Stayed cable tensioning method for cable-stayed bridge with optimal cable force in construction process

A cable-stayed cable, the original technology of cable-stayed cable, applied in design optimization/simulation, constraint-based CAD, geometric CAD, etc., can solve the problems of wasting manpower, material resources and construction period, poor cable adjustment effect, easy wear of anchor head, etc. , to achieve the effect of reducing disturbance, optimizing cable force and uniform cable force value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

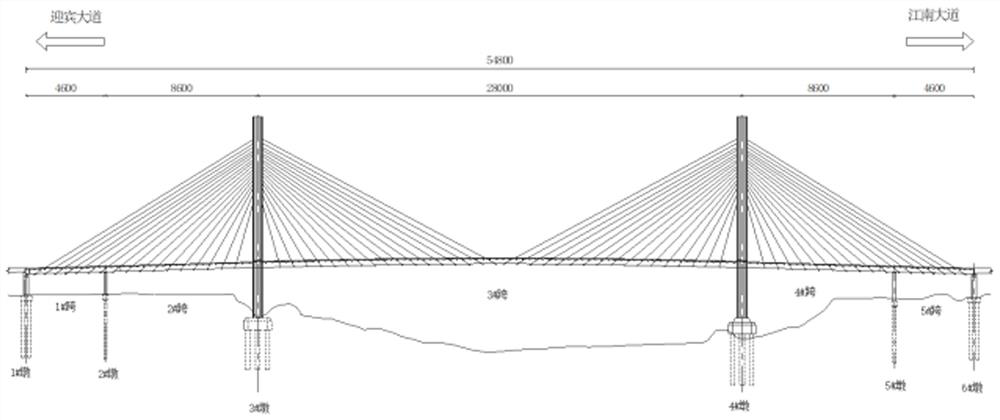

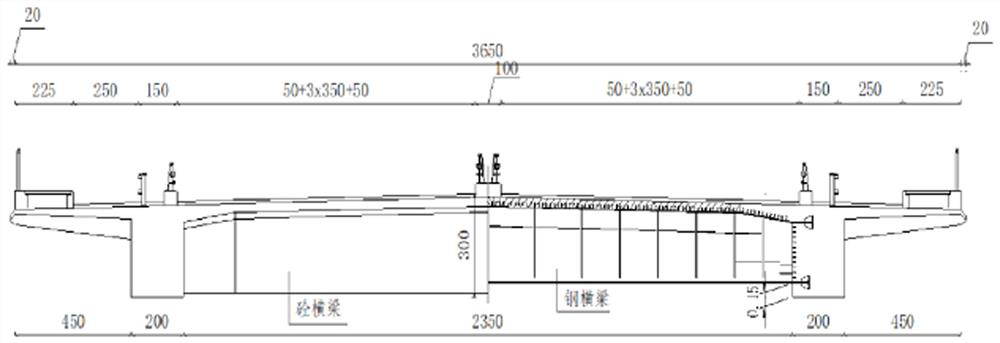

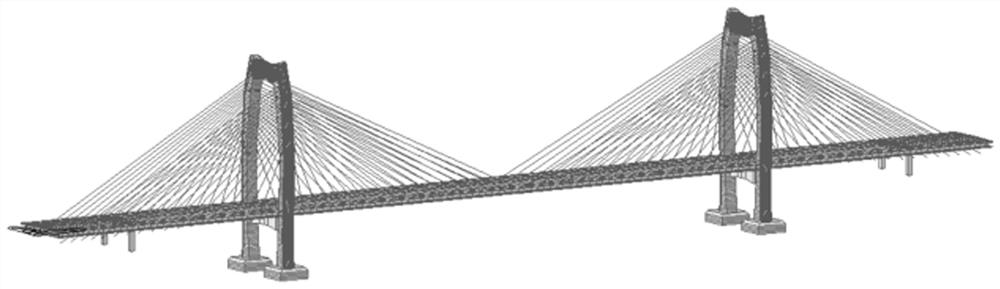

[0040] The total length of a cable-stayed bridge is 548m, and the bridge span is composed of: 46m+88m+280m+88m+46m. A cable-stayed bridge is designed as a prestressed concrete girder structure with twin towers and double cable planes. The main girder adopts a side girder structure. The cable stay cables adopt a galvanized steel strand system assembled on site. The main tower adopts arc-shaped portal frame reinforcement. Concrete structure, see attached figure 1 ;"I"-shaped steel beams are divided into four types: I, II, III, and IV according to the width of the bridge. The thickness of the stiffener is 10mm, the material is Q345qD, and each piece of standard steel beam weighs about 13.3t. figure 2 ; The cable stays of a cable-stayed bridge are arranged in a fan-shaped space with double cable planes, using Φs15.2mm galvanized steel strands with a standard strength of 1860MPa. The overall protection of the HDPE cable casing of the line. The whole bridge has 136 stay cables a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com