A display substrate and its preparation method

A technology for displaying substrates and substrates, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as short circuit between cathode and anode of electrode materials, and achieve the effect of improving electrode binding quality, improving quality, and ensuring firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

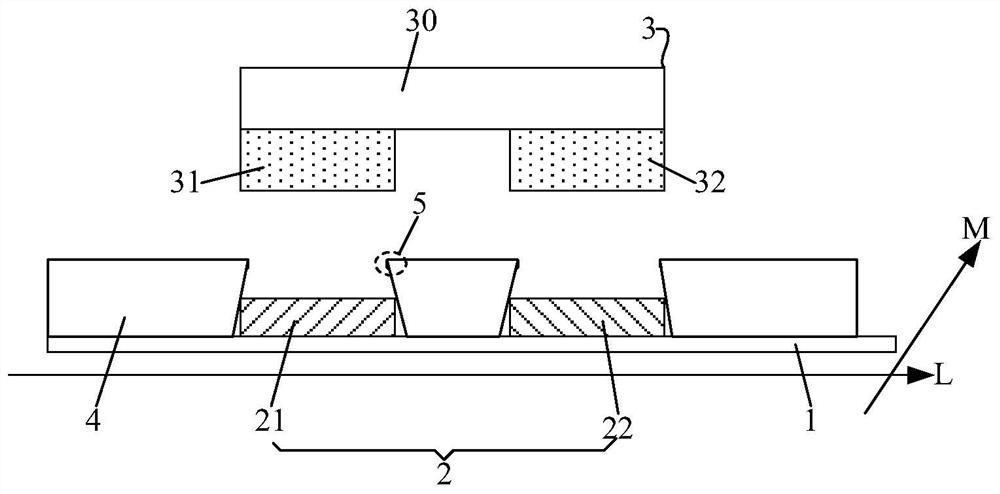

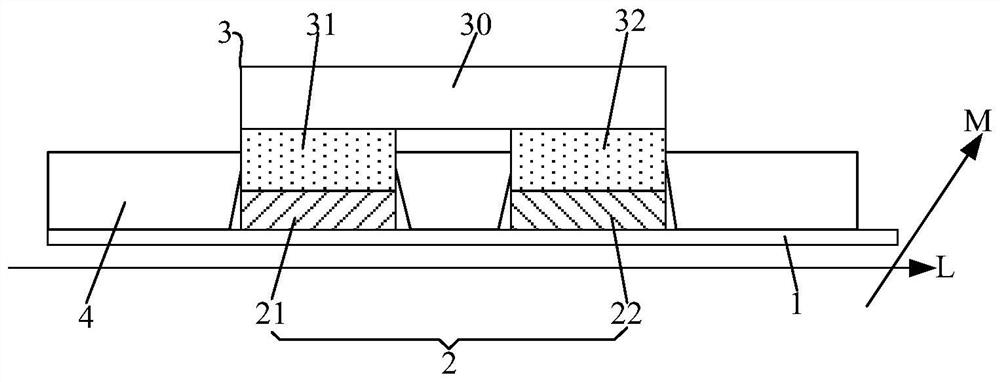

[0054] In order for those skilled in the art to better understand the technical solutions of the present invention, a display substrate and a preparation method thereof of the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

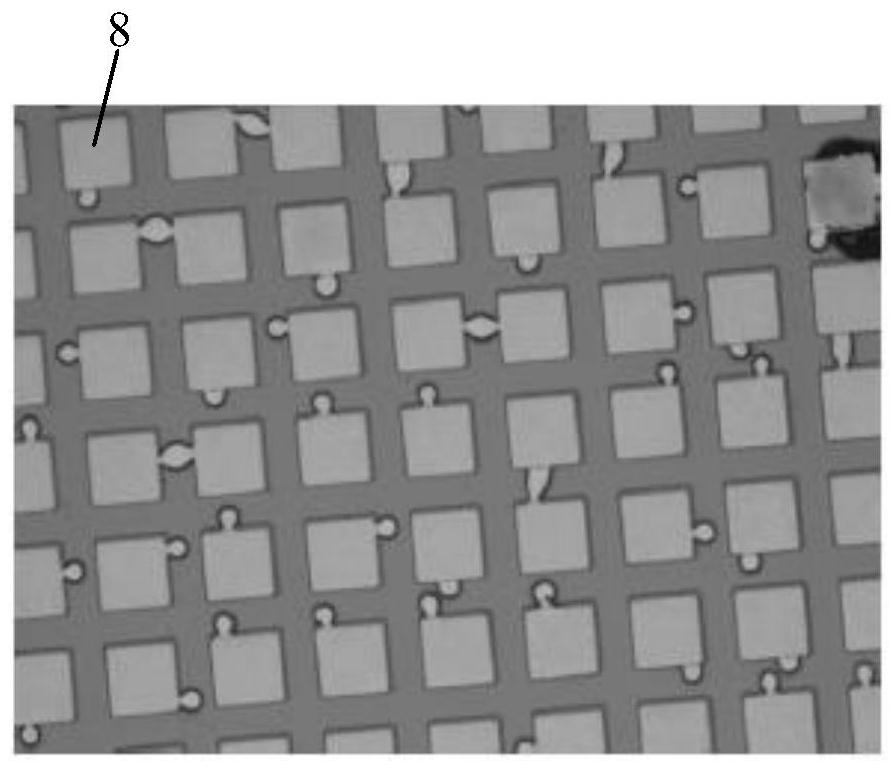

[0055] Currently, a eutectic bonding process is used to bond multiple micron-scale micro-LED chips to a backplane with transistor driver circuits. The traditional LED chip with horizontal electrodes has a large chip size and a large distance between the cathode and the anode. Using eutectic bonding and bonding will not cause the problem of short circuit caused by the liquefaction and flow of the electrode material, but the micro LED chip has a large chip size. Reduced to the micron level, and the distance between chips is close, in the process of using eutectic bonding, it is easy to cause the problem of short circuit between cathode and anode due to liquefaction flow of elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com