A prefabricated construction method of reinforced concrete segments for shield tunneling construction

A reinforced concrete and construction method technology, applied in ceramic molding machines, applications, manufacturing tools, etc., can solve the problems of good durability, high impermeability, reduce water leakage rate, etc. Good sex, the effect of increasing penetration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

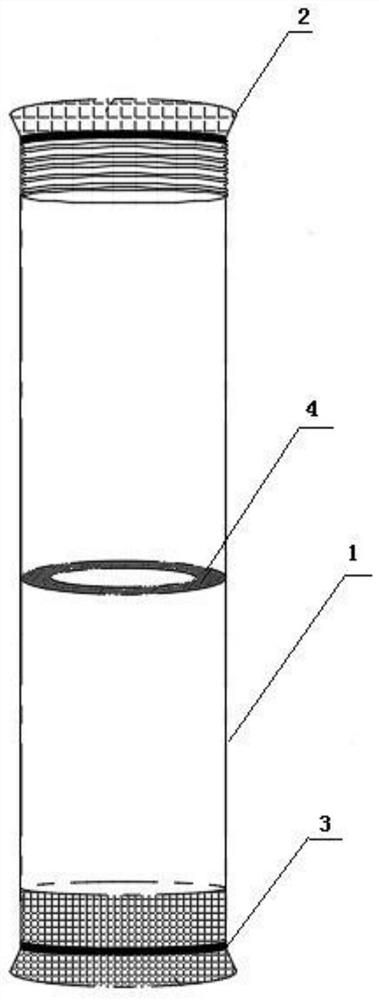

[0059] Attached to the manual figure 1 Specific embodiments of the construction method for prefabricating reinforced concrete segments for shield tunneling construction described in this application are described in detail.

[0060] The construction method for prefabricating reinforced concrete segments for shield tunneling construction includes the following steps:

[0061] Step 1, manufacturing, assembling and cleaning the segment mold;

[0062] Step 2, manufacturing steel cage;

[0063] Step 3, install the circular steel edge water stop ring 4 and the two water stop caps 2 on the embedded pipe 1;

[0064] Step 4, fix the assembled pre-embedded pipe 1 on the reinforcement cage, and place the reinforcement cage in the segment mold;

[0065] Step 5, using cement, water, sand, stones, water reducing agent and fly ash to mix concrete;

[0066] Step 6, spread concrete into the segment mold, vibrate and plaster the concrete;

[0067] Step 7, steam curing the concrete segment; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com