Welding structure and method for ultra-pure copper target

A welding method and welding structure technology, applied in the direction of welding/welding/cutting articles, welding equipment, welding equipment, etc., can solve the problem that the uniformity of the target sputtering rate cannot be guaranteed, abnormal phenomena in the target sputtering process, sputtering In order to improve the welding effect, prevent abnormal phenomena and increase the welding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

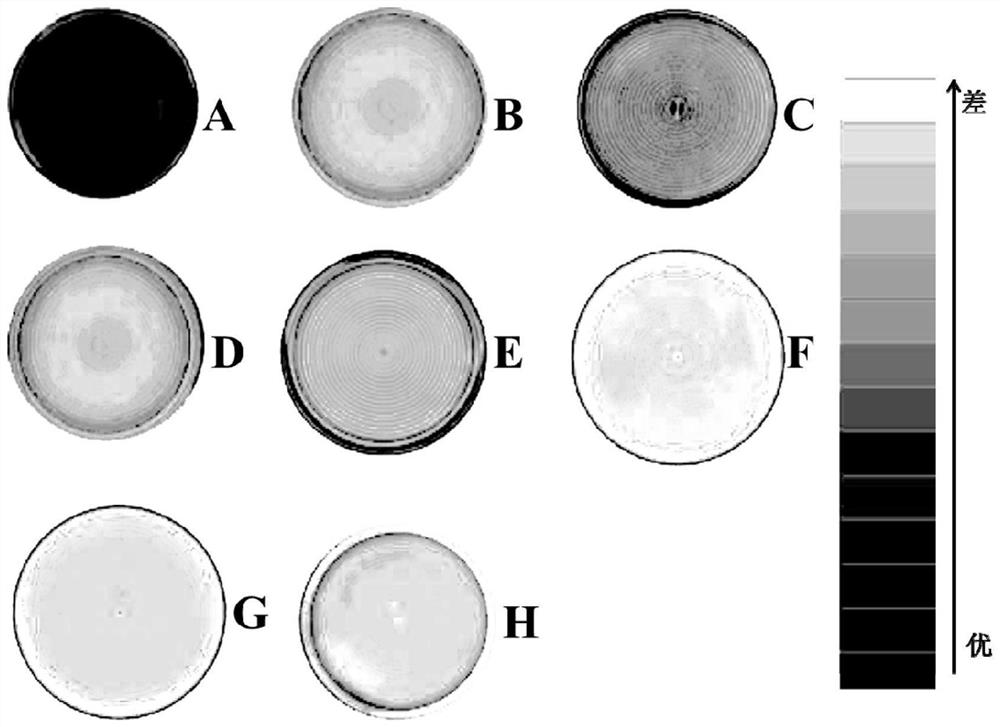

Embodiment 1

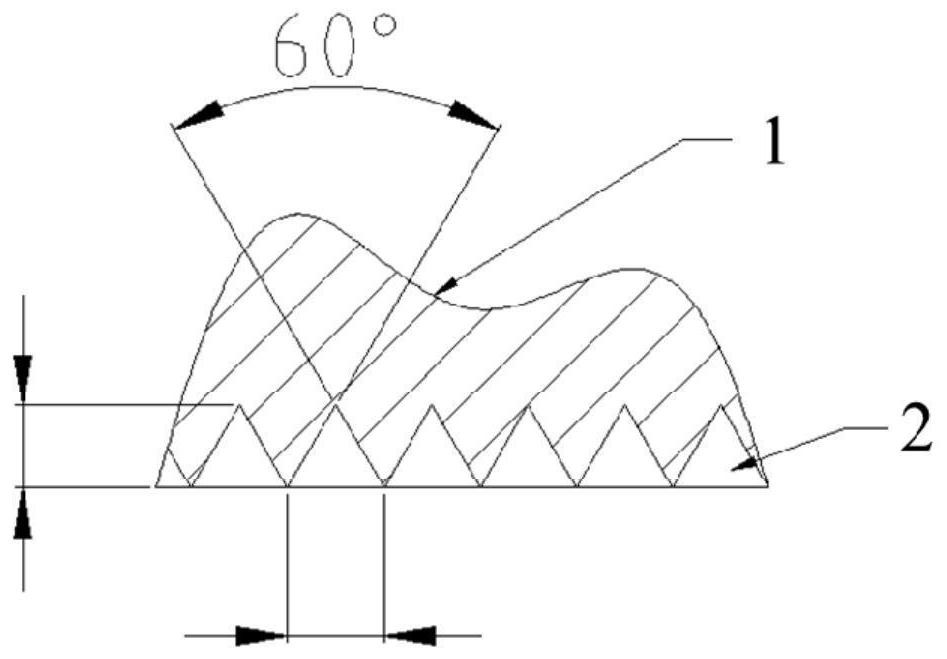

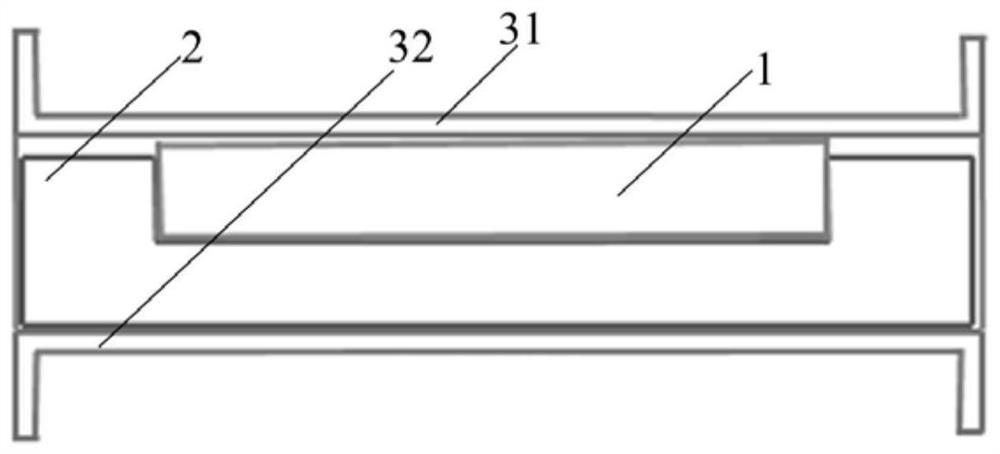

[0062] This embodiment provides an ultra-high-purity copper target welding structure, such as figure 1 As shown, the welding structure includes an ultra-high-purity copper target 1, and a target back plate 2 welded with the ultra-high-purity copper target; the copper purity of the ultra-high-purity copper target 1 is 99.9999wt% , the target back plate 2 is a CuZn alloy back plate (Cu content 61.8wt%, Zn content 36.6wt%).

[0063] The target back plate 2 includes a welding surface, and the welding surface is provided with toothed threads; the pitch of the threads is 0.15mm, and the depth of the threads is 0.12mm; the angle of the tip angle of the threads is 60° , the roughness of the welding surface of the target back plate is 0.4 μm.

Embodiment 2

[0065] This embodiment provides an ultra-high-purity copper target welding structure, the welding structure includes an ultra-high-purity copper target, and a target back plate welded with the ultra-high-purity copper target; the ultra-high-purity copper The copper purity of the target is 99.99991 wt%, and the target back plate is a CuCr alloy back plate (96.8 wt% Cu content, 0.5 wt% Cr content).

[0066] The target back plate includes a welding surface, and the welding surface is provided with toothed threads; the pitch of the threads is 0.25mm, the depth of the threads is 0.15mm, and the angle of the tip angle of the threads is 55°, The roughness of the welding surface of the target back plate is 0.3 μm.

Embodiment 3

[0068] This embodiment provides an ultra-high-purity copper target welding structure, the welding structure includes an ultra-high-purity copper target, and a target back plate welded with the ultra-high-purity copper target; the ultra-high-purity copper The copper purity of the target is 99.99992wt%, and the target back plate is a CuCr alloy back plate (Cu content 97.1wt%, Cr content 0.4wt%).

[0069] The target back plate includes a welding surface, and the welding surface is provided with toothed threads; the pitch of the threads is 0.15mm, the depth of the threads is 0.10mm, and the angle of the tip angle of the threads is 55°, The roughness of the welding surface of the target back plate is 0.8 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com