Automobile flywheel drilling device with mechanical automatic positioning function

An automatic positioning and drilling device technology, applied in positioning devices, boring/drilling, drilling/drilling equipment, etc., can solve the problems of water waste, no filter, anti-blocking and cleaning, and unfavorable use by staff. , to achieve the effect of ensuring normal use, saving water resources and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

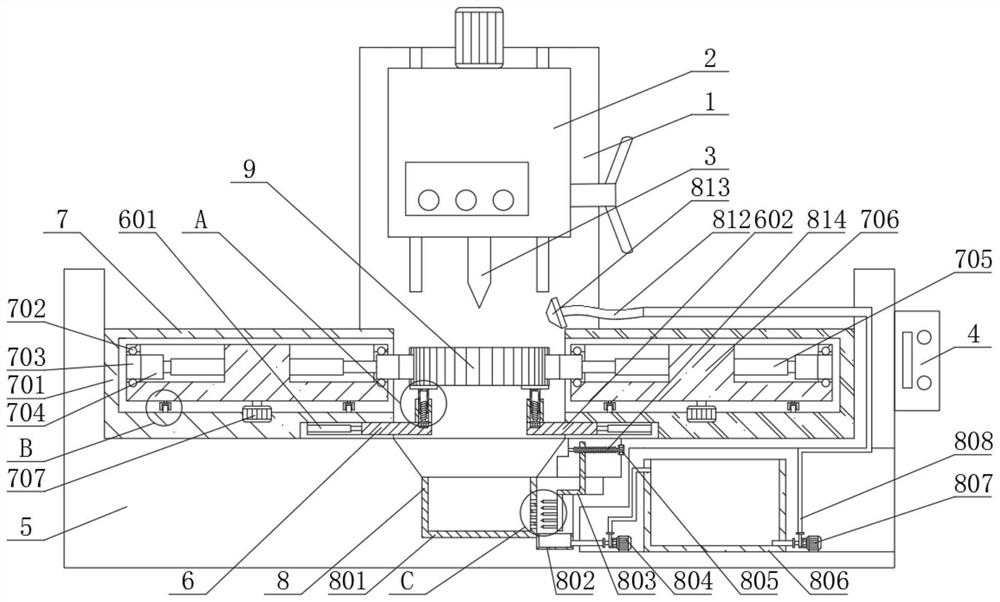

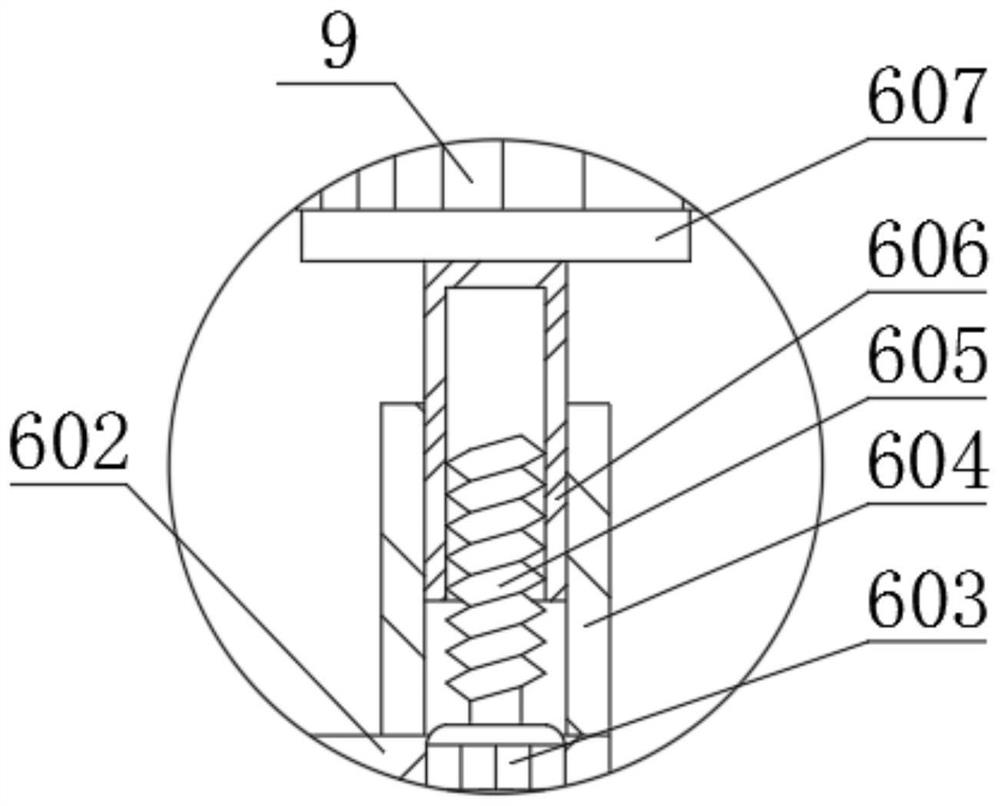

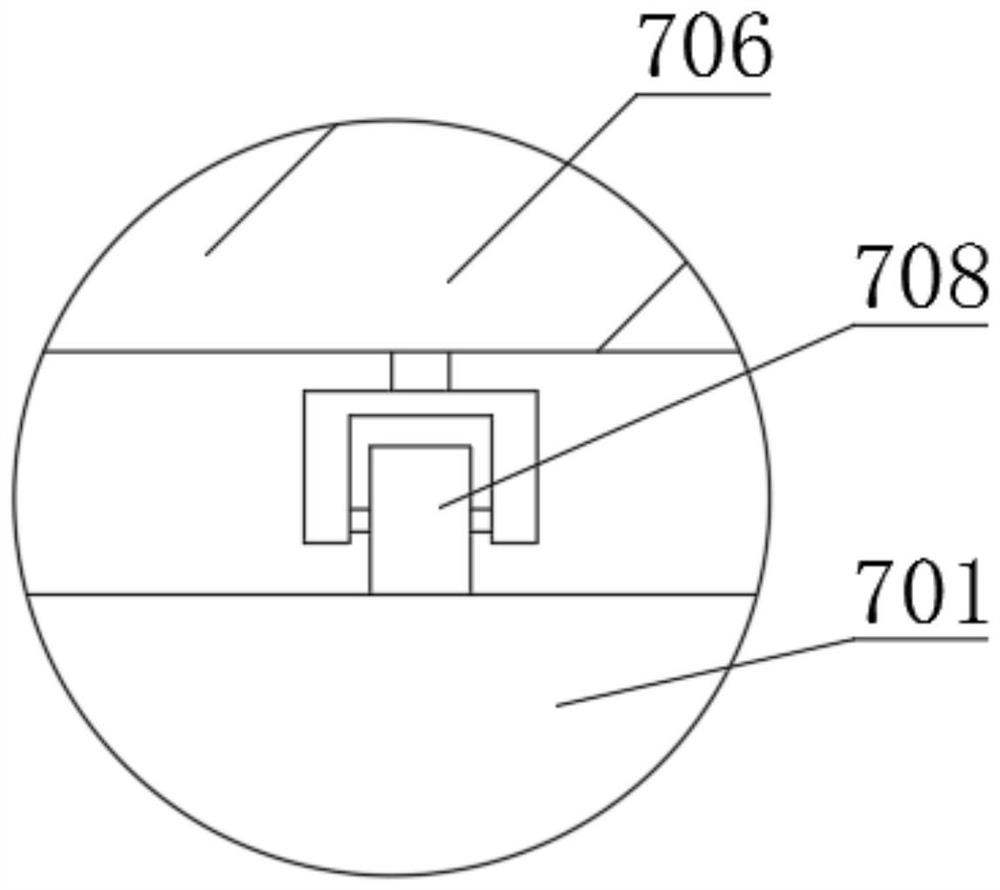

[0027] see Figure 1-7 , the present invention provides a technical solution:

[0028] An automobile flywheel drilling device with mechanical automatic positioning function, comprising a base 5, a fixed base 1 is fixedly connected to the rear side of the top of the base 5, the front end of the fixed base 1 is fixedly connected to a numerical control case 2, and the inner side of the numerical control case 2 is fixedly connected There is a drill bit 3, a controller 4 is fixedly connected to the right end of the base 5, a positioning device 7 is fixedly connected to the top of the base 5, a support device 6 is fixedly connected to the bottom end of the positioning device 7, and a cooling device 8 is fixedly connected to the inner side of the base 5, The inner side of the positioning device 7 is provided with a flywheel 9, and the positioning device 7 includes a positioning plate 701, a ball 702, a positioning block 703, a connecting block 704, a second electric telescopic rod 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com