Under-floor heating pipe cleaning sand recovery device and under-floor heating pipe cleaning device comprising same

A technology of recycling device and floor heating pipe, applied in the direction of cleaning heat transfer device, flushing, separation method, etc., can solve the problems of complicated operation, large cost investment, damage to the narrow bend of the pipeline, etc., so as to increase the filtering area and improve the filtering effect. , the effect of convenient system circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

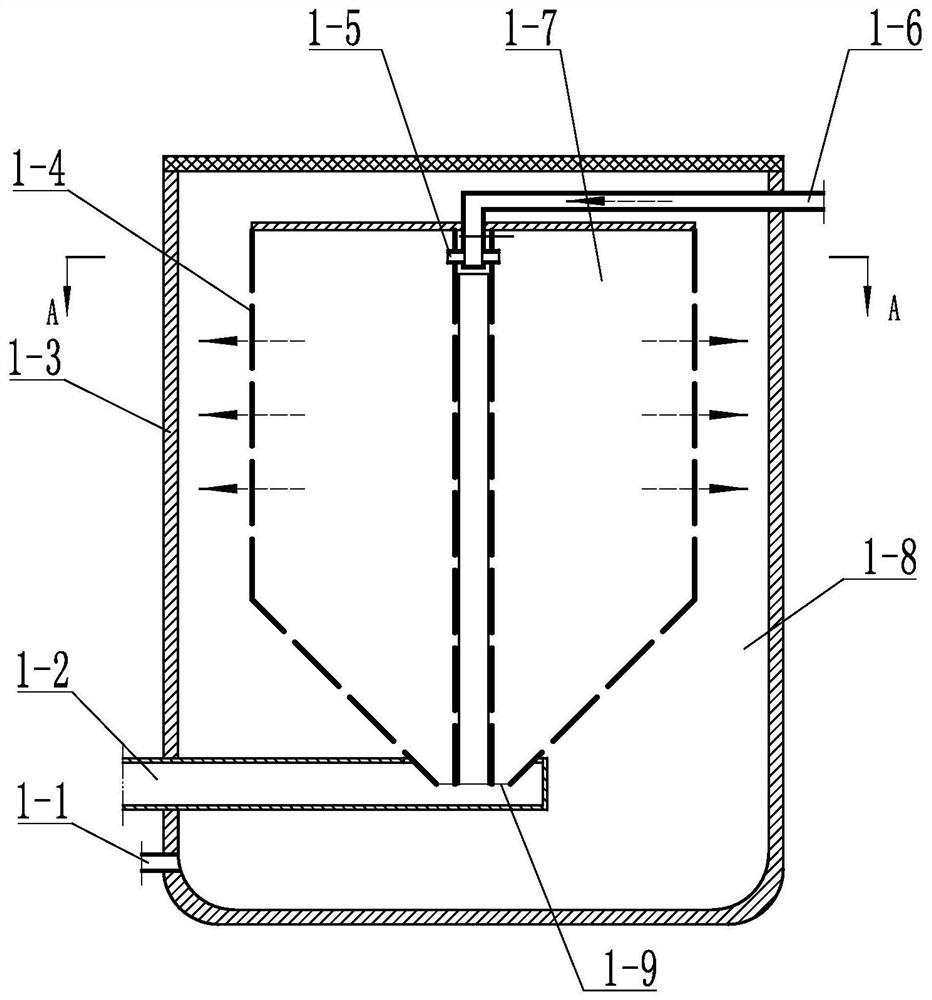

[0076] Embodiment 1: refer to Figure 1~2 , is a structural schematic diagram of Embodiment 1 of the present invention. This embodiment discloses a floor heating pipe cleaning sand recovery device, which includes a barrel body 1-3, and the barrel body 1-3 may be a cup-shaped body with an opening on the top , can also be a sealed cavity, the space surrounded by the barrel body 1-3 is provided with a filter screen 1-4, and the filter screen 1-4 can be surrounded by a water inlet 1-5 and The cavity of the sand discharge port 1-9, that is, the cavity surrounded by the filter screen is the filter cavity 1-7, and the interlayer sleeve 1-8 is between the outside of the filter screen cavity and the barrel body 1-3, and the filter screen 1 -4 can be a sealed filter cavity 1-7, or a cup-shaped body with an open upper part, the water inlet 1-5 is set on the upper part of the filter cavity 1-7, and the sand discharge port 1-9 is set at the filter cavity bottom of cavities 1-7,

[0077] ...

Embodiment 2

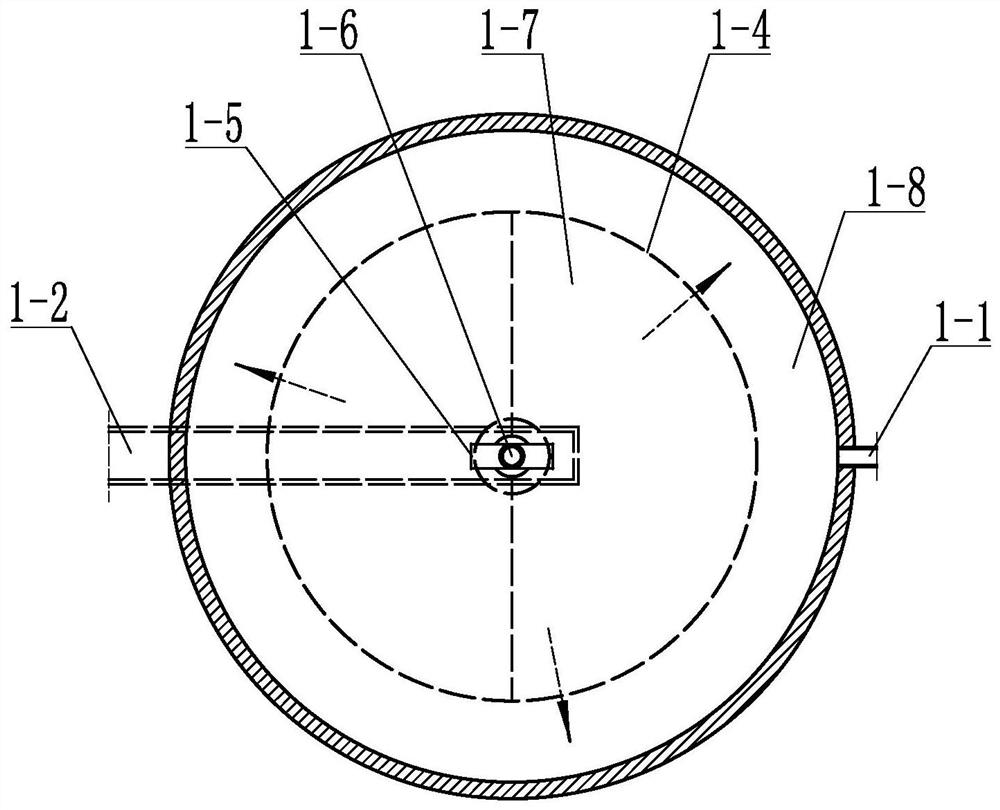

[0086] Embodiment 2: refer to image 3 , is a structural schematic diagram of Embodiment 2 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that there are multiple filter chambers, that is, there are multiple filter chambers 1-7, and each filter chamber 1-7 is Water inlets 1-5 are provided, and water inlet pipes 1-6 are respectively connected with different water inlets 1-5.

[0087] In actual use: Since there are multiple filter chambers 1-7, the sand-water mixture can enter different filter chambers 1-7 through different water inlets 1-5, and in the same volume bucket, the filter screen is enlarged The filter area of 1-4 improves the filter effect and realizes the system circulation more conveniently.

[0088] Each individual filter cavity 1-7 may be a fan-shaped column, and a plurality of fan-shaped columns form a circular column.

[0089] It can also be a columnar body, and a plurality of columnar bodies form a columnar body. ...

Embodiment 3

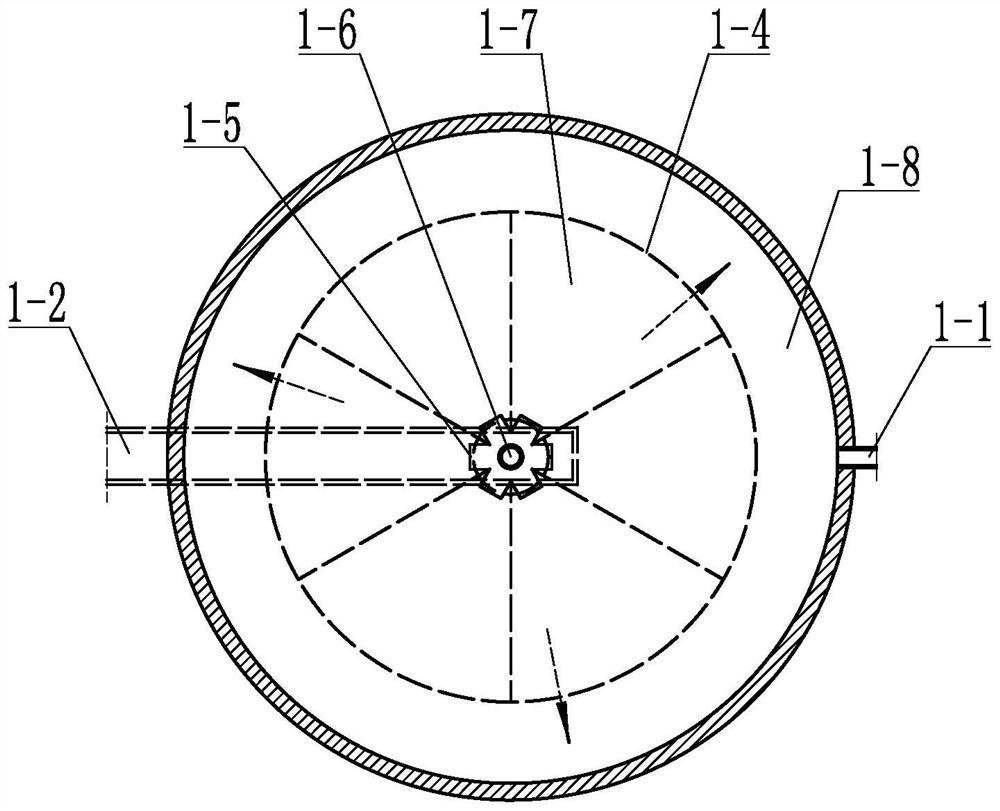

[0090] Embodiment 3: refer to Figure 4~6 , is a structural schematic diagram of Embodiment 3 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that the water outlet direction of the water inlet 1-5 is formed by the surface tangent of the filter screen 1-4 of the filter chamber 1-7. The included angle is α, and α is 5 to 20 degrees.

[0091] In actual use: the sand-water mixture enters the filter chamber 1-7 through the water inlet pipe 1-6 and the water inlet 1-5. Since the water outlet direction of the water inlet 1-5 forms an angle with the surface of the filter screen 1-4, the sand and water mix The liquid can impact on the surface of the filter screen 1-4, and the mixed liquid entering the filter chamber 1-7 can form a swirling flow in the filter chamber 1-7, which improves the filtration efficiency of sand and water, and at the same time cleans the floor heating pipe 6 carried by the sand to be cleaned. The dirt inside can also b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com