Cyclone type supercritical water oxidation reactor

A supercritical water oxidation and reactor technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc., can solve problems such as inorganic salt particle deposition, achieve compact structure, ensure long-term stable operation, occupy Small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

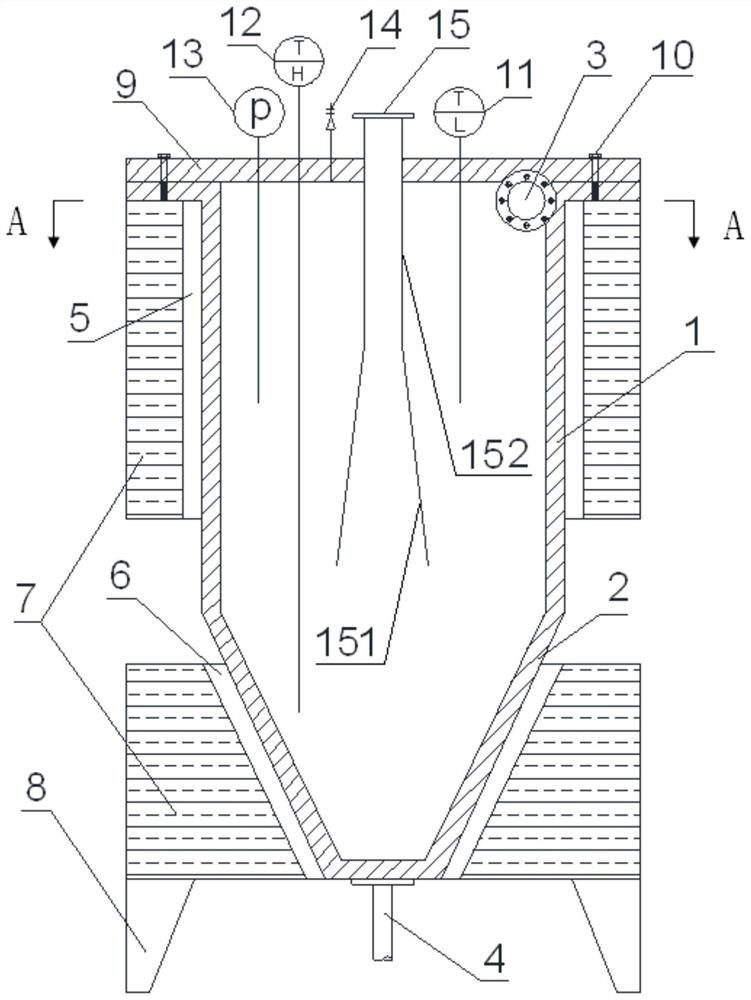

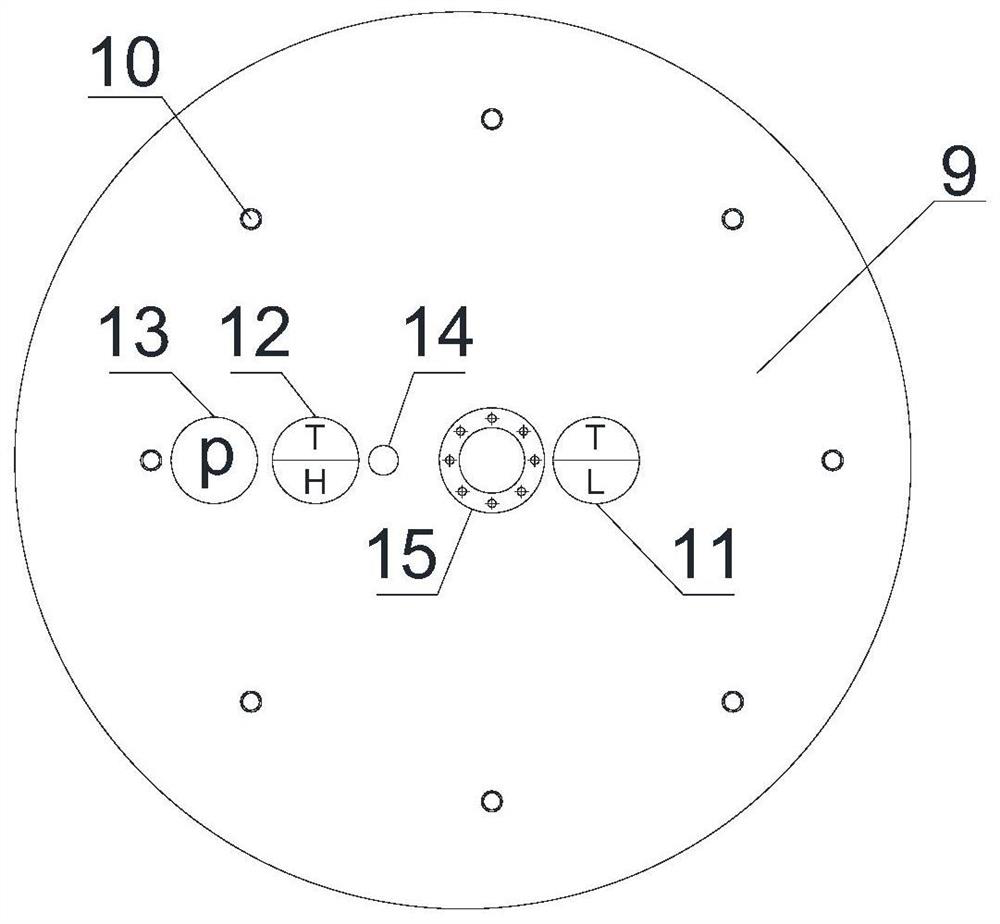

[0022] Such as figure 1 Shown is a cyclone supercritical water oxidation reactor according to an embodiment of the present invention, which includes a reactor cylinder, an electric heating module wrapped around the outer periphery of the reactor cylinder, and the reactor cylinder Connected sealing cap. The reactor barrel is connected with a sealing cap to seal the reactor barrel.

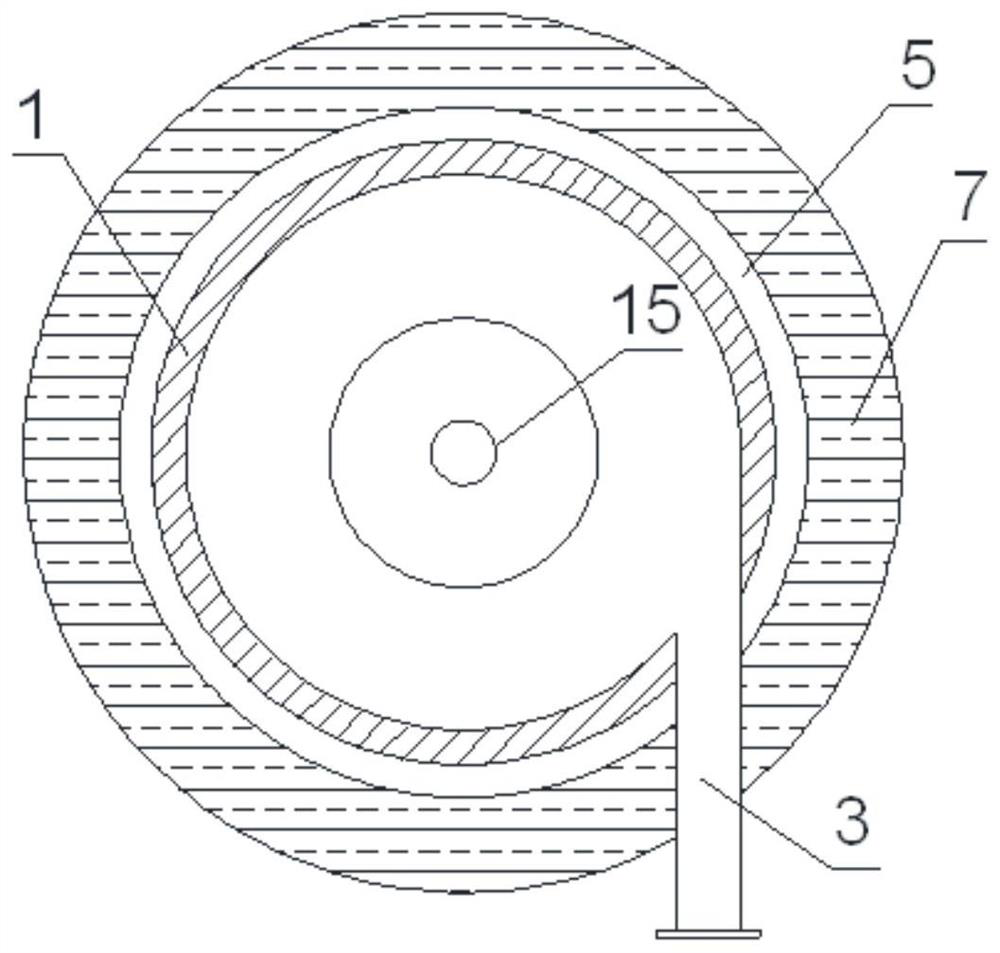

[0023] Such as figure 1 As shown, the reactor shell includes a cylindrical shell 1, a conical shell 2 connected to the cylindrical shell 1 and arranged below it, a water inlet pipe 3 arranged on the inner wall of the cylindrical shell 1 and The salt discharge pipe 4 arranged at the bottom of the conical cylinder 2. The lower end of the cylindrical barrel 1 is welded to the upper end of the conical barrel 2, and the tip of the conical barrel 2 is downward, which is be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com