Cutting device for casting parts

A technology for cutting devices and casting parts, used in grinding drive devices, grinding/polishing safety devices, manufacturing tools, etc. automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

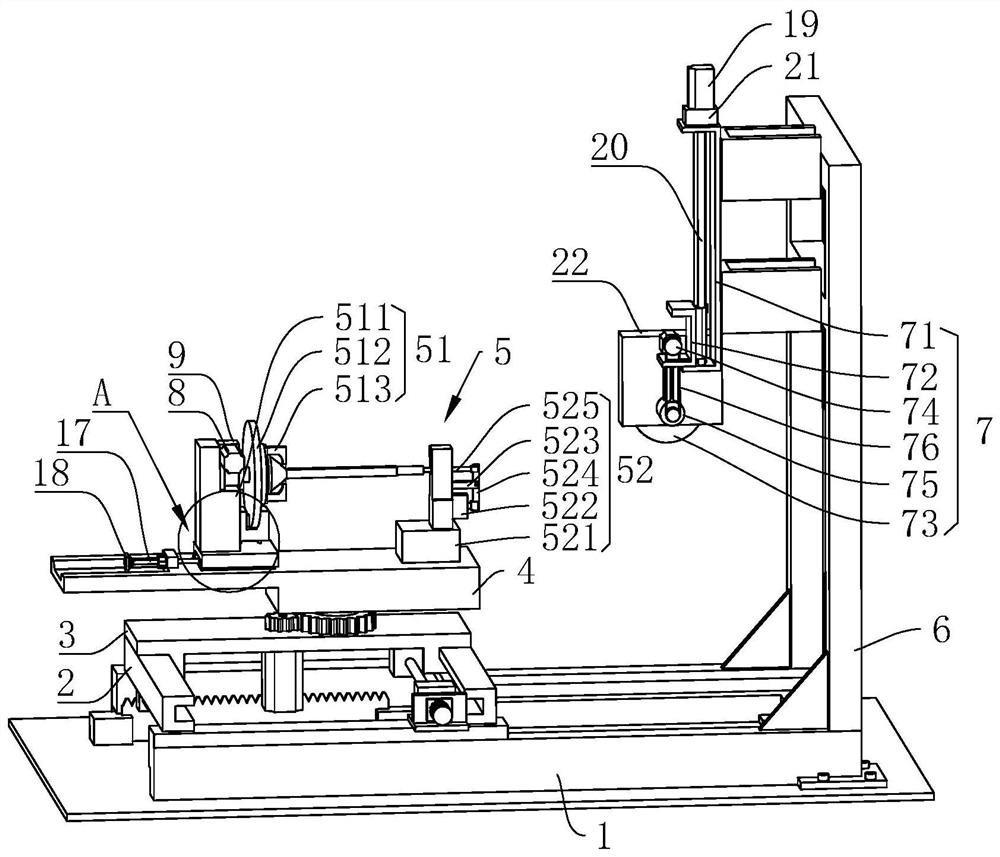

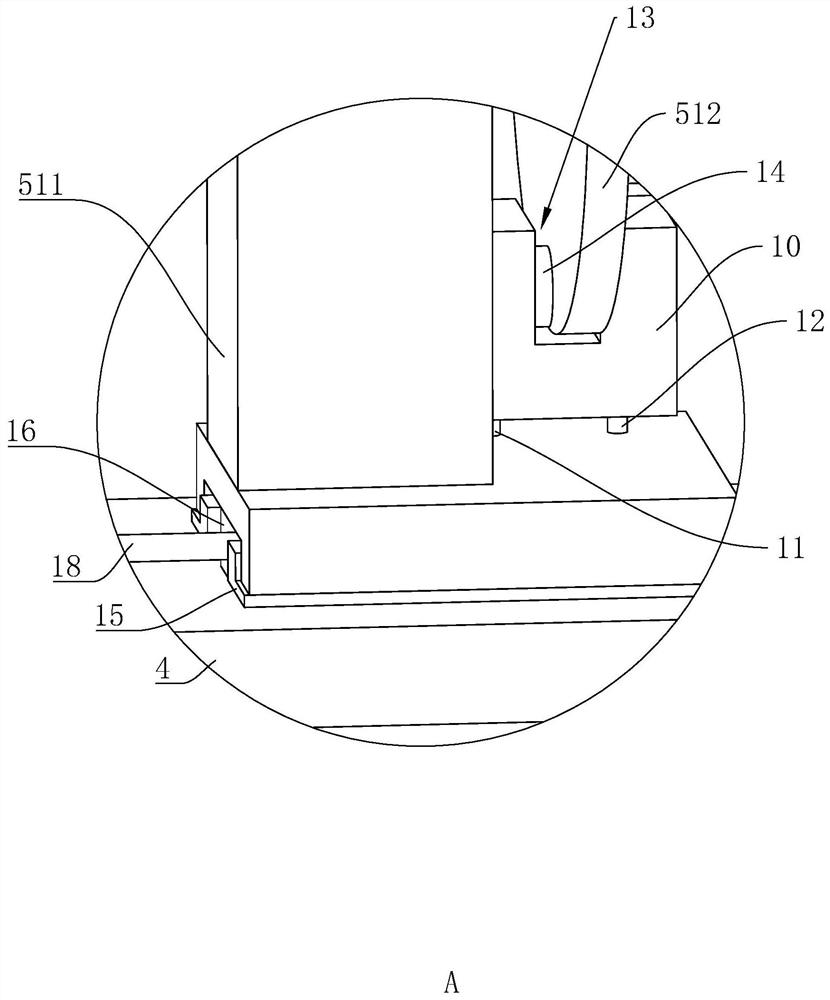

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0033] refer tofigure 1 with figure 2 , is a cutting device for casting parts disclosed in the present invention, comprising a cuboid base 1, a cuboid horizontal sliding block 2 is slidably installed on the top of the base 1, and a cuboid is slidably installed on the end of the horizontal sliding block 2 away from the base 1 Shaped longitudinal sliding block 3, the end of the longitudinal sliding block 3 away from the horizontal sliding block 2 is rotated and installed with a cuboid-shaped rotating platform 4, and the end of the rotating platform 4 away from the longitudinal sliding block 3 is provided with a mounting structure 5 for installing castings, and the base 1 A rectangular parallelepiped vertical plate 6 is welded on the side wall, and the end of the vertical plate 6 close to the transverse sliding block 2 is provided with a cutting structure 7 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com