Air inlet cooling system and method of air separation air compressor

A technology of air intake cooling and air compressor, which is applied in energy-saving heating/cooling, mechanical equipment, cold treatment separation, etc., can solve the problems of lack of air compressor consumption reduction, large proportion, etc., and achieve compact design, budget reduction, and load reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

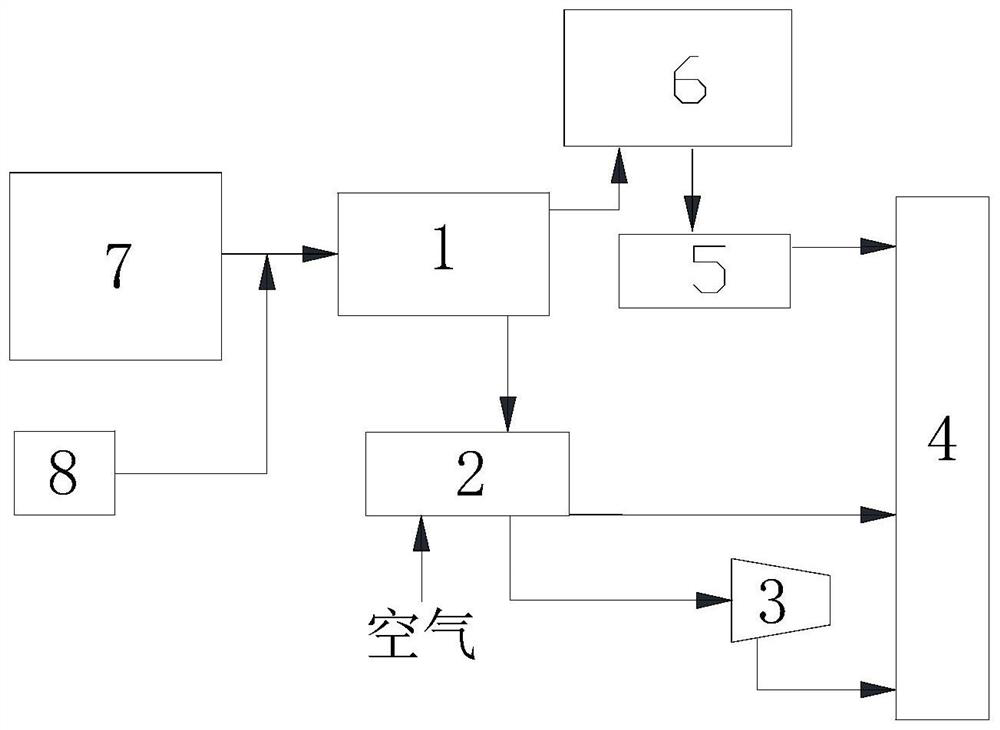

[0033] Such as figure 1 , an air-separation air compressor inlet cooling system, comprising an air-separation precooling system lithium bromide unit 1, a surface cooler 2, an air compressor 3, a circulating water system 4 and a hot water type lithium bromide unit 6.

[0034] The heat source inlet of the lithium bromide unit 1 of the air separation precooling system is connected to the heat energy generated by the air separation system unit 7 and the by-product steam of the steel plant 8, wherein the heat energy generated by the air separation system unit 7 is specifically the cooling heat of the steam turbine, the air compressor The interstage compression heat of the nitrogen compressor, the interstage compression heat of the nitrogen compressor, and the interstage compression heat of the argon compressor.

[0035] The steam condensed water produced by the lithium bromide unit 1 of the air separation precooling system enters the hot water type lithium bromide unit 6 as a heat ...

Embodiment 2

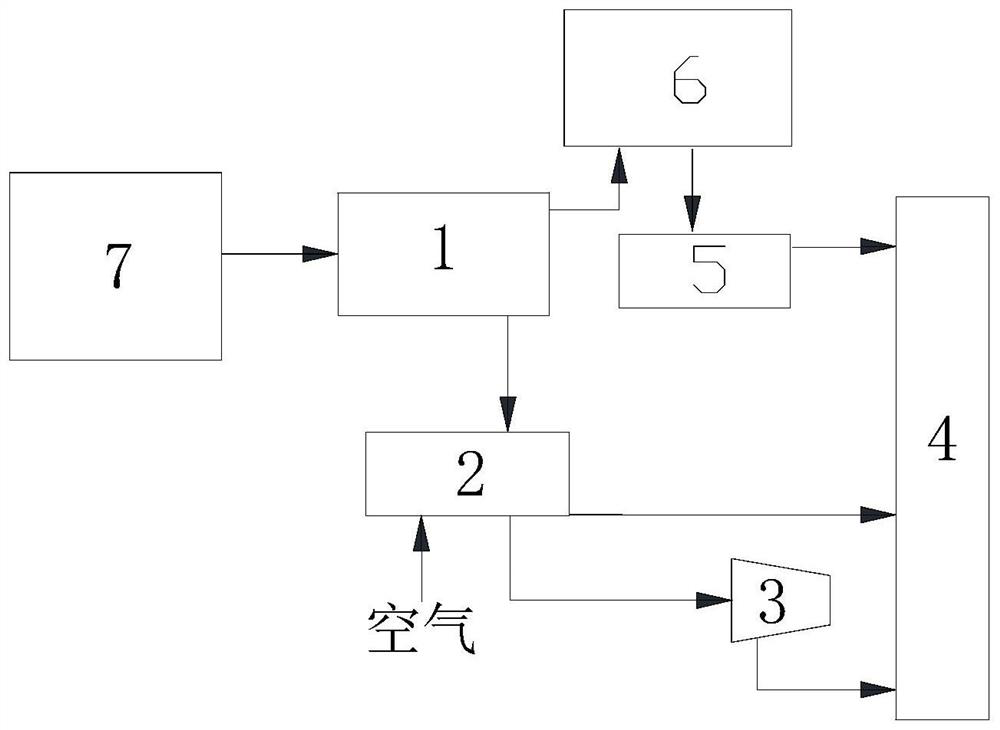

[0038] Such as figure 2 , an air-separation air compressor inlet cooling system, comprising an air-separation precooling system lithium bromide unit 1, a surface cooler 2, an air compressor 3, a circulating water system 4 and a hot water type lithium bromide unit 6.

[0039] The heat source inlet of the lithium bromide unit 1 of the air separation precooling system is connected to the heat energy generated by the air separation system unit 7, wherein the heat energy generated by the air separation system unit 7 is specifically the cooling heat of the steam turbine, the interstage compression heat of the air compressor, and the nitrogen compressor. Interstage compression heat and interstage compression heat of argon compressor.

[0040] The steam condensed water produced by the lithium bromide unit 1 of the air separation precooling system enters the hot water type lithium bromide unit 6 as a heat source, and the steam condensed water produced by the hot water type lithium bro...

Embodiment 3

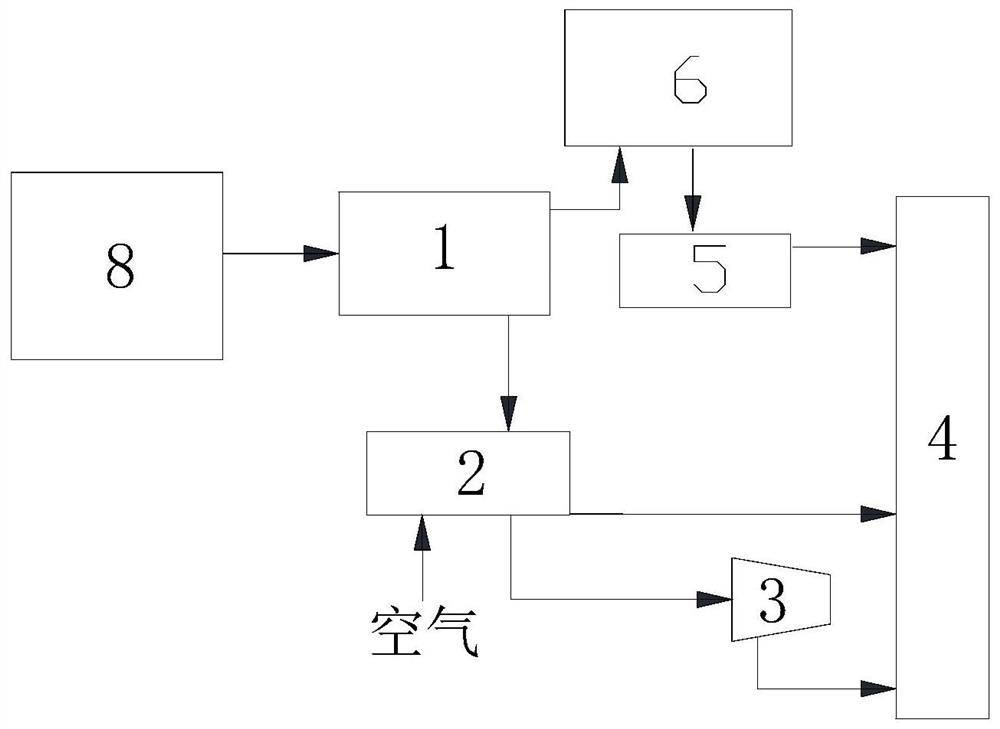

[0043] Such as image 3 , an air-separation air compressor inlet cooling system, comprising an air-separation precooling system lithium bromide unit 1, a surface cooler 2, an air compressor 3, a circulating water system 4 and a hot water type lithium bromide unit 6.

[0044] The heat source inlet of the lithium bromide unit 1 of the air separation precooling system is connected to the by-product steam of the steelmaking plant 8 .

[0045] The steam condensed water produced by the lithium bromide unit 1 of the air separation precooling system enters the hot water type lithium bromide unit 6 as a heat source, and the steam condensed water produced by the hot water type lithium bromide unit 6 enters the condensed water recovery device 5 and then enters the circulating water system 4 .

[0046] The chilled water produced by the lithium bromide unit 1 of the air separation precooling system enters the surface cooler 2 as a cooling medium to cool the air in the surface cooler 2; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com