High-temperature air molten salt heat exchanger

A high-temperature air and heat exchanger technology, applied in the field of high-temperature waste heat recovery, can solve the problems of low efficiency and high energy consumption, and achieve the effects of improving heating efficiency, improving heat exchange efficiency, and strengthening heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

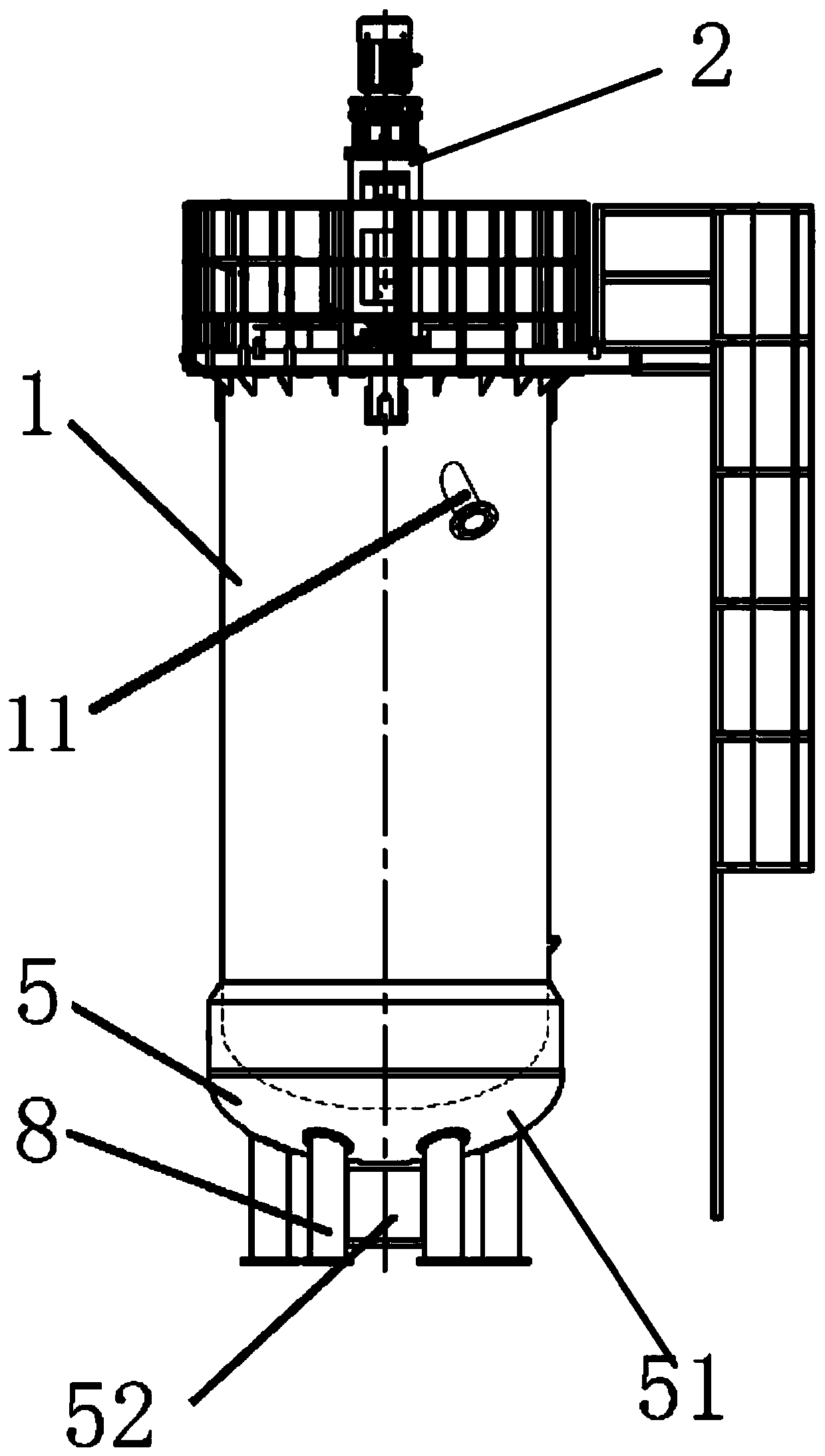

[0034] The existing molten salt heat exchange device is a shell and tube type, see Figure 8 . The existing melting heat exchange device uses the heat of high-heat gas such as high-temperature tail gas generated in the industry to raise the temperature of the molten salt, thereby meeting the heating demand of the molten salt and making full use of the heat in the industrial tail gas.

[0035] Because the flow rate of molten salt is determined by the feed rate of molten salt. If the flow rate is too high, the heat exchange efficiency between the molten salt and the heat exchange tube will not be high, which not only affects the heating effect of the molten salt, but also has low utilization efficiency for the heat of the gas. If the flow rate is too slow, it is easy to cause the salt temperature to be too high, which will cause the molten salt to decompose.

[0036] Moreover, the existing molten salt heat exchange devices are often set Figure 8 The baffle plate marked A in . ...

Embodiment 2

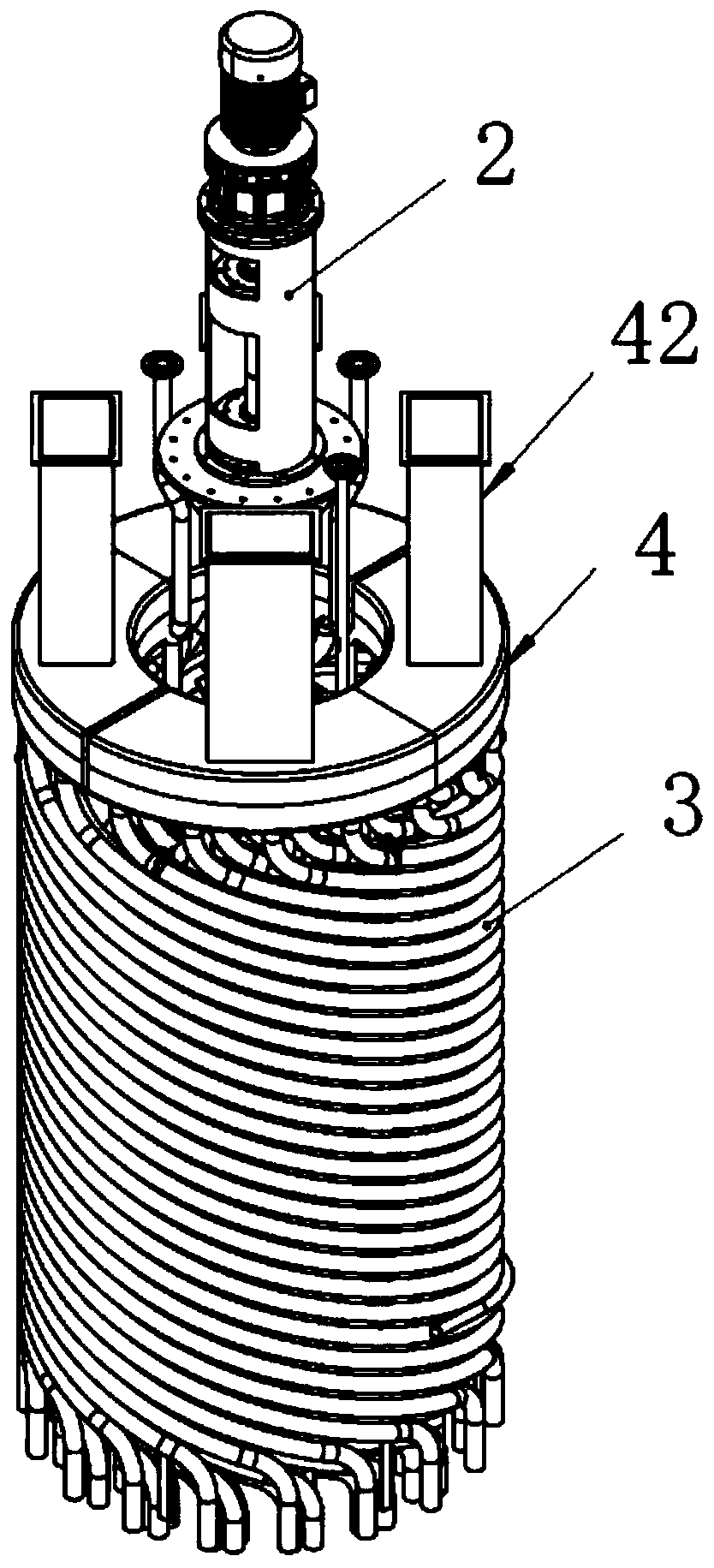

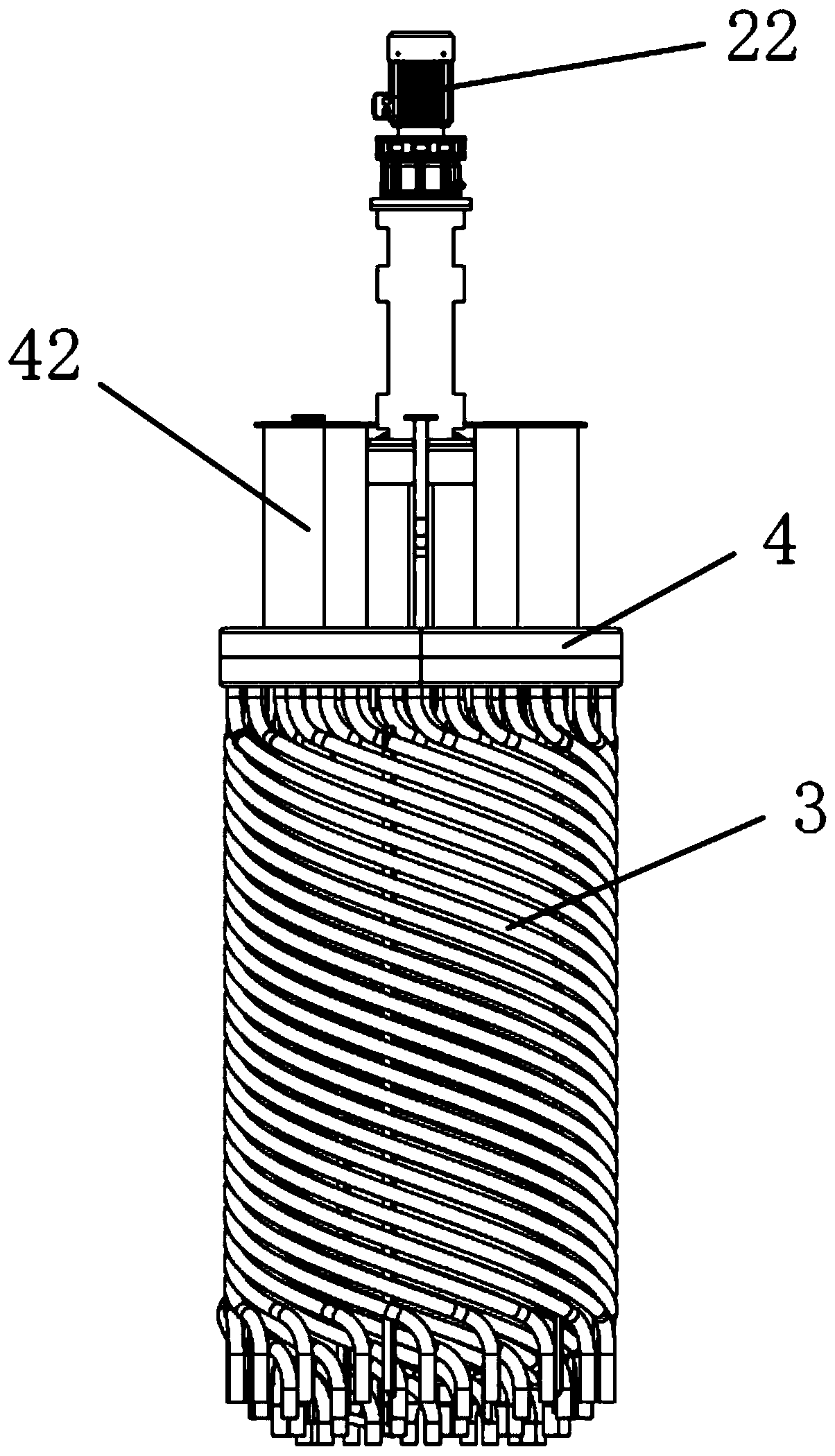

[0047]In the present invention, the heat exchange tube group includes multiple layers of heat exchange units radially distributed along the rotation axis of the stirring shaft; each heat exchange unit includes a plurality of heat exchange straight tubes distributed along the circumference of the rotation axis of the stirring shaft; The inlet of each is connected to the air inlet header, and the outlet of each heat exchange straight pipe is connected to the air collecting chamber.

[0048] Other technical characteristics are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com