Wooden door one-time forming mold and forming method

A molding method and wooden door technology, which can be applied to household appliances, other household appliances, wood processing appliances, etc., can solve problems such as cumbersome operation, achieve simple and convenient operation, reduce production cycle, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

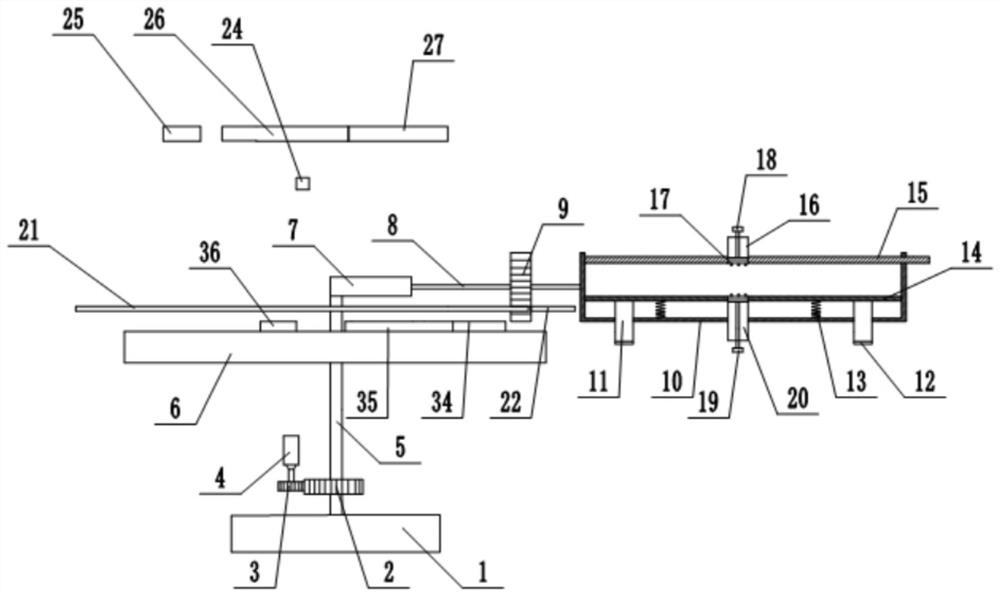

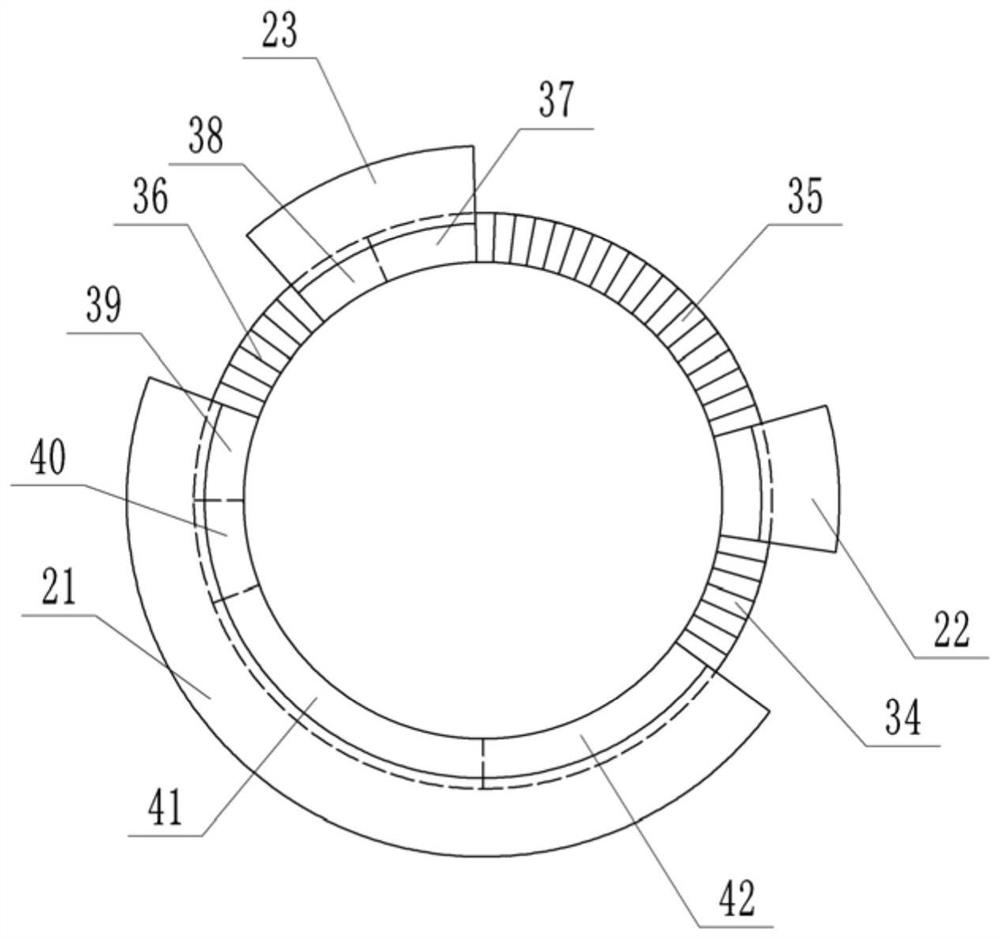

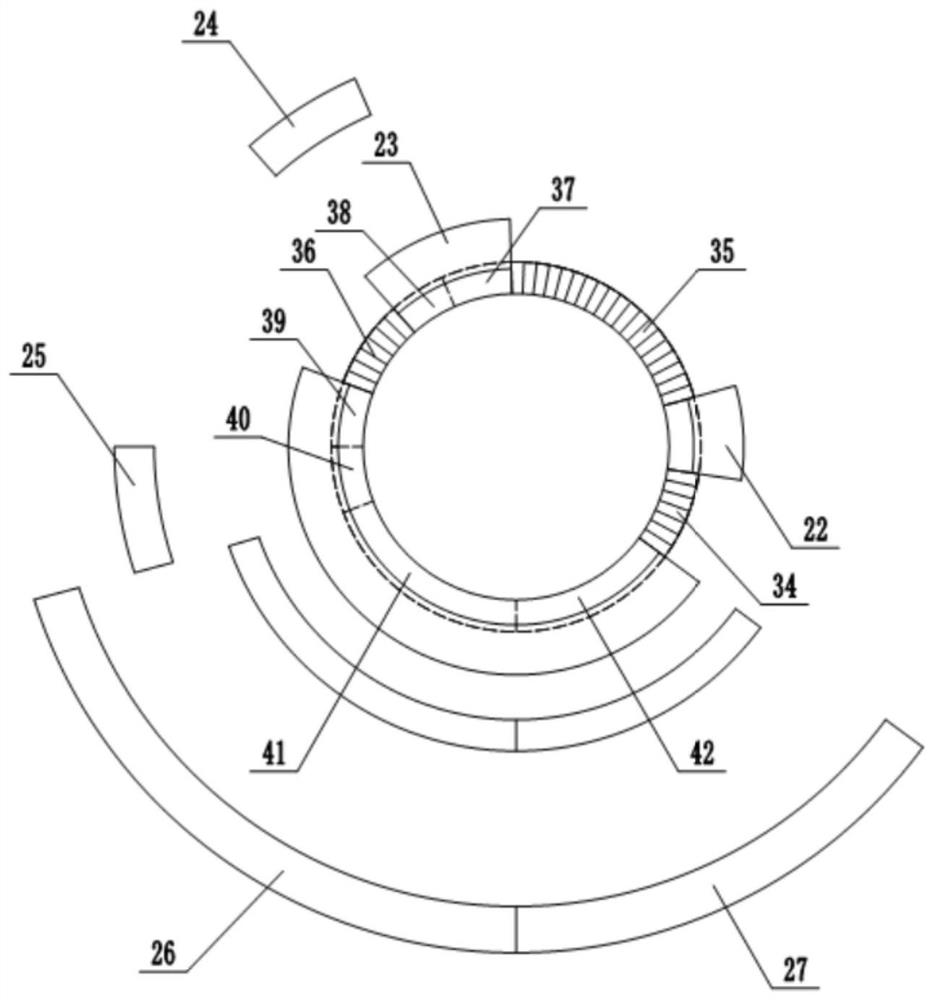

[0044] Basic as attached Figure 1-Figure 4 Shown: a mold for one-time forming of a wooden door, including a frame, a mold body 10 and a rotating assembly that drives the mold body 10 to rotate. The rotating assembly in the present embodiment comprises a fixed ring 6, a gear 9, a rotating rod 8, a fixed block 7 and a drive shaft 5, a support block 1 is welded on the frame, the drive shaft 5 is vertically arranged, and the bottom end of the drive shaft 5 passes through The bearing is rotatably connected to the support block 1, the driving shaft 5 is coaxially welded with the driven gear 2, the motor 4 is fixed on the frame by screws, and the output shaft of the motor 4 is coaxially welded with the driving gear 3, the driving gear 3 and Driven gear 2 meshes. The fixed ring 6 is fixed on the frame by screws, the fixed ring 6 is arranged horizontally, the drive shaft 5 passes through the fixed ring 6, and the fixed block 7 is welded on the top of the drive shaft 5 . Rotating rod...

Embodiment 2

[0060] combine Figure 5-Figure 6 As shown, the right side of the fixed ring 6 is provided with a receiving assembly, and the receiving assembly in this embodiment is opposite to the discharge section 42; the receiving assembly includes a base 29 and a receiving plate 32, and a drive for driving is provided between the receiving plate 32 and the base 29. The cylinder 31 that the receiving plate 32 moves vertically, the cylinder 31 is fixed on the base 29 by screws, the telescopic rod 30 is connected between the receiving plate 32 and the base 29, the bottom of the telescopic rod 30 is welded on the base 29, and the receiving plate 32 slides laterally Connected on the cylinder rod of the cylinder 31 and the top of the telescopic rod 30, the bottom of the concrete receiving plate 32 is provided with a chute, the top of the cylinder rod of the cylinder 31 and the top of the telescopic rod 30 are located in the chute, and on the receiving plate 32 An arc-shaped slot 33 for passing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com