Magnetic powder flaw detection equipment for the Internet of Things

A technology of magnetic particle flaw detection and the Internet of Things, which is applied in the direction of material magnetic variables, complex mathematical operations, and adjustment of electrical variables, etc., can solve problems such as low accuracy of magnetizing current of flaw detection equipment, health damage of staff, and influence on other equipment. The effect of causing harm to the human body, improving safety, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

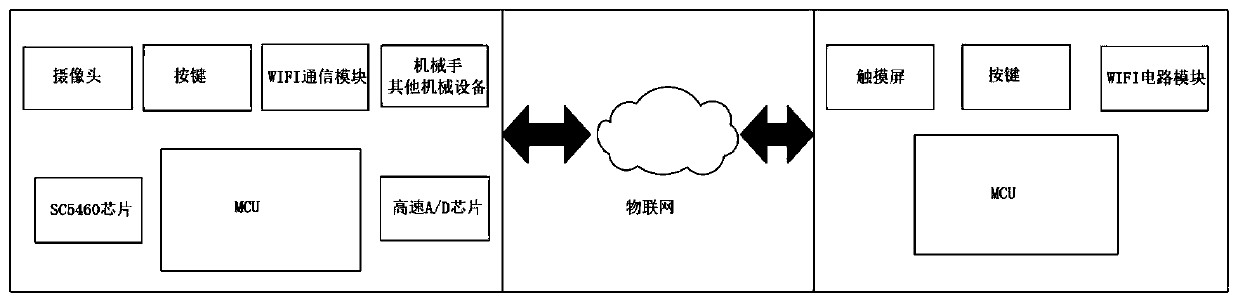

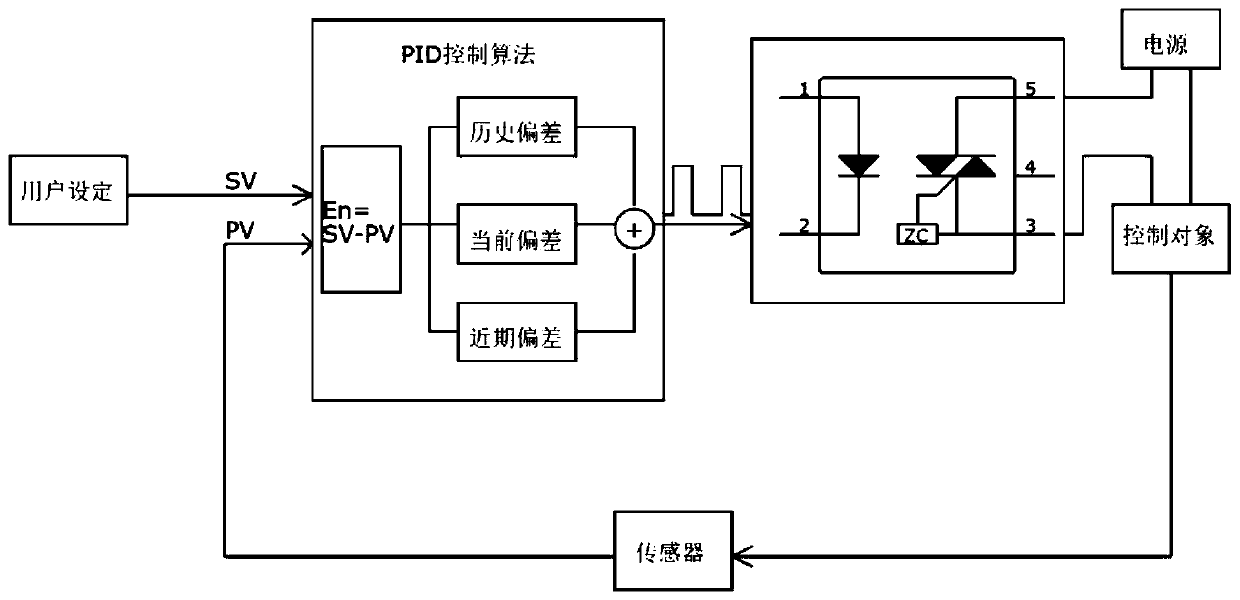

[0042] Embodiment: An Internet of Things magnetic particle flaw detection device, including a flaw detection main part and a remote control part.

[0043] 1. The main part of flaw detection

[0044] Such as figure 1 As shown, the main part of the flaw detection includes a magnetization current setting circuit, a magnetization control circuit, a two-way zero-crossing detection circuit, a remote communication module at the main body end, a camera, a mechanical arm, and a magnetic particle arrangement device.

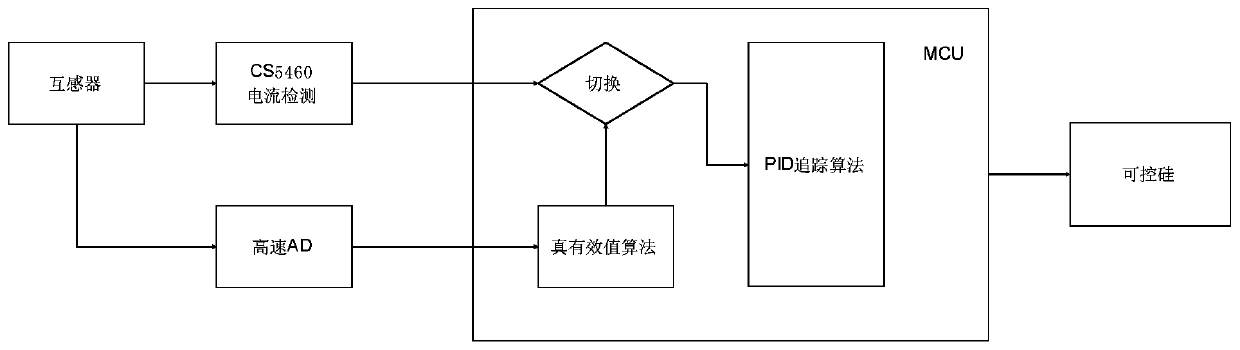

[0045] The magnetizing current setting circuit includes a first MCU, a transformer and a current detection chip connected in communication.

[0046] The transformer measures the magnetization current of the device under test. The current detection chip includes a large current detection chip and a small current detection chip. In this embodiment, the large current detection chip adopts CS5460, and the small current detection chip adopts ADC12DJ5200RF high-speed A / D chip, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com