Liquid hydrogen sampling mechanism on discharge pipe of liquid hydrogen storage tank

A discharge pipe and liquid hydrogen technology, applied in the field of liquid hydrogen storage tanks, can solve the problems of long detection period, influence of liquid hydrogen storage, easy pollution, etc., and achieve the effects of shortened detection period, stable flow, and convenient installation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

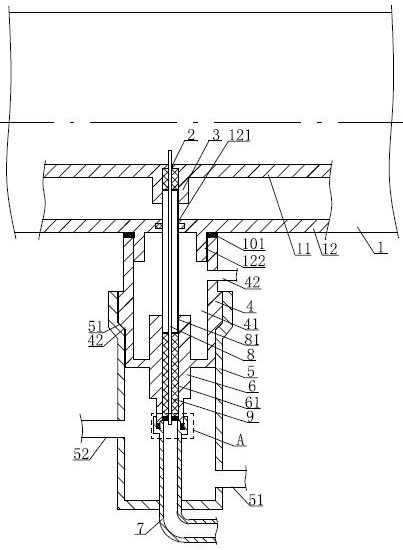

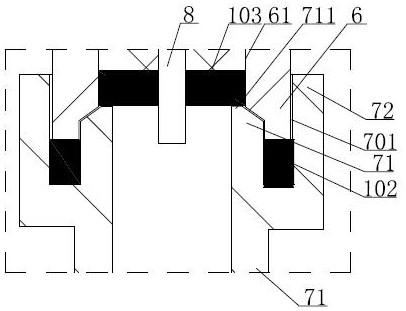

[0015] Such as figure 1 , figure 2 As shown, the liquid hydrogen sampling mechanism on the discharge pipe of the liquid hydrogen storage tank, the discharge pipe 1 includes an inner pipe 11 and an outer pipe 12, and a cavity is formed between the inner pipe 11 and the outer pipe 12. A sampling port 2 is provided on the inner tube 11, and an inner tube connection seat 3 protruding toward the direction of the outer tube 12 is provided on the outer wall of the inner tube 11 at the sampling port 2, and a connecting through hole 121 is provided on the outer tube 12. An insulating cylinder 4 is sealed and fixed on the outer wall of the outer tube 12 , an insulating chamber 41 is formed inside the insulating cylinder 4 , and a vacuum adapter 42 for evacuating the insulating chamber 41 is connected to the insulating cylinder 4 . When vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com