A kind of three-color egg sausage and preparation method thereof

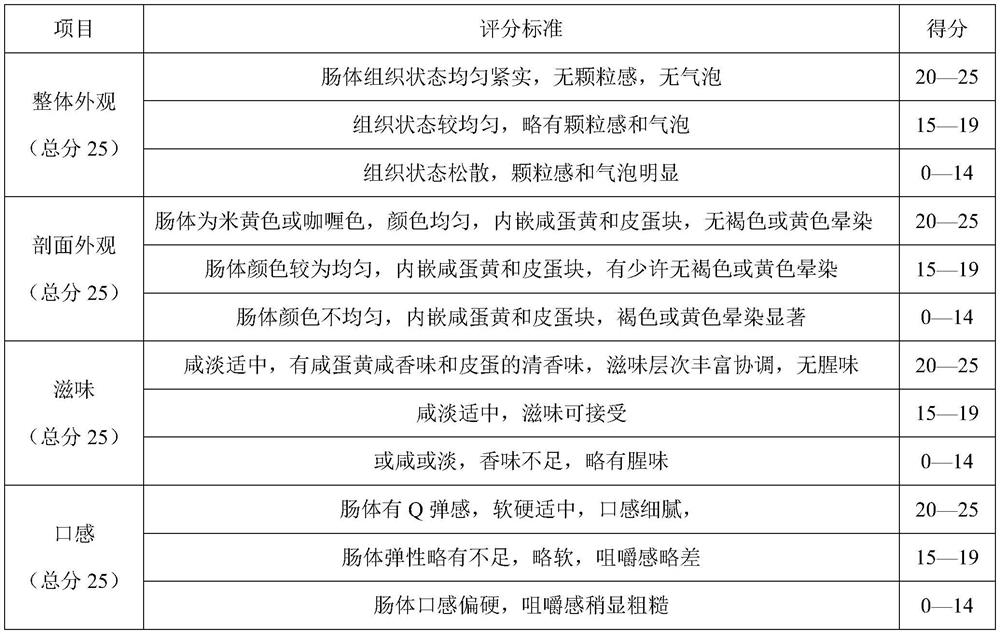

A production method and egg sausage technology are applied in the directions of food ingredients as coating agents, food ingredients as thickeners, food freezing, etc., and can solve the problems of slight egg smell, insufficient gloss, and insufficient elasticity of taste Q. , to achieve the effect of obvious sandy feeling, rich nutrition, rich and harmonious taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A three-color egg sausage is composed of the following raw materials by weight percentage: 14% of preserved preserved egg, 14% of raw salted egg yolk, 37% of egg white, 20% of egg yolk, 4% of glutinous rice flour, 1.6% of white sugar, and 0.2% of compound phosphate. %, salt 1.5%, water-soluble ginger powder 0.4%, water-soluble pepper powder 0.3%, edible oil 4%, water 3%.

[0035] Adopt above-mentioned raw material to prepare the method for three-color egg sausage, concrete steps are as follows:

[0036] (1) The egg yolk is placed in a homogenizer, and is homogenized for 5min at a rotating speed of 3500r / min and 60MPa to obtain egg yolk liquid;

[0037] (2) After freezing the egg white at -18°C for 12 hours, thaw it at 25°C for 3 hours until the egg white liquid is completely melted, then place it in a liquid ultra-fine pulverizer, and perform ultra-fine pulverization at 4 ° C for 3 minutes to obtain egg white liquid;

[0038] (3) the obtained egg yolk liquid of step (1...

Embodiment 2

[0043] A three-color egg sausage is composed of the following raw materials by weight: 12% of preserved preserved egg, 12% of raw salted egg yolk, 40% of egg white, 20% of egg yolk, 4% of glutinous rice flour, 1.6% of white sugar, and 0.2% of compound phosphate. %, salt 1.5%, water-soluble ginger powder 0.3%, water-soluble pepper powder 0.4%, edible oil 3%, water 5%.

[0044] Adopt above-mentioned raw material to prepare the method for three-color egg sausage, concrete steps are as follows:

[0045] (1) The egg yolk is placed in a homogenizer, and is homogenized for 5min at 60Mpa and a rotating speed of 3500r / min to obtain egg yolk liquid;

[0046](2) After freezing the egg white at -18°C for 12 hours, thaw it at 25°C for 3 hours until the egg white liquid is completely melted, then place it in a liquid ultra-fine pulverizer, and perform ultra-fine pulverization at 4 ° C for 4 minutes to obtain an egg white liquid;

[0047] (3) the obtained egg yolk liquid of step (1) and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com