Preparation method of heterogeneous coal core in soft coal seam

A soft coal seam, heterogeneous technology, applied in the field of soft coal seam heterogeneous coal core preparation, to achieve the effect of simple operation and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

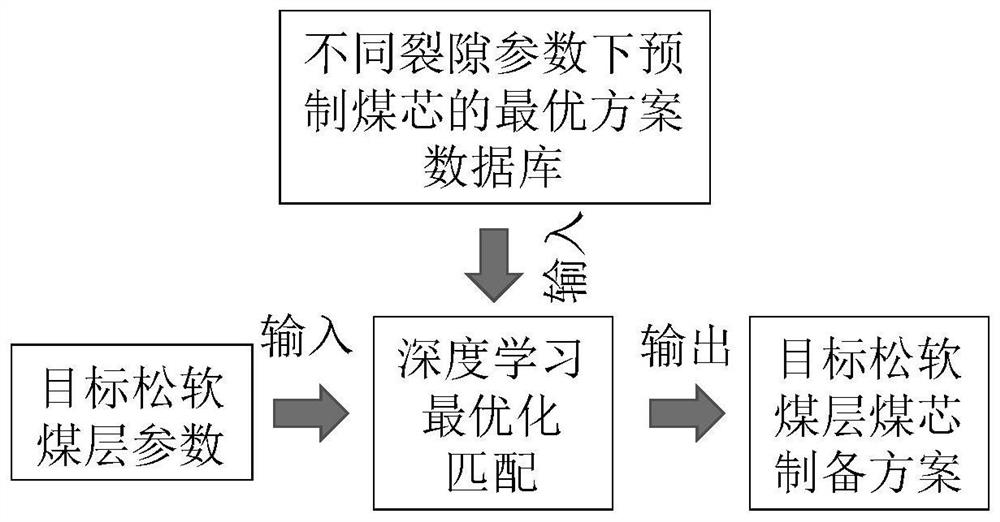

[0036] see figure 1 , the present embodiment provides a method for preparing a soft coal seam heterogeneous coal core, comprising the following steps:

[0037] 1) Measure the in-situ stress, gas pressure and permeability coefficient of the target soft coal seam.

[0038] 2) Using the elastic wave CT data acquisition system to obtain the spatial fracture distribution pattern of the soft coal seam in the prefabricated coal core area, and establish a three-dimensional visual model of the fracture network. Among them, the spatial fracture distribution form includes the fracture occurrence, trace length and spacing parameters.

[0039] 3) The compressive strength, elastic modulus and Poisson's ratio of the soft coal seam in the prefabricated coal core area are obtained by using the in-situ test system of coal and rock mass elastic parameters and physical parameters.

[0040] 4) Construct the optimal scheme database of prefabricated coal core under different fracture parameters. ...

Embodiment 2

[0045] The main steps of this embodiment are the same as in Embodiment 1, wherein the method for constructing the optimal scheme database of prefabricated coal cores under different fracture parameters in step 4 includes the following steps:

[0046] a) Set the fracture geometry parameters such as bedding line density, single bedding dip angle, single bedding width, cleat line density, single cleat dip angle and single cleat width of the pre-prepared coal core to construct the fracture network.

[0047] b) Set the compressive strength, elastic modulus, Poisson's ratio and permeability coefficient to determine the ground stress and gas pressure values.

[0048]c) Determine the original influencing factor set of the uniaxial compressive strength and permeability coefficient of the pre-prepared coal core, apply the gray Taguchi method, design the original influencing factor screening test plan, and prepare the coal core under different original influencing factors by means of 3D p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com