Composite fiber material for multifunctional decorative material and preparation method thereof

A decorative material and composite fiber technology, applied in the field of decorative materials, can solve the problems of poor thermal insulation performance, fireproof and sound insulation performance, restrictions on the application of airgel, low strength and brittleness, etc., to achieve improved thermal insulation effect, high density Effect of small size and improved high temperature resistance

Inactive Publication Date: 2020-09-01

JIANGYIN MEITAI DECORATIVE MATERIALS

View PDF5 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the decorative materials widely used in the market still have certain problems, such as not being environmentally friendly, low strength, high specific gravity, poor thermal insulation performance, fireproof and sound insulation performance, etc.

[0003] As a material with both thermal insulation and light weight effects, airgel still has the problem of low strength and brittleness, and the bonding force with concrete and other substrates is not strong, so it restricts the application of airgel in decorative materials. Applications

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0022] In order to make the above objects, features and advantages of the present invention more comprehensible, the specific implementation of the present invention will be described in detail below in conjunction with specific examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

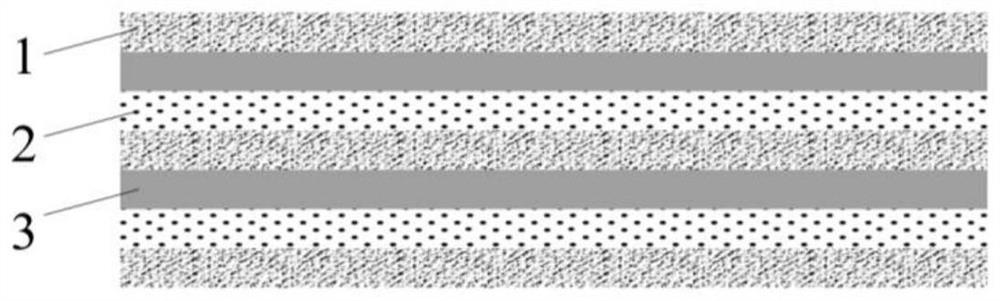

The invention discloses a composite fiber material for a multifunctional decorative material and a preparation method of the composite fiber material. The composite fiber material for the multifunctional decorative material is prepared from, by weight: 18-24 parts of biomass high-strength fibers, 20-26 parts of an adhesive, 39-46 parts of an aerogel composite special fiber material and 10-17 partsof a light reinforcing material. According to the composite fiber material for the multifunctional decorative material, the aerogel is combined with the special fiber with the nano-pore structure, sothat the thermal insulation effect of the obtained composite fiber material is improved, and the composite fiber material has the characteristics of light weight, higher compression resistance and higher tensile strength. Besides, due to the application of the adhesive, the biomass high-strength fibers and the light reinforcing material, the strength of the composite fiber material is further improved, it is guaranteed that the density of the composite fiber material is still small, and the waterproof, fireproof and soundproof effects are achieved accidentally. According to the composite fiber material for the multifunctional decorative material and the preparation method of the composite fiber material, the production cost is low, the used raw materials are safe and easy to obtain, biomass resources are utilized, and environmental protection and economical efficiency of the preparation process are achieved.

Description

technical field [0001] The invention belongs to the field of decorative materials, and in particular relates to a composite fiber material for multifunctional decorative materials and a preparation method thereof. Background technique [0002] With the development of the modern construction industry, people's demand for building decoration materials is increasing, and at the same time, people are paying more and more attention to the functional improvement of decoration materials. However, the decorative materials widely used in the market still have certain problems, such as not being environmentally friendly, low strength, high specific gravity, poor thermal insulation performance, and poor fireproof and sound insulation performance. [0003] As a material with both thermal insulation and light weight effects, airgel still has the problem of low strength and brittleness, and the bonding force with concrete and other substrates is not strong, so it restricts the application...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B32B27/02B32B27/12B32B27/28B32B33/00B32B38/00C04B26/16C04B28/24C09D101/02C09D7/61C09D7/63C09D7/65C09D169/00C09D155/02

CPCB32B5/02B32B5/26B32B27/12B32B33/00B32B38/00B32B38/164B32B2250/20B32B2255/02B32B2255/26B32B2262/02B32B2307/102B32B2307/304B32B2307/3065B32B2307/558C04B26/16C04B28/24C08K2201/011C08L2201/08C09D101/02C09D155/02C09D169/00C09D7/61C09D7/63C09D7/65C09D7/70C04B14/386C04B16/0691C04B14/062C04B18/248C04B28/165C08L75/04C08K7/26C08K5/5425C08L55/02

Inventor 张虎

Owner JIANGYIN MEITAI DECORATIVE MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com