Electric paddy field weeding machine

A weeder and paddy field technology, applied in the field of agricultural machinery, can solve the problems of difficult weed removal, waste of herbicides, low effect, etc., and achieve the effects of convenient operation, water environment protection, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better help understand the technical solution of the present application, the specific implementation manners of the present application will be described in detail below in conjunction with the accompanying drawings.

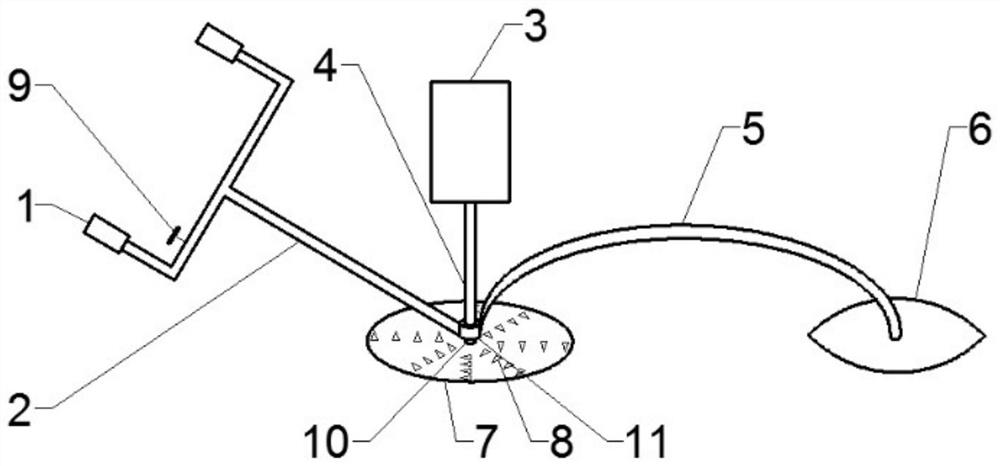

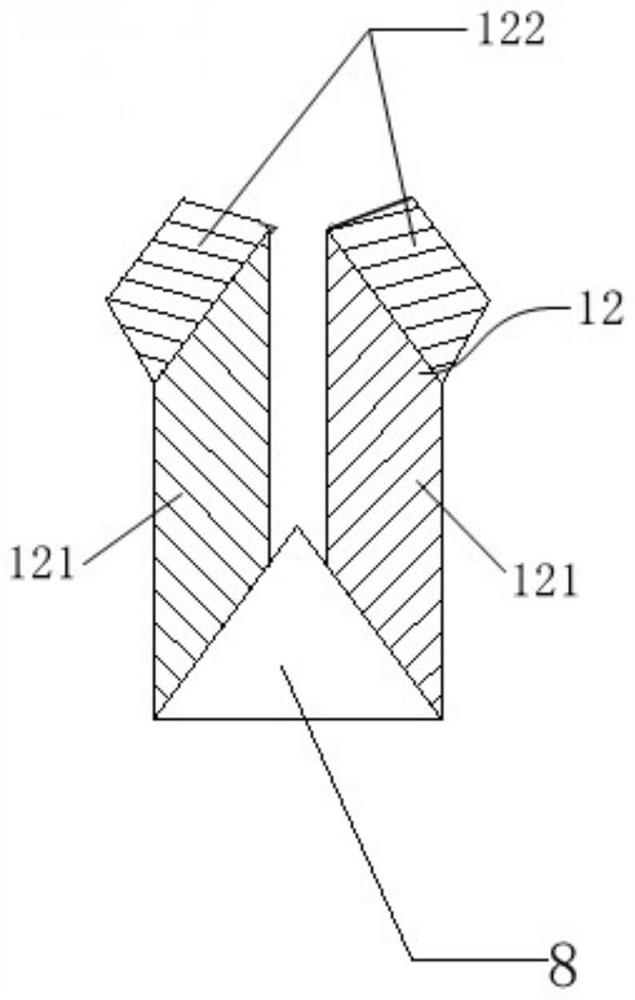

[0017] figure 1 A schematic structural view of the electric paddy field weeder of the present application is shown. Such as figure 1 As shown, the electric rice field weeder mainly includes a handle 1, a push rod 2, a rechargeable motor 3, a rotating disc 7 and a floating plate member 6.

[0018] The handle 1 is generally U-shaped and includes two grips and a grip connecting rod connecting the two grips. One end of the push rod 2 is fixedly connected to the connecting rod of the grip part of the handle 1 , and the other end of the push rod 2 is connected to the rotating shaft 10 of the rotating disk 7 through a bearing 11 . The push rod 2 is preferably a telescoping rod member.

[0019] The rechargeable motor 3 is connected with the rotat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Waist length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Extension length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com