A calibration device and method for testing the internal force of pile foundation by line measurement method

A calibration method and a technology for testing piles, which are applied in the direction of measuring devices, measuring force, and optical devices, etc., can solve the problem of the inconclusiveness of the test accuracy of the internal force of the pile foundation by the line measurement method, and the difficulty of co-deformation of the test components and the pile body. assessment and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

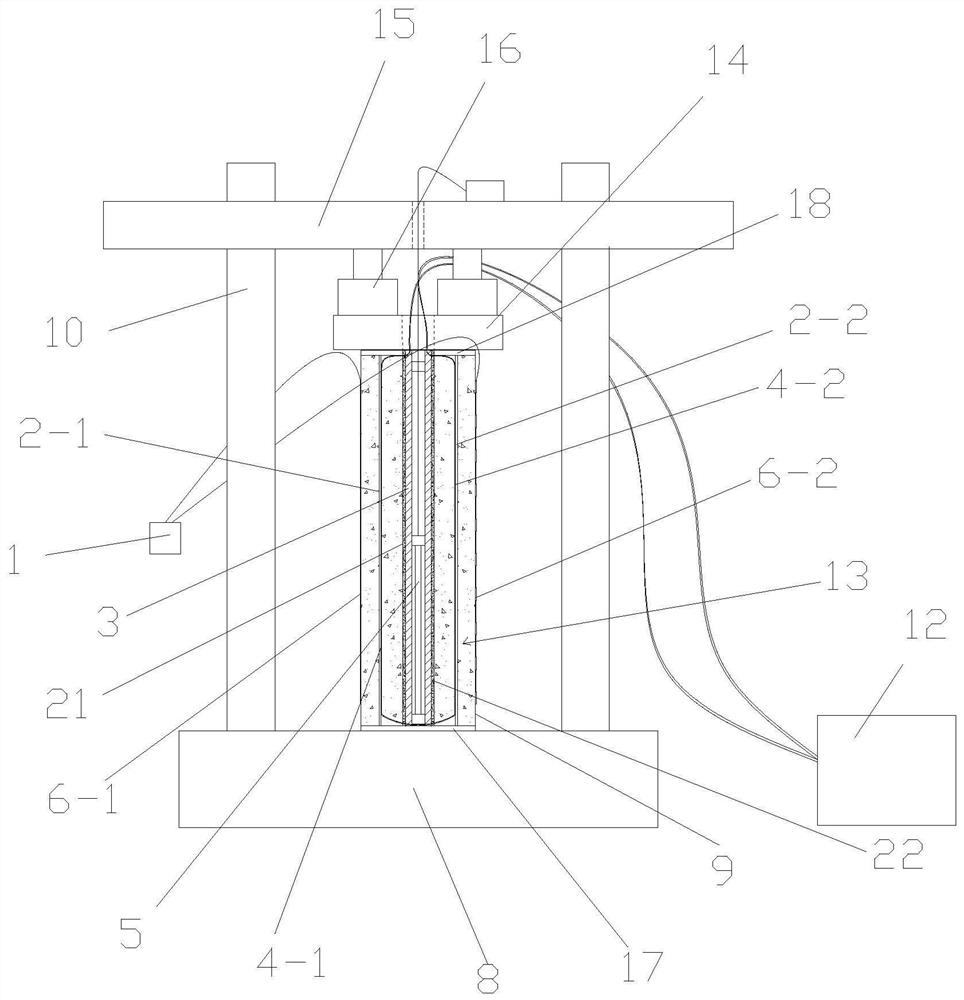

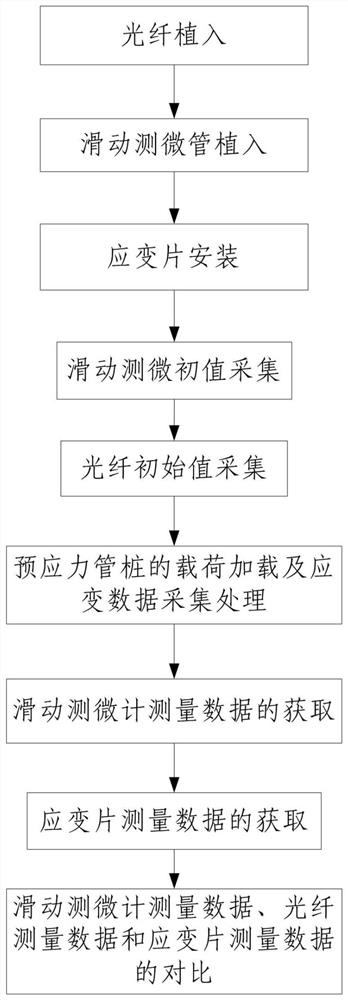

[0097] Such as figure 1 The calibration device for testing the internal force of a pile foundation by the line measurement method includes an optical fiber structure and a sliding micrometer structure arranged in the prestressed pipe pile 9 and a strain gauge structure arranged outside the prestressed pipe pile 9. The optical fiber structure is arranged along the steel cage in the prestressed pipe pile 9, and the optical fiber structure includes the first optical fiber 4-1 and the second optical fiber 4-2 and the bottom connected to the bottom of the first optical fiber 4-1 and the second optical fiber 4-2 The transition optical fiber, the first optical fiber 4-1 and the second optical fiber 4-2 are arranged symmetrically about the center of the reinforcement cage, the first optical fiber 4-1 is arranged along the first main reinforcement 2-1 in the reinforcement cage, and the The second optical fiber 4-2 is laid along the second main reinforcement 2-2 in the reinforcement cag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com