Torsion spring suitable for high frequency vibration motor, high frequency vibration motor and application thereof

A high-frequency vibration and torsion spring technology, applied in torsion springs, reciprocating/oscillating/vibrating magnetic circuit components, electrical components, etc. Frequency instability and other problems, to achieve the effect of high deflection efficiency, simple structure and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

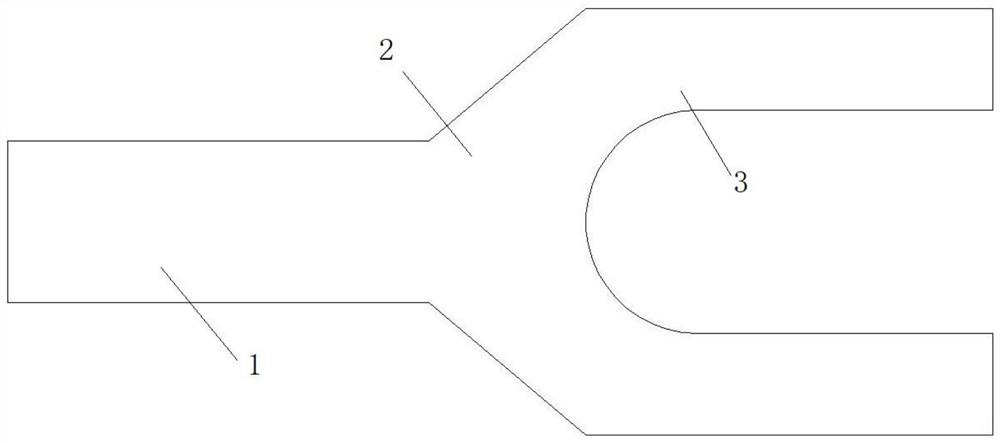

[0028] A torsion spring, the spring body is in the shape of a flat plate, consisting of a fixed section and a twisted section; one end of the twisted section is connected to the fixed section, and the other end is a U-shaped or V-shaped fork spring with the fixed section as the axis of symmetry. The end of the spring is the stressed end; the other end of the fixed section is the fixed end.

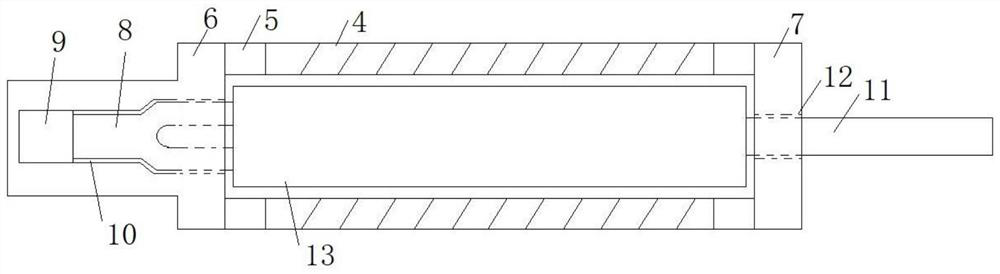

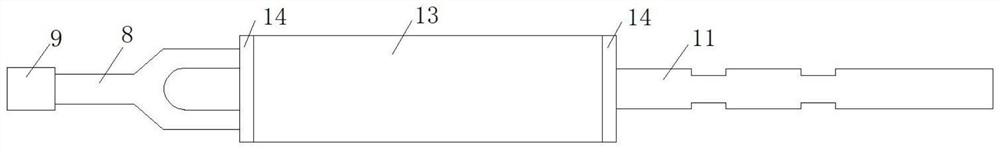

[0029] A high-frequency vibration motor, which is composed of a stator core and a rotor core; the stator core is U-shaped, in order to reduce the volume, the stator core can be integrated with the U-shaped base, and the two side walls of the stator core can be used as U-shaped A part of the two side walls of the U-shaped base; the two ends of the U-shaped base are respectively provided with a first end cover and a second end cover; the rotor core is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com