PCBA assembly assembling method, assembling jig and PCBA assembly

An assembly method and jig technology, applied in the direction of electrical components, manufacturing tools, electrical components, etc., can solve the problem of reducing the safety and reliability of PCBA components, difficult to ensure the consistency of IPM module installation, and affecting the pin connection of IPM modules. and other problems, to achieve the effect of improving assembly efficiency and convenience, improving plug convenience and reliability, and reducing stress risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

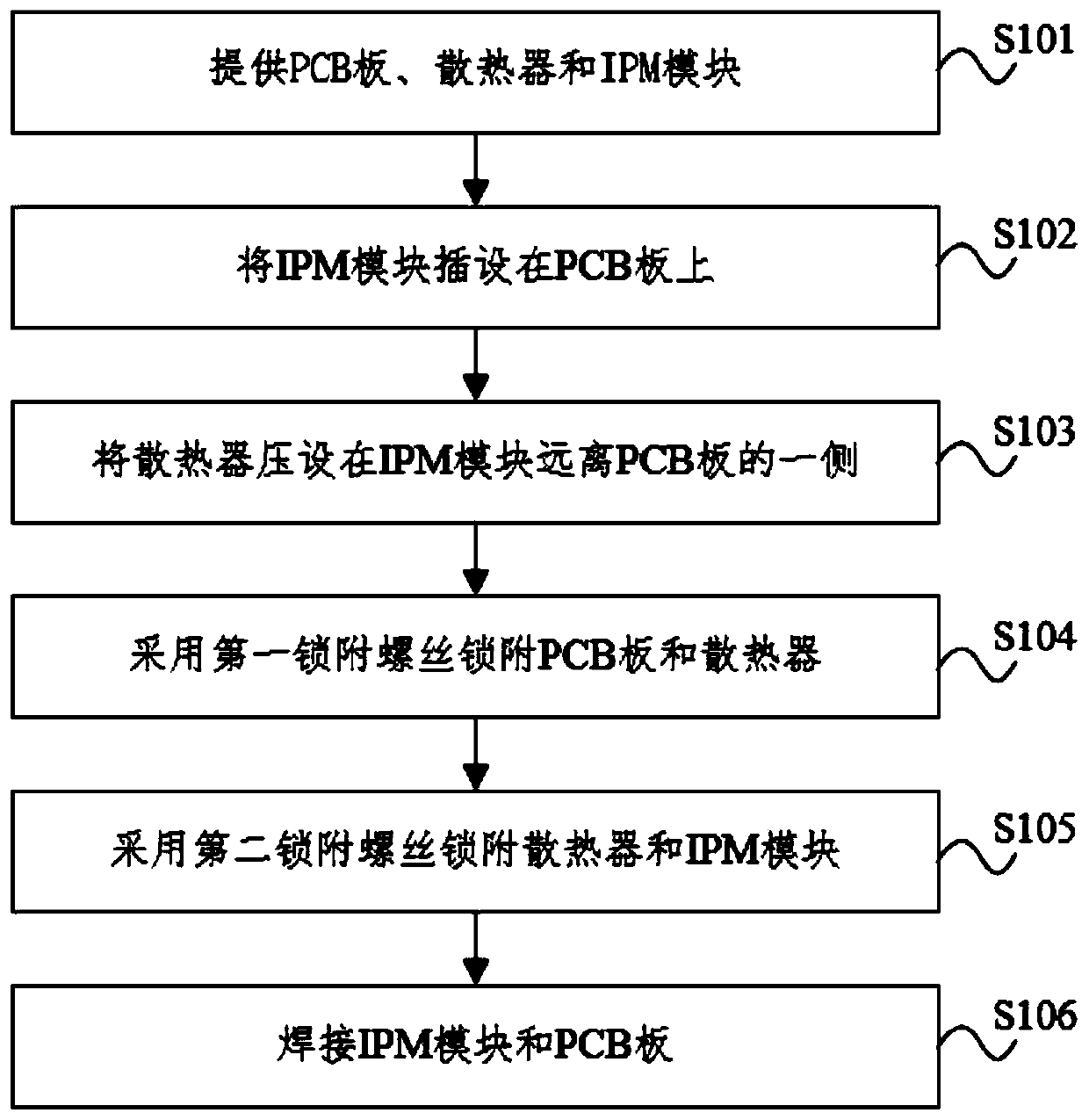

[0051] figure 1 The flowchart of the assembly method of the PCBA assembly provided for the embodiment of the present invention, such as figure 1 As shown, the embodiment of the present invention provides a method for assembling a PCBA assembly, which is used to assemble the IPM module and the heat sink in the PCBA assembly on the PCB board, so as to realize the modular assembly of the PCBA assembly.

[0052] Such as figure 1 As shown, the assembly method of the PCBA assembly provided by this embodiment includes the following steps:

[0053] Step S101, preparing PCB board, IPM module and radiator;

[0054] Step S102, inserting the IPM module on the PCB;

[0055] Step S103, pressing the radiator on the side of the IPM module away from the PCB board;

[0056] Step S104, using the first locking screw to lock the PCB board and the radiator;

[0057] Step S105, using the second locking screw to lock the radiator and the IPM module;

[0058] Step S106, welding the IPM module an...

Embodiment 2

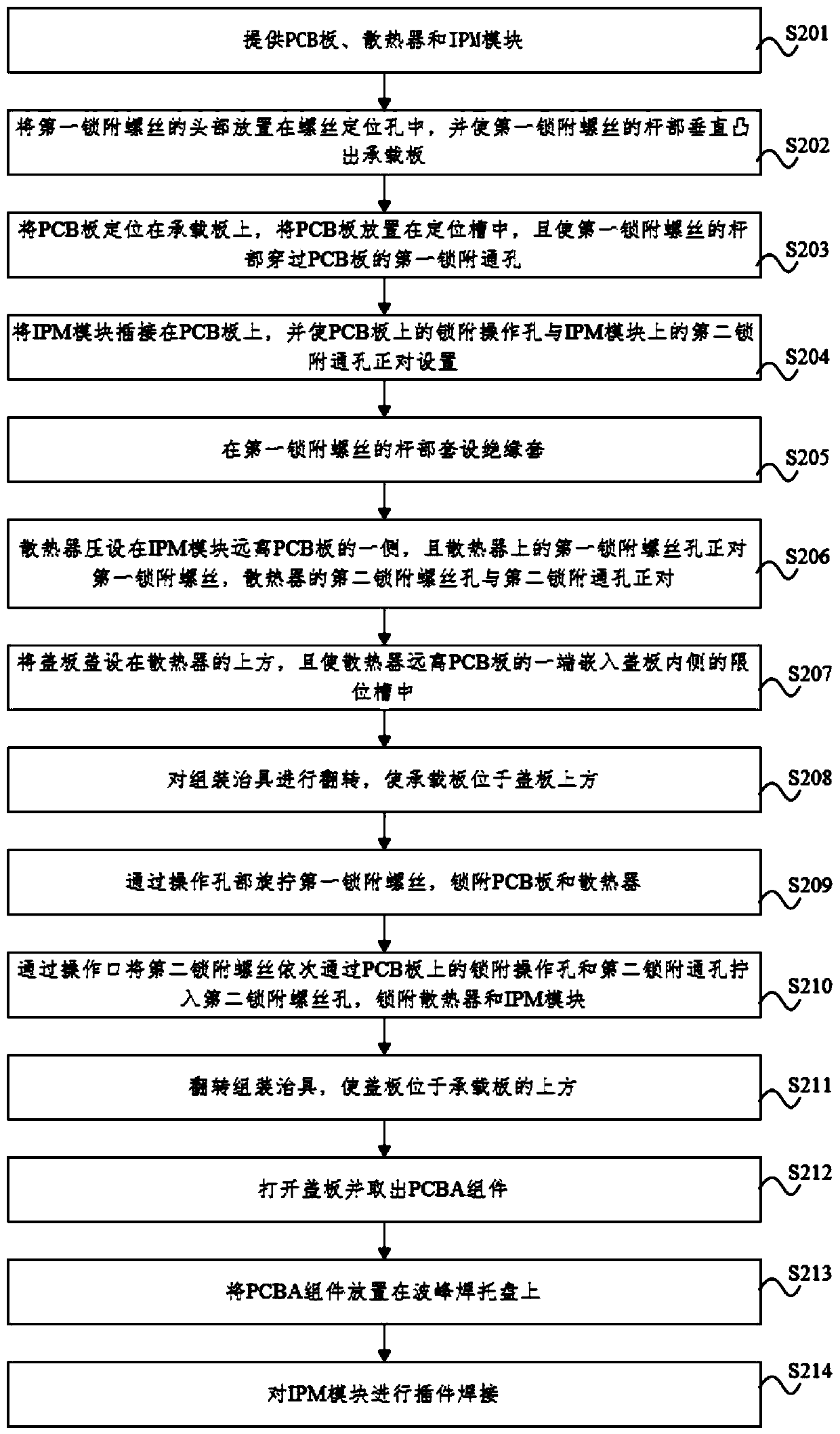

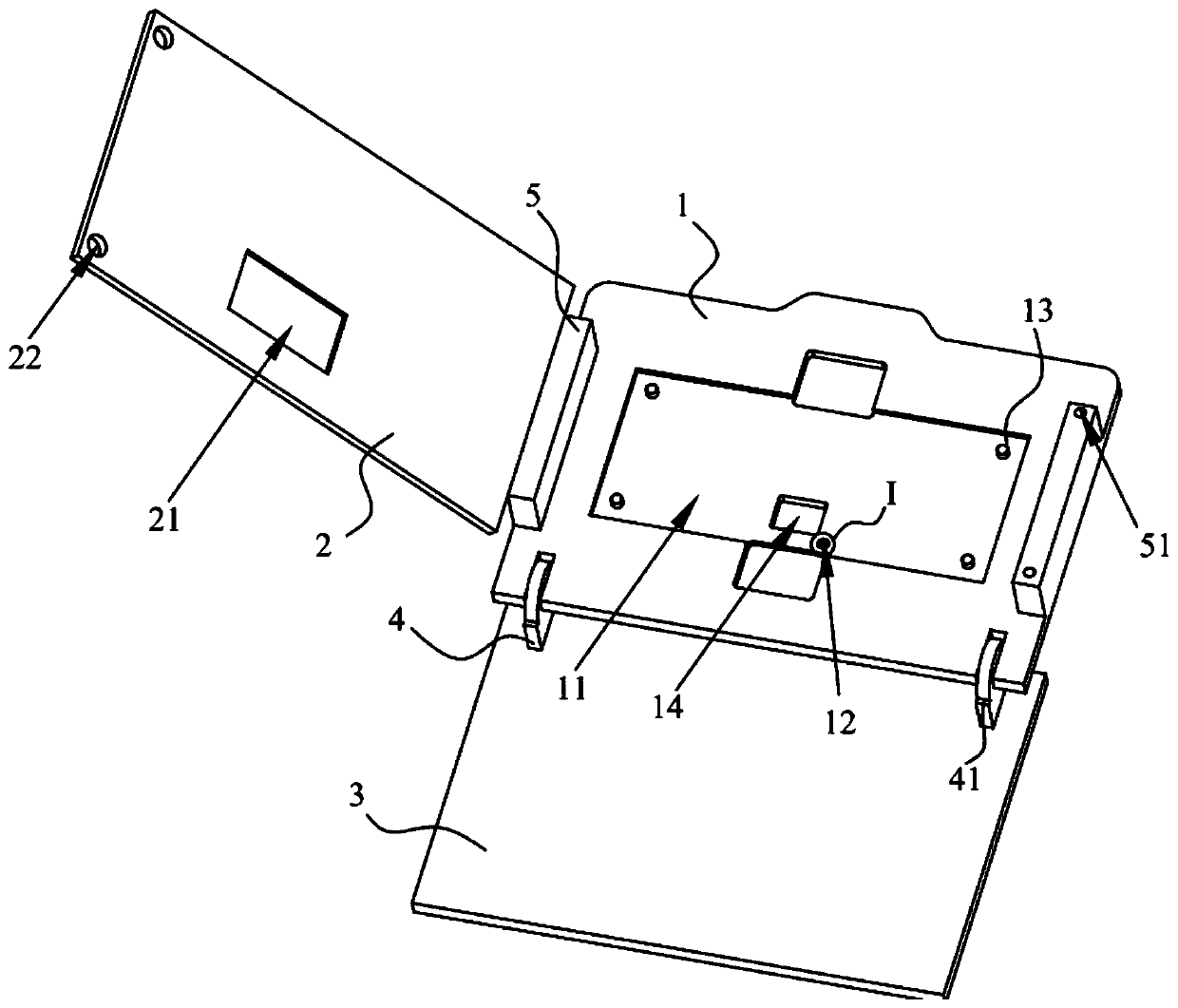

[0061] figure 2 It is a flow chart of the PCBA component assembly method provided by Embodiment 2 of the present invention, image 3 Schematic diagram of the structure of the assembly jig provided by the embodiment of the present invention, Figure 4 for image 3 Partial enlarged view of center I. Such as Figure 2-4 As shown, this embodiment provides a method for assembling PCBA components, which is a further refinement of the method for assembling PCBA components in Embodiment 1, and uses assembly jigs to assemble PCBA components.

[0062] Such as image 3 As shown, the assembly fixture includes a carrier plate 1 for carrying the PCB board. The carrier plate 1 is provided with a positioning groove 11 for positioning the PCB board. The bottom of the positioning groove 11 is provided with an operation port 14 for locking operation. The carrier plate 1 A screw positioning hole 12 is opened on the outside of the positioning groove 11.

[0063] Such as figure 2 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com