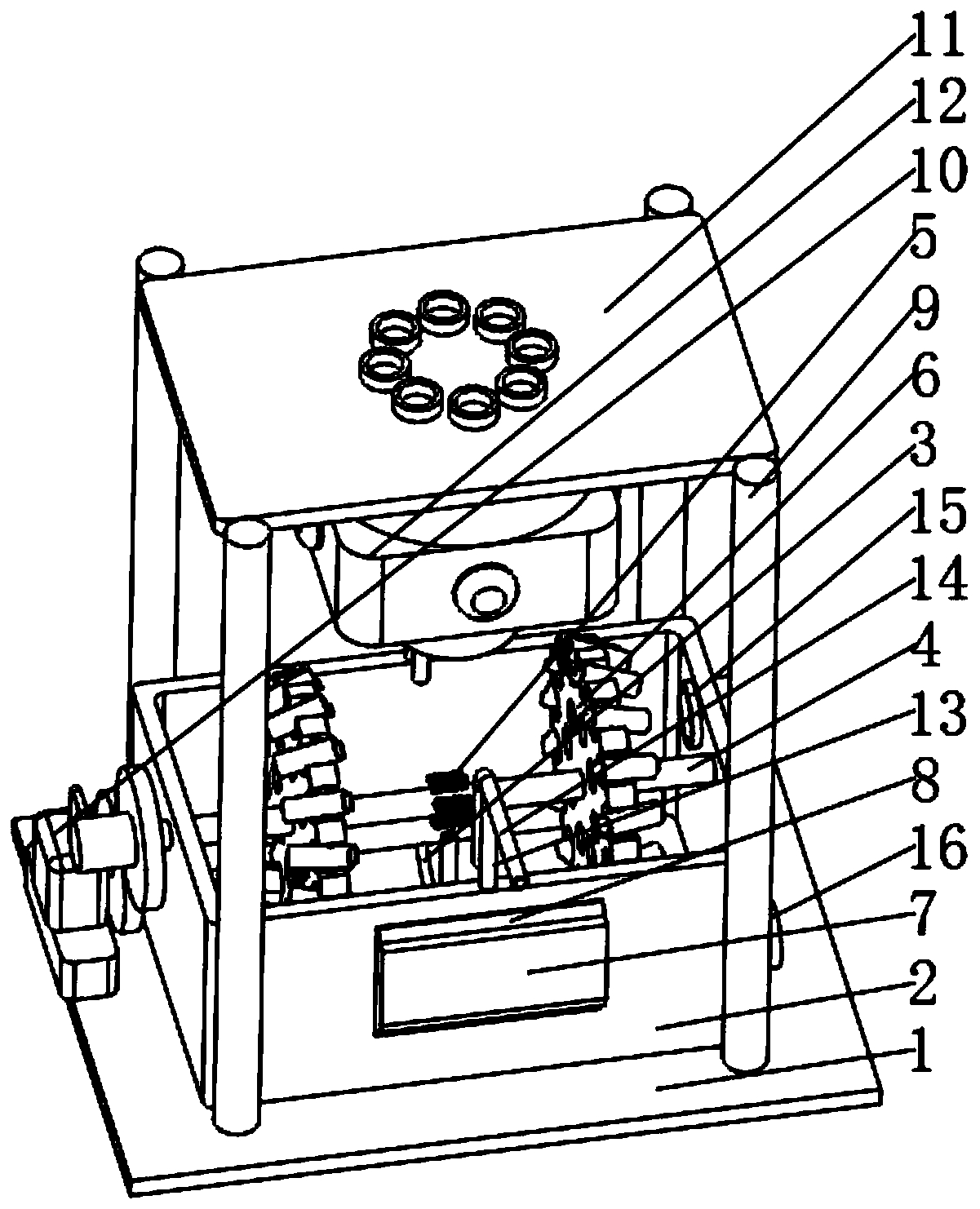

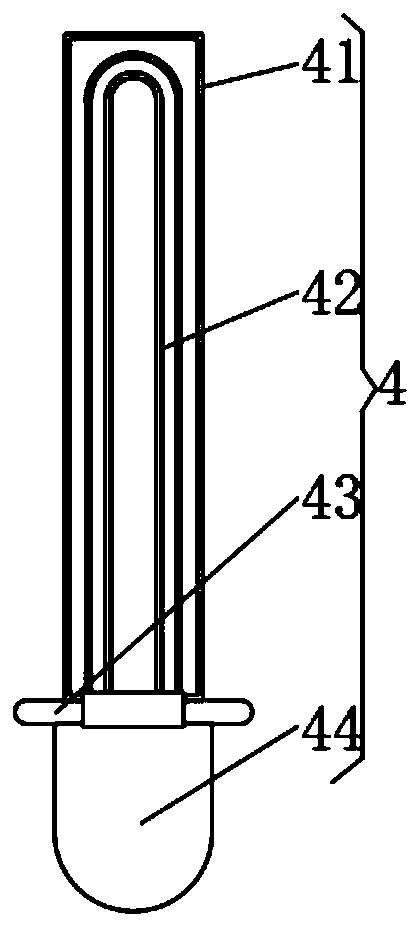

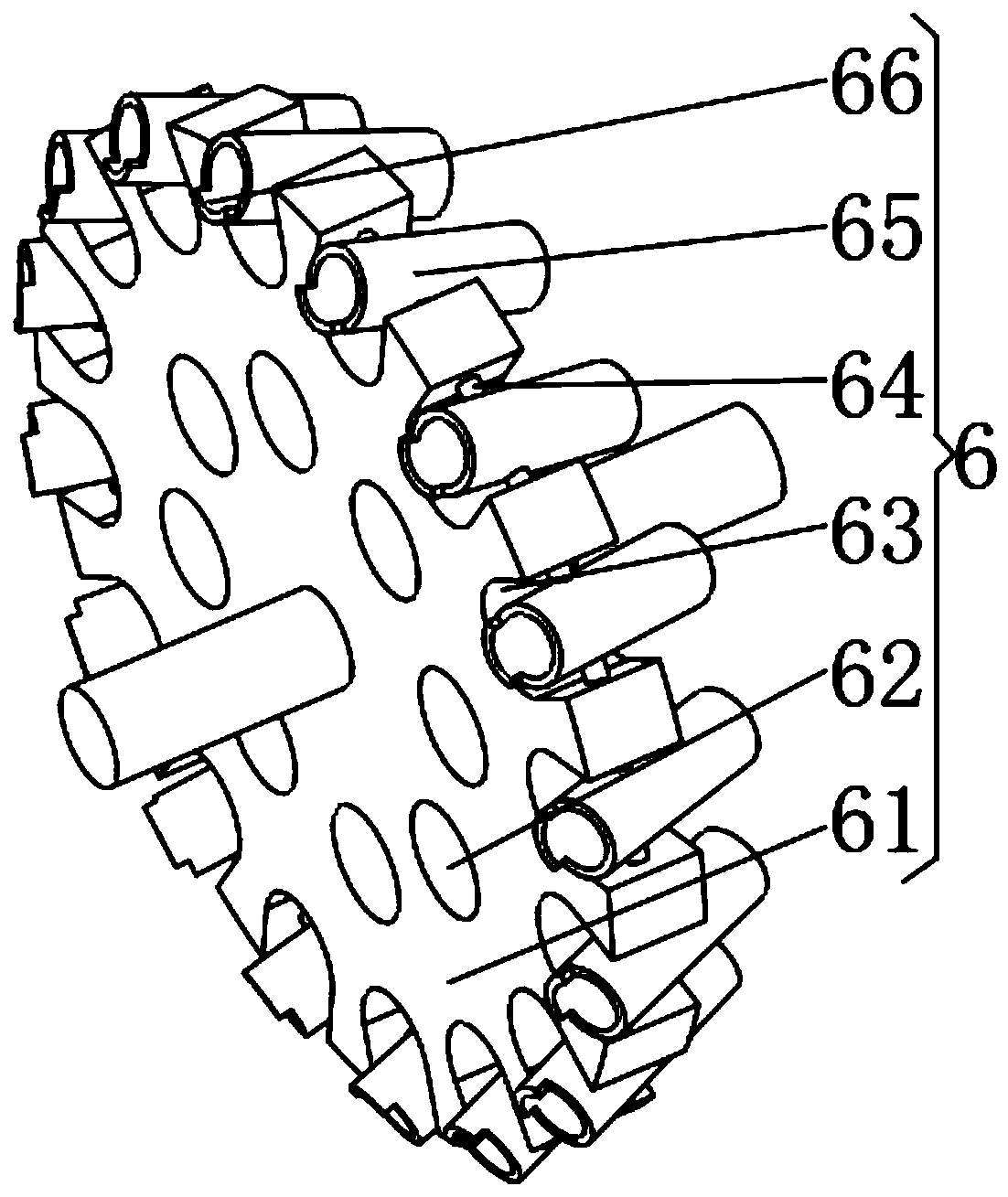

[0035] see Figure 1-4, the present invention provides a technical solution: a physical branching device for textile biological fiber surface treatment, comprising a base plate 1, a treatment box 2 is fixedly connected to the middle position of the top of the base plate 1, and the middle position of the bottom of the inner cavity of the treatment box 2 is fixedly connected There is a conduit 3, and the middle position of the inner wall on both sides of the treatment box 2 is rotatably connected with a turning mechanism 4, and the middle position of the outer surface of the turning mechanism 4 is fixedly connected with a carding brush 5, and the outer surface of the turning mechanism 4 is fixedly connected with a processing mechanism on both sides of the carding brush 5 6. The front and back of the processing box 2 are fixedly connected with a card holder 7, and the inner cavity of the card holder 7 is movably connected with a permanent magnet 8. The top of the base plate 1 is l...

Embodiment 2

[0046] see Figure 1-5 On the basis of Embodiment 1, the present invention provides a technical solution: the branching mechanism 12 includes an outlet barrel 121, the bottom of the outlet barrel 121 is connected with a negative pressure fan 122, and the end of the negative pressure fan 122 away from the outlet barrel 121 is fixedly connected to a Into the wire barrel 123.

[0047] When in use, in the above-mentioned working process, start the negative pressure fan 122 to suck the textile fibers, so that the textile fibers do not need to provide kinetic energy, and the textile fibers are sucked and driven by negative pressure, and dried by air flow, so that the processed The liquid dries and falls off, avoiding the impact on subsequent processing, and providing power to avoid energy waste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com