Method for predicting residual life of wind turbine gearbox bearing

A gearbox and bearing technology, which is applied in the field of predicting the remaining life of wind turbine gearbox bearings, can solve the problem of not considering factors such as sudden failure, and achieve good prediction effect and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

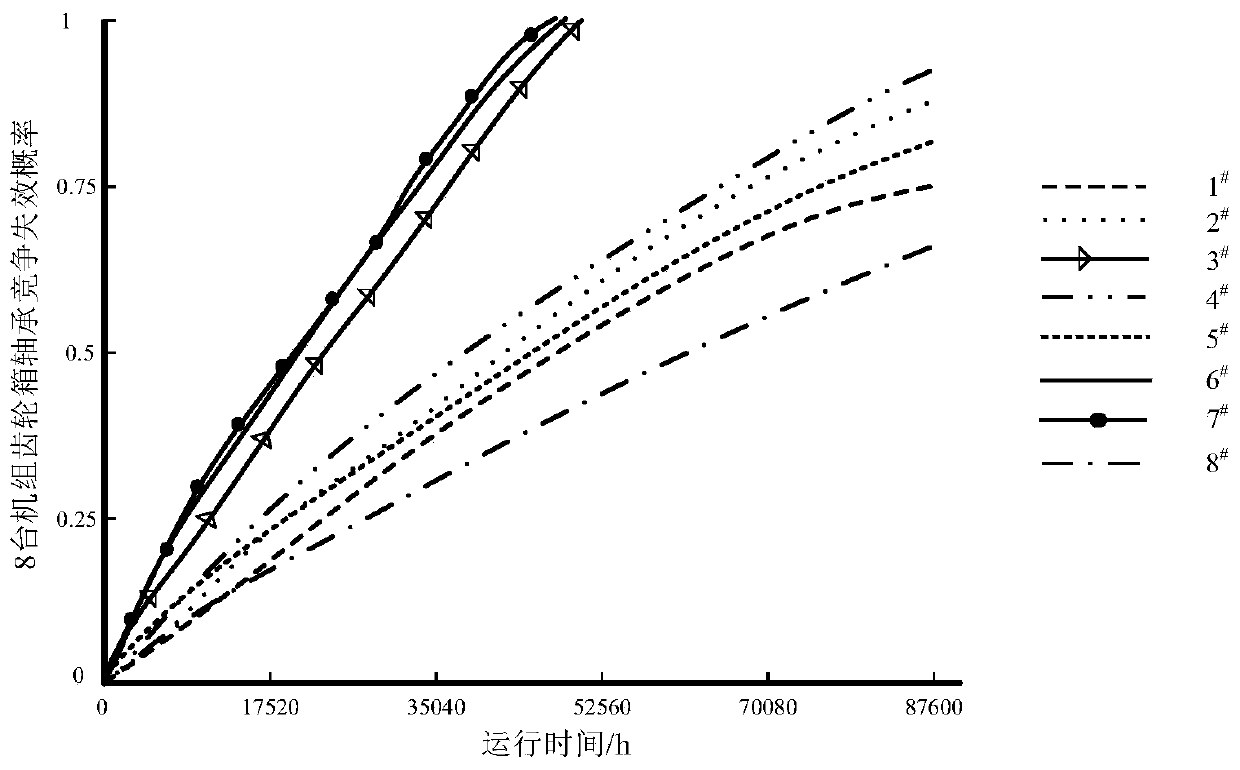

[0068] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

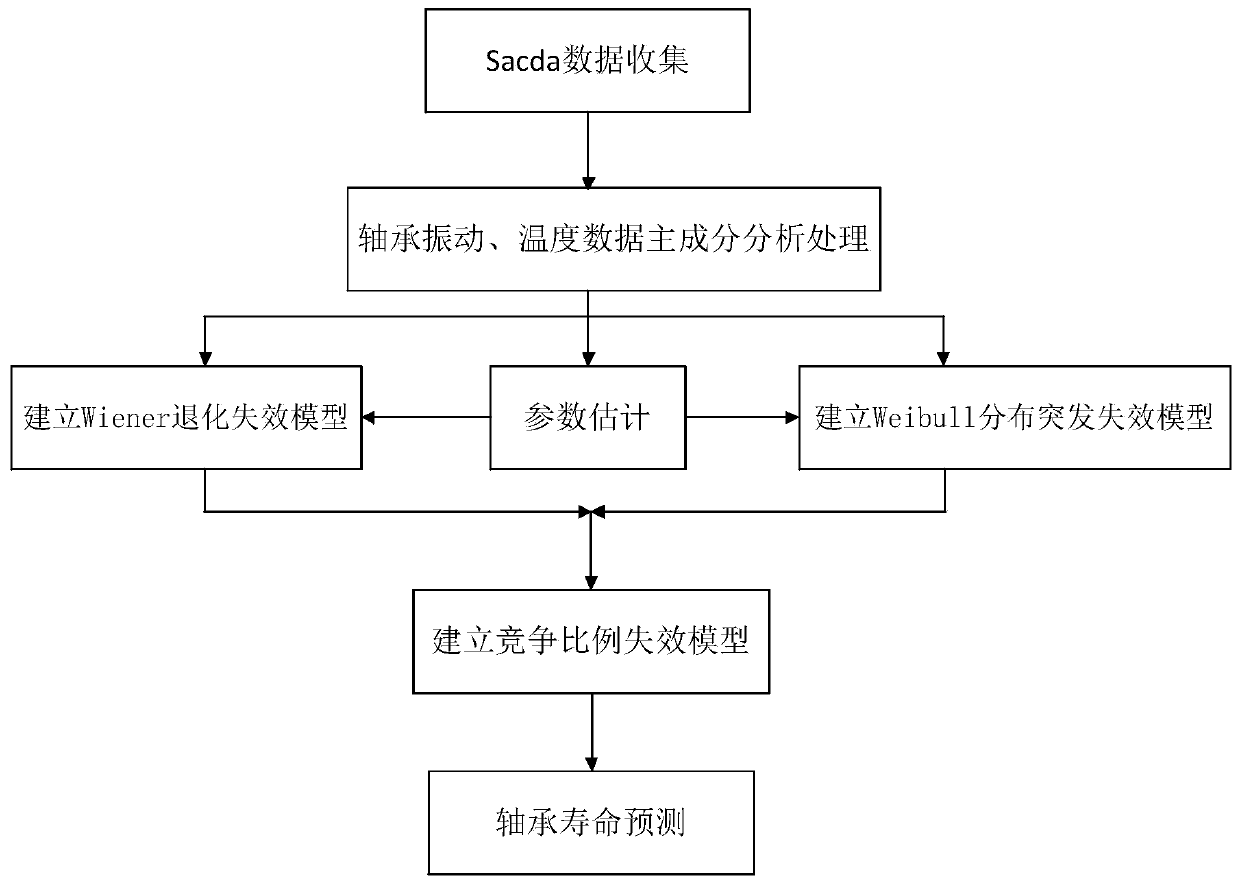

[0069] A method for predicting the remaining life of a wind turbine gearbox bearing proposed by the present invention, the specific flow chart of the embodiment is as attached figure 1 shown, including the following steps:

[0070] S1. Selection of characteristic parameters of wind turbine gearbox bearings based on data

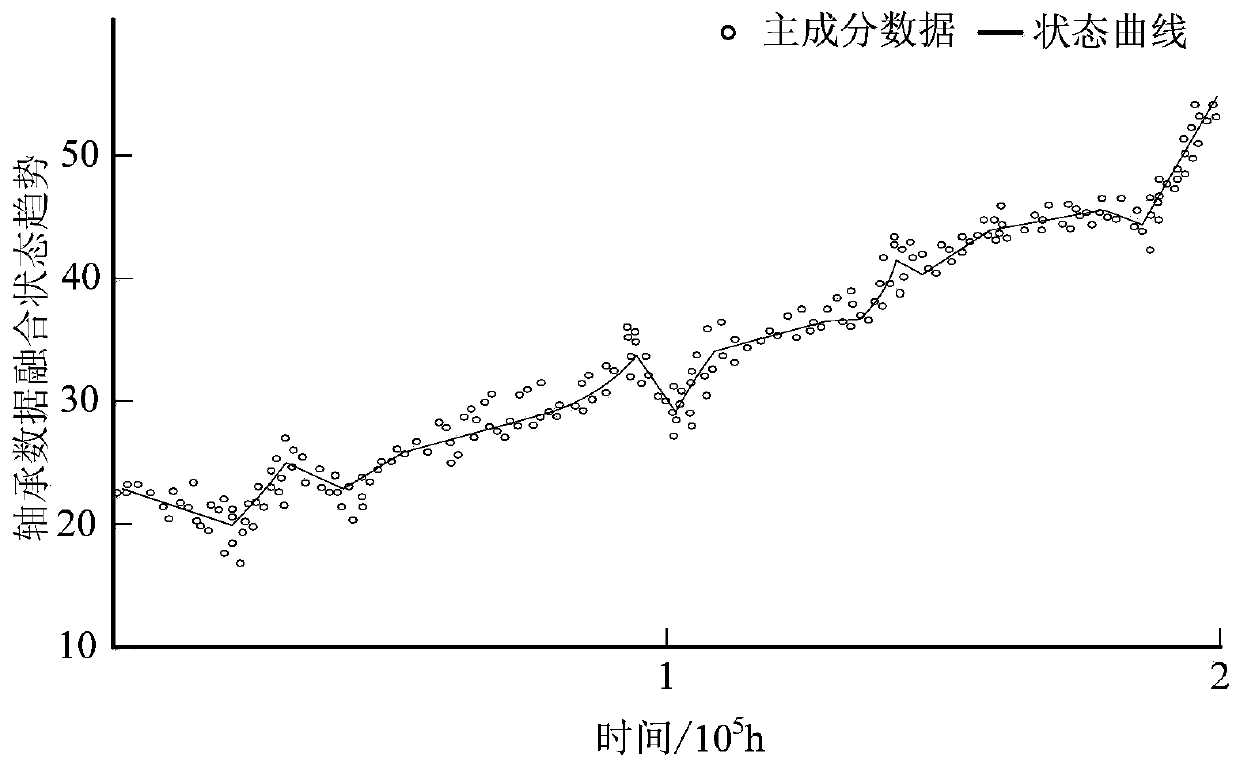

[0071] The SCADA system equipped in the wind farm can monitor the bearings of the gear box in real time, and the monitoring parameters of the bearings can be regarded as internal covariates that cause the performance degradation of the bearings. According to the wind field monitoring data, after the wind turbine gearbox bearing fails, it is mainly reflected in a sharp increase in temperature and an increase in vibration amplitude, and there is no major change in wind speed and lubricating oil parameters. Therefore, the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com